DAF LF45, LF55 Series. Manual - part 258

©

200508

4-3

Removal and installation

ALLISON 1000 & 2000 AUTOMATIC GEARBOXES

ΛΦ45/55 series

3

7

4.2 REMOVING AND INSTALLING SELECTOR SWITCH

Removing selector switch

1.

Remove the selector cable from the selector

arm.

2.

Remove the attachment nut from the

selector shaft.

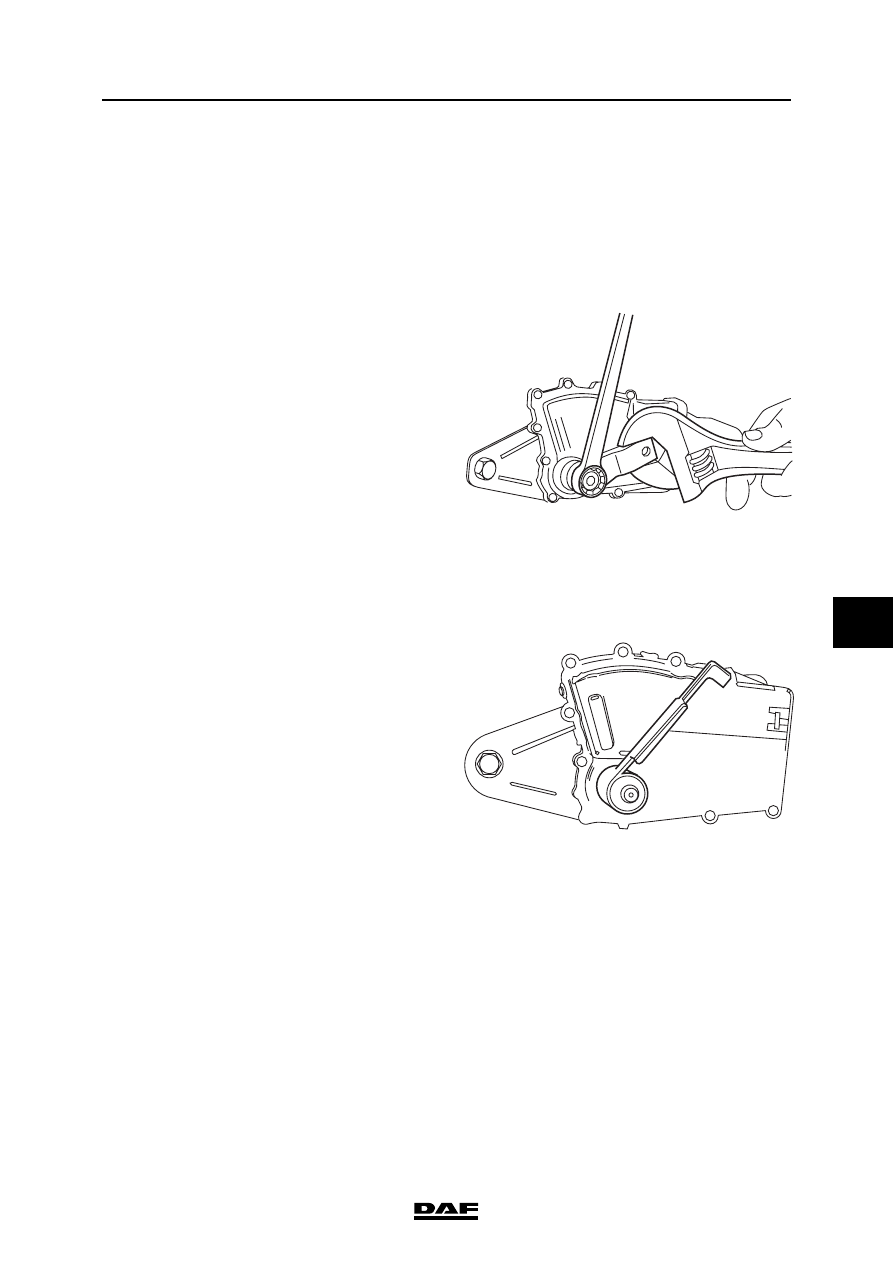

The selector shaft must not be

turned while the attachment nut is

being loosened or tightened. While

loosening or tightening the

attachment nut, lock the selector

shaft using the selector arm and an

appropriate tool.

3.

Remove the selector arm.

4.

Remove the connectors from the selector

switch.

5.

Take the attachment bolts out of the selector

switch and remove it.

Fitting selector switch

1.

Put the selector shaft in the neutral position.

See the marks on the gearbox housing.

2.

Put the selector switch in the neutral position

using special tool (DAF no. 1451992).

3.

Fit the selector switch, together with the

special tool, over the selector shaft and onto

the gearbox housing.

4.

Install the selector switch attachment bolts

and tighten them to the specified torque. See

"Technical data".

5.

Fit the selector arm onto the selector shaft

and tighten the attachment nut to the

specified torque. See "Technical data".

V3 00 482

}

V3 00 481