DAF LF45, LF55 Series. Manual - part 291

©

200416

4-1

Inspection and adjustment

BE ENGINE FUEL SYSTEM

ΛΦ45/55 series

4

2

4. INSPECTION AND ADJUSTMENT

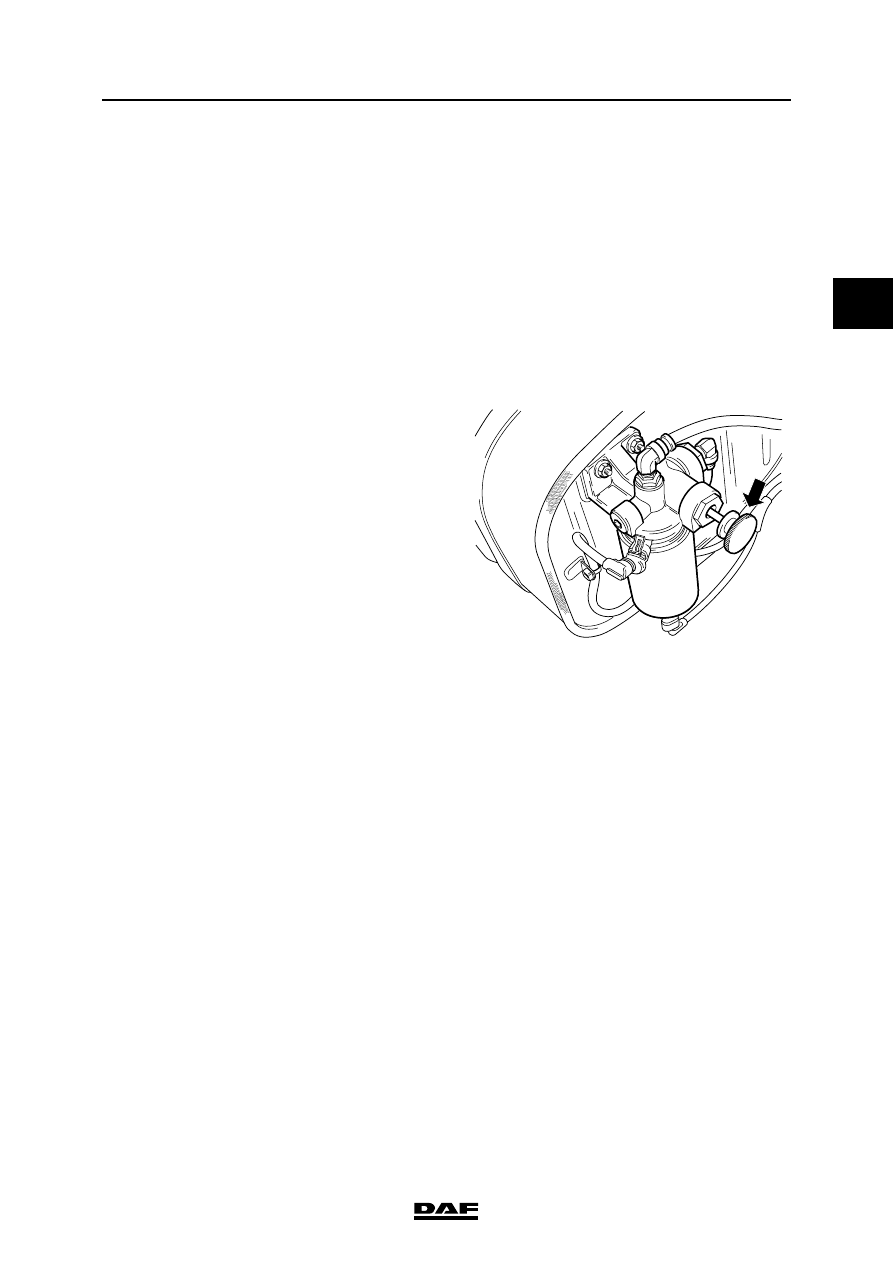

4.1 BLEEDING THE FUEL SYSTEM

Stop pumping as soon as a greater

resistance is felt. If you continue

pumping, the fuel system may

become internally damaged.

Note:

When the hand pump is used, the fuel system will

be automatically bled. Air will be fed back to the

tank through the return pipe.

1.

Unscrew the button of the primer pump and

pull it out.

2.

Use the primer pump until a clearly higher

resistance is perceptible.

3.

Press the button and tighten it.

}

G0 00 209