Daewoo Musso. Manual - part 31

1B1-60 M162 ENGINE MECHANICAL

Tools Required

000 589 01 10 00 Box Wrench Insert

104 589 01 01 00 Spanner

Removal Procedure

1. Turn the crankshaft and position the No. 1 cylinder piston

at BTDC 30°.

2. Remove the alternator.

3. Remove the chain tensioner.

4. Remove the cylinder head front cover and the upper guide

rail.

6. Unscrew the exhaust camshaft sprocket bolt and remove

the sprocket.

7. Separate the chain from the intake camshaft sprocket and

put the chain not to be dropped into timing case.

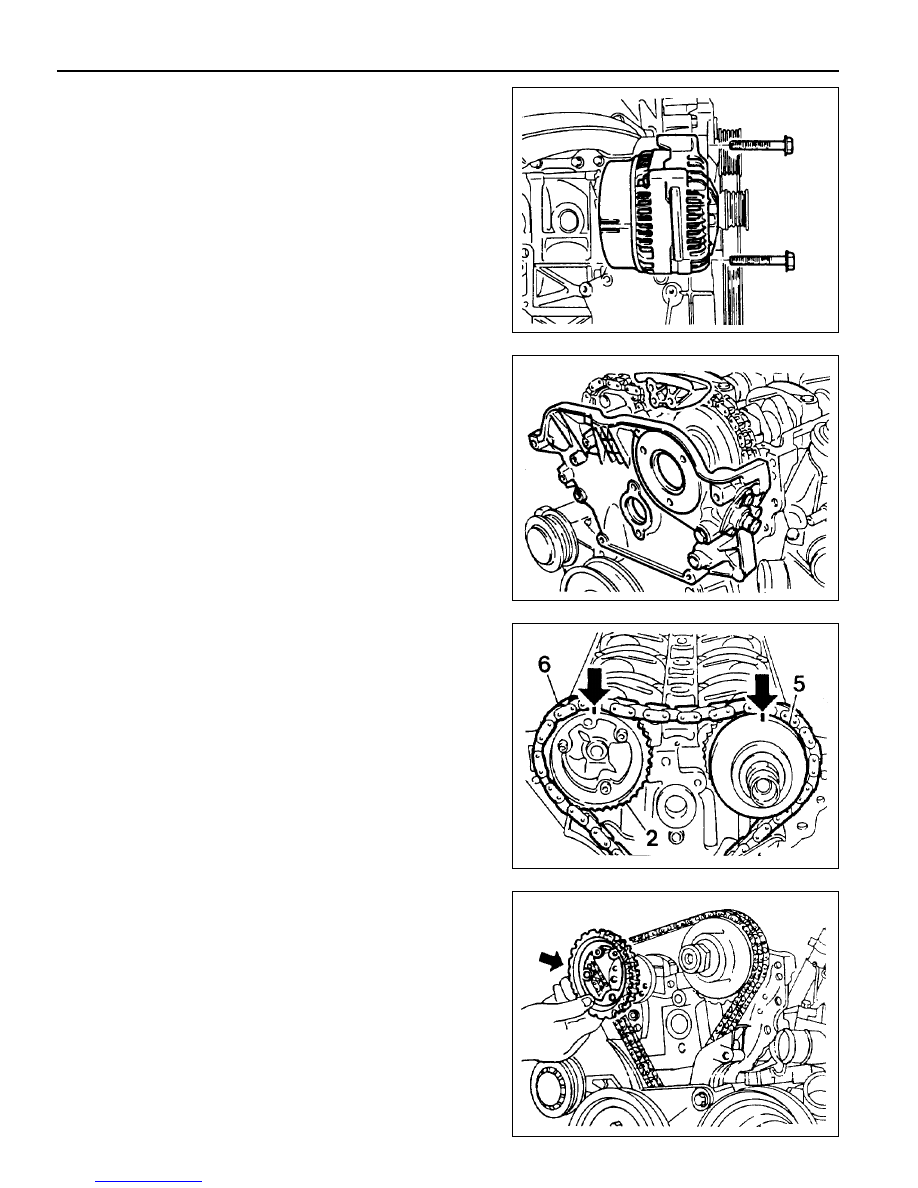

5. Put the alignment marks (arrows) on the camshaft sprocket

(2, 5) and the timing chain (6).