Daewoo Matiz (2003 year). Manual - part 16

1E – 16 ENGINE ELECTRICAL

D12E508A

35–41 N

S

m

68–83 N

S

m

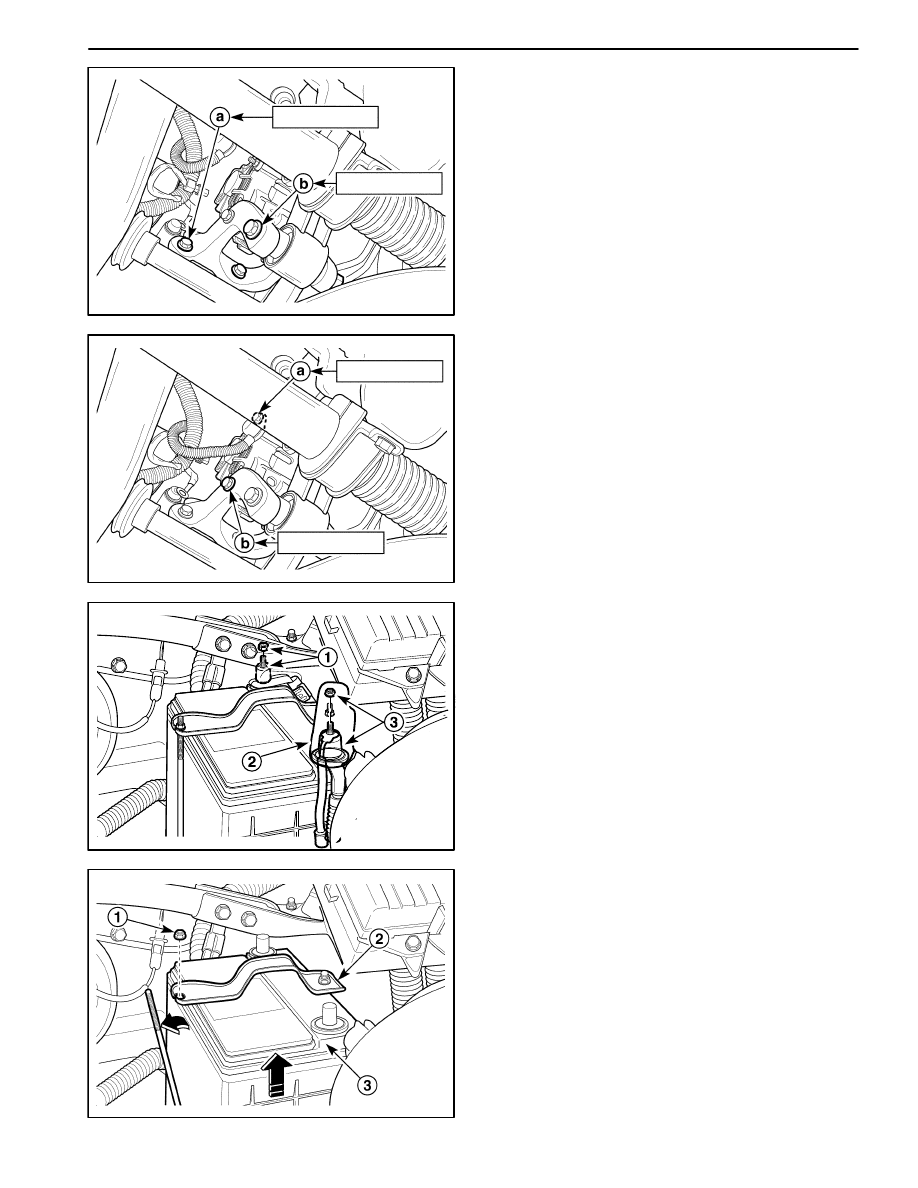

Installation Procedure

1. Install in the reverse order of removal except genera-

tor driver velt.

2. Install the engine mounting lower bracket bolts and

nut.

Tighten

D

Tighten the engine mounting lower bracket bolts to

35–41 N

S

m (25–30 lb-ft) (a).

D

Tighten the engine mounting lower bracket, attach-

ing reaction rod bolt and nut to 68–83 N

S

m (50–61

lb-ft) (b).

D12E509A

4–7 N

S

m

18–28 N

S

m

3. Install the bolts and nut.

Tighten

D

Tighten the generator adjusting bolt to 4–7 N

S

m

(35–62 lb-in) (a).

D

Tighten the generator lower bracket bolt and nut to

18–28 N

S

m (13–21 lb-ft) (b).

D

Inspect the generator drive belt tension.

D12E511A

BATTERY

Removal Procedure

1. Disconnect the negative battery cable and then dis-

connect the positive battery cable.

D

Remove the battery cable nut to disconnect the

negative battery cable (1).

D

Remove the battery terminal cap (2).

D

Remove the battery cable nut to disconnect the

positive battery cable (3).

D102E512

2. Remove the battery.

D

Remove the battery rod nut (1).

D

Remove the battery rod (2).

D

Remove the battery (3).