Great Wall Hover. Manual - part 59

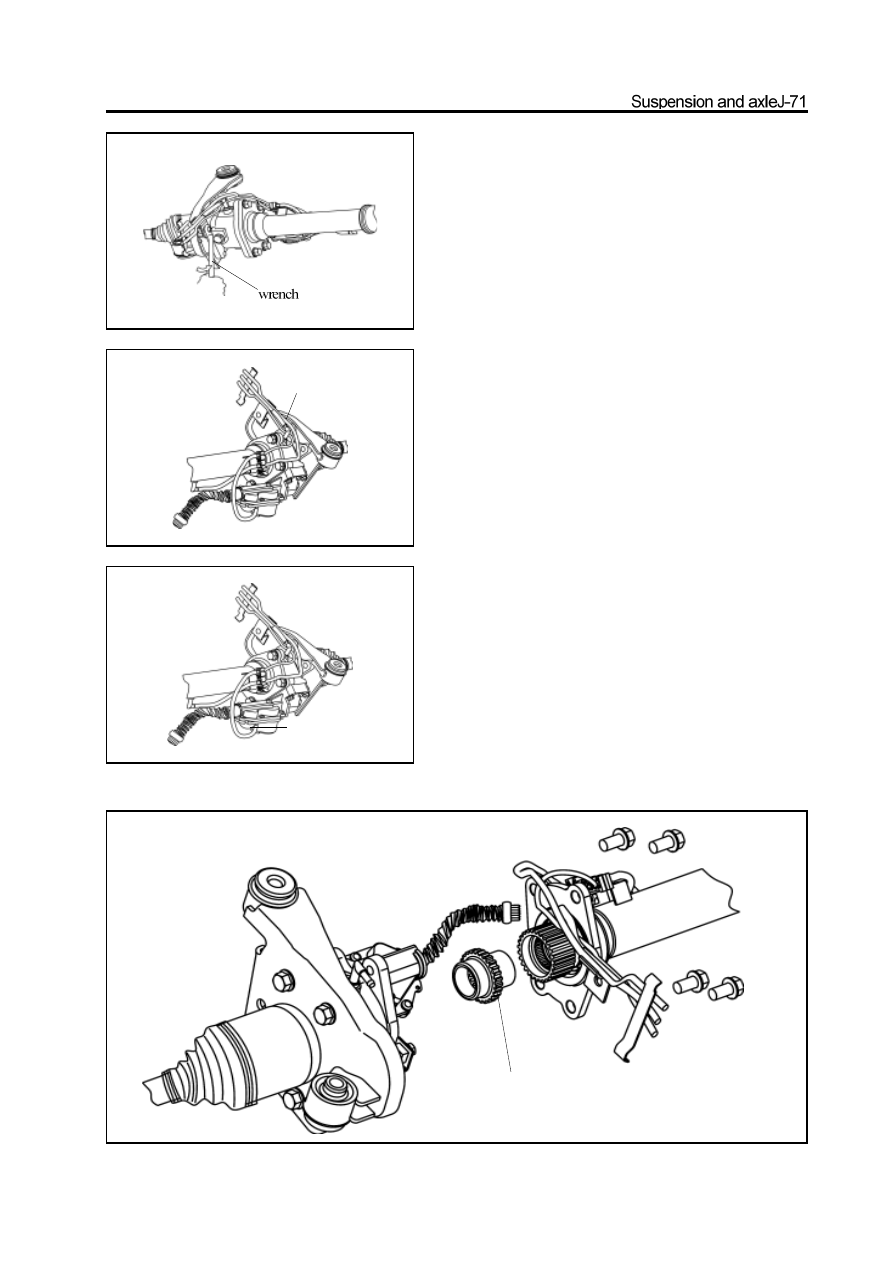

Replacement of major semiaxle oil seal

1. Make the electric clutch is in the 4WD status,

them stop the engine and remove the front drive

axle assembly (see the disassembly of front reducer

assembly)

2. Use the wrench to screw off the bolt which fix the

front axle vent tube connectorassemblyonventtubeb

racket bolt

3. Disconnect the connector between vent tube of

electric clutch housing and front drive axle vent tube

connector assembly

4. Disconnect the connector between the vent tubes

on the electric clutch and vent tube connector

assembly.

5. Remove the bolt which is used to fix the electric

clutch housing and front axle tube flange; use the

brass bar to open the electric clutch housing and take

out the mechanical wheel of separator.

Caution: The lubrication oil will flow out when sepa-

rate the electric clutch housing from the front axle

flange. It should use the container to hold it.

mechanical wheel of separator

disconnect the place

disconnect the place