Daewoo Matiz (2003 year). Manual - part 17

1E – 20 ENGINE ELECTRICAL

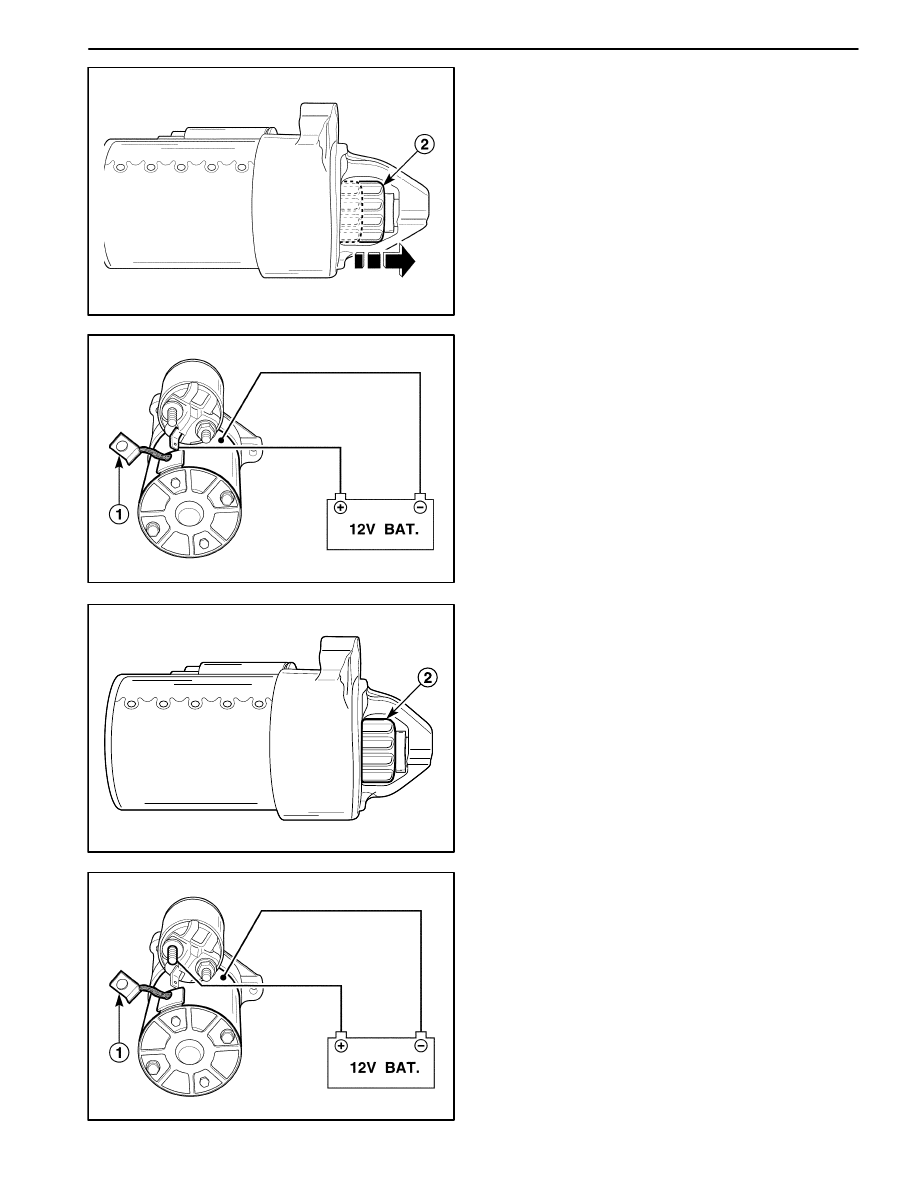

D102E704

D

Inspect the pinion gear’s moving to the outside (2).

D

If the pinion gear does not move outside, replace

the magnetic switch.

D102E705

4. Solenoid hold-in test.

D

Disconnect the starter motor terminal M (1).

D

Connect the 12-volt battery lead to the starter mo-

tor terminal S and body.

Notice: Complete the testing in a minimum amount of

time to prevent overheating and damaging the solenoid.

D102E706

D

Check the pinion gear’s moving to the outside (2).

D

If the pinion gear move to the inside, the circuit is

open. Replace the magnetic switch.

D102E707

5. Solenoid return test.

D

Disconnect the starter motor terminal M (1).

D

Connect the 12-volt battery lead to the starter mo-

tor terminal S and body.

Notice: Complete the testing in a minimum amount of

time to prevent overheating and damaging the solenoid.