Daewoo Musso. Manual - part 206

WHEEL ALIGNMENT 2B-5

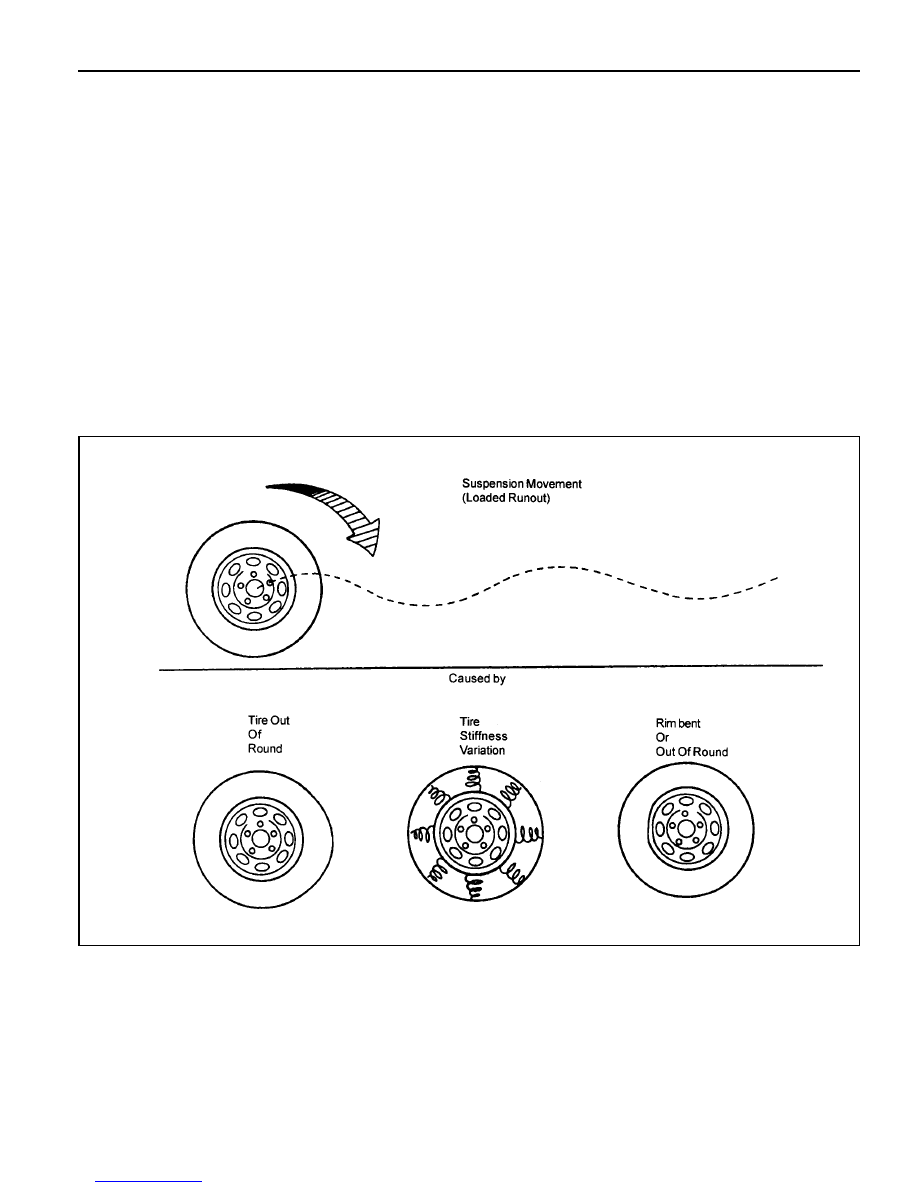

VIBRATION DIAGNOSIS

Wheel imbalance causes most highway speed vibration

problems. A vibration can remain after dynamic

balancing because:

l

A tire is out of round.

l

A rim is out of round.

l

A tire stiffness variation exists.

Measuring tire and wheel free runout will uncover only

part of the problem, All three causes, known as loaded

radial runout, must be checked using method of

substituting known good tire and wheel assemblies on

the problem vehicle.

Preliminary Checks

Prior to performing any work, always road test the car

and perform a careful visual inspection for:

l

Obvious tire and wheel runout.

l

Obvious drive axle runout.

l

Improper tire inflation.

l

Incorrect trim height.

l

Bent or damaged wheels.

l

Debris build-up on the tire or the wheel.

l

Irregular or excessive tire wear.

l

Improper tire bead seating on the rim,

l

Imperfections in the tires, including: tread

deformations, separations, or bulges from impact

damage. Slight sidewall indentations are normal and

will not affect ride quality.

Tire Balancing

Balance is the easiest procedure to perform and should

be done first if the vibration occurs at high speeds. Do

an off-vehicle, two-plane dynamic balance first to correct

any imbalance in the tire and wheel assembly.

An on-vehicle finish balance will correct any brake drum,

rotor, or wheel cover imbalance, If balancing does not

correct the high-speed vibration, or if the vibration occurs

at low speeds, runout is the probable cause.