DAF LF45, LF55 Series. Manual - part 257

©

200508

3-3

Inspection and adjustment

ALLISON 1000 & 2000 AUTOMATIC GEARBOXES

ΛΦ45/55 series

3

7

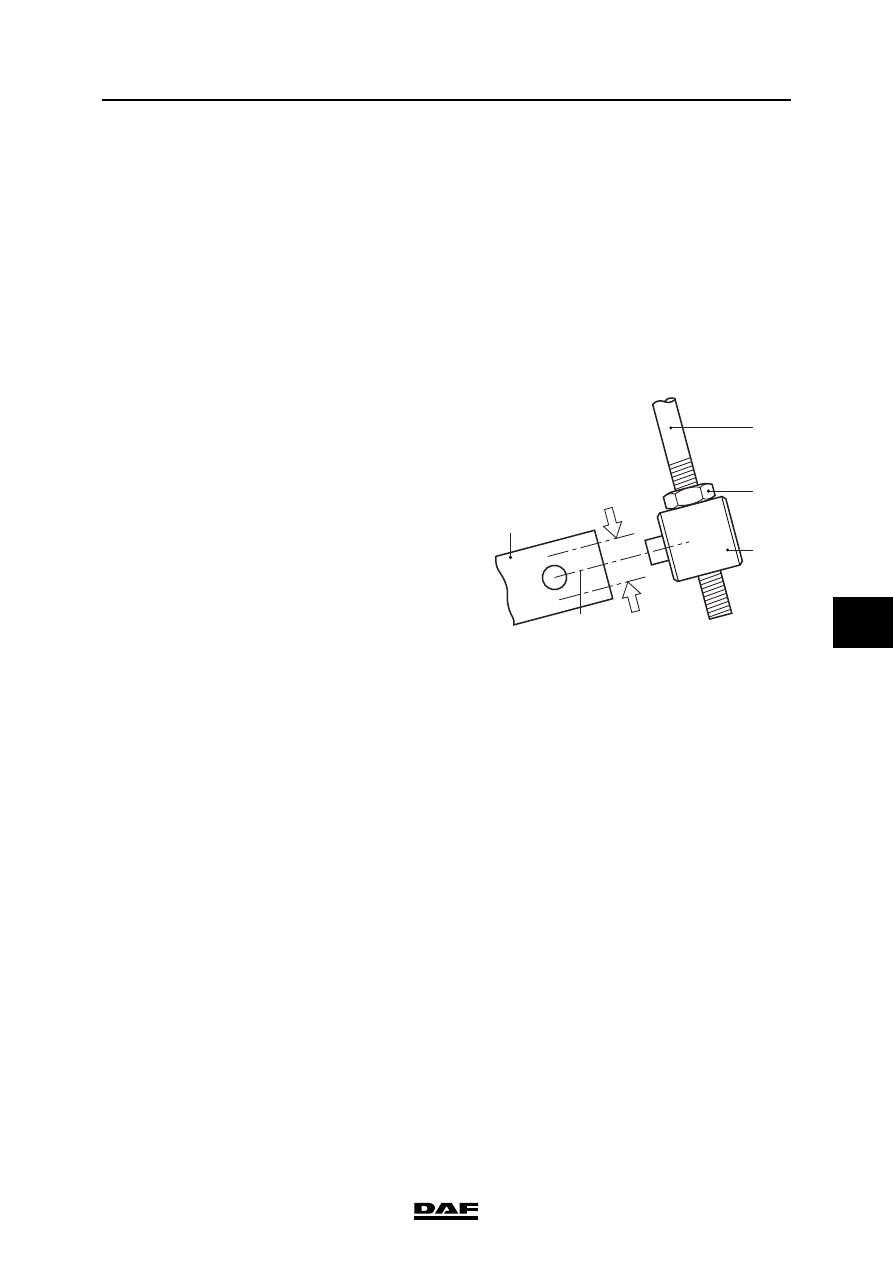

3.2 INSPECTING AND ADJUSTING SELECTOR CABLE

Inspecting selector cable

1.

Check that the selector cable has been fitted

to the selector arm so that the connecting pin

can move freely in every gear. If necessary,

adjust the selector cable.

Adjusting selector cable

1.

Chock the wheels so that the vehicle cannot

roll.

2.

Position the selector lever in neutral.

3.

Remove the selector cable (2) from the

selector arm (1), if applicable.

4.

Unscrew the lock nut (3) from the connecting

pin (4).

5.

Determine the central position (C) of the

connecting pin by first pushing the selector

cable in (A) and then pulling it out (B). Mark

the limit positions of the connecting pin.

6.

Move the connecting pin so that when in the

central position (C) it is level with the bore in

the selector arm.

7.

Tighten the lock nut of the connecting pin.

8.

Install the connecting pin in the selector arm

bore and tighten the lock nut to the specified

torque. See "Technical data".

9.

Check in every gear that the positions of the

selector lever in the cab correspond

precisely to the selected gear.

2

1

A

B

C

3

4

V3 00 483