Chery Tiggo 5 (T21). Manual - part 144

10–

22

10

Inspection

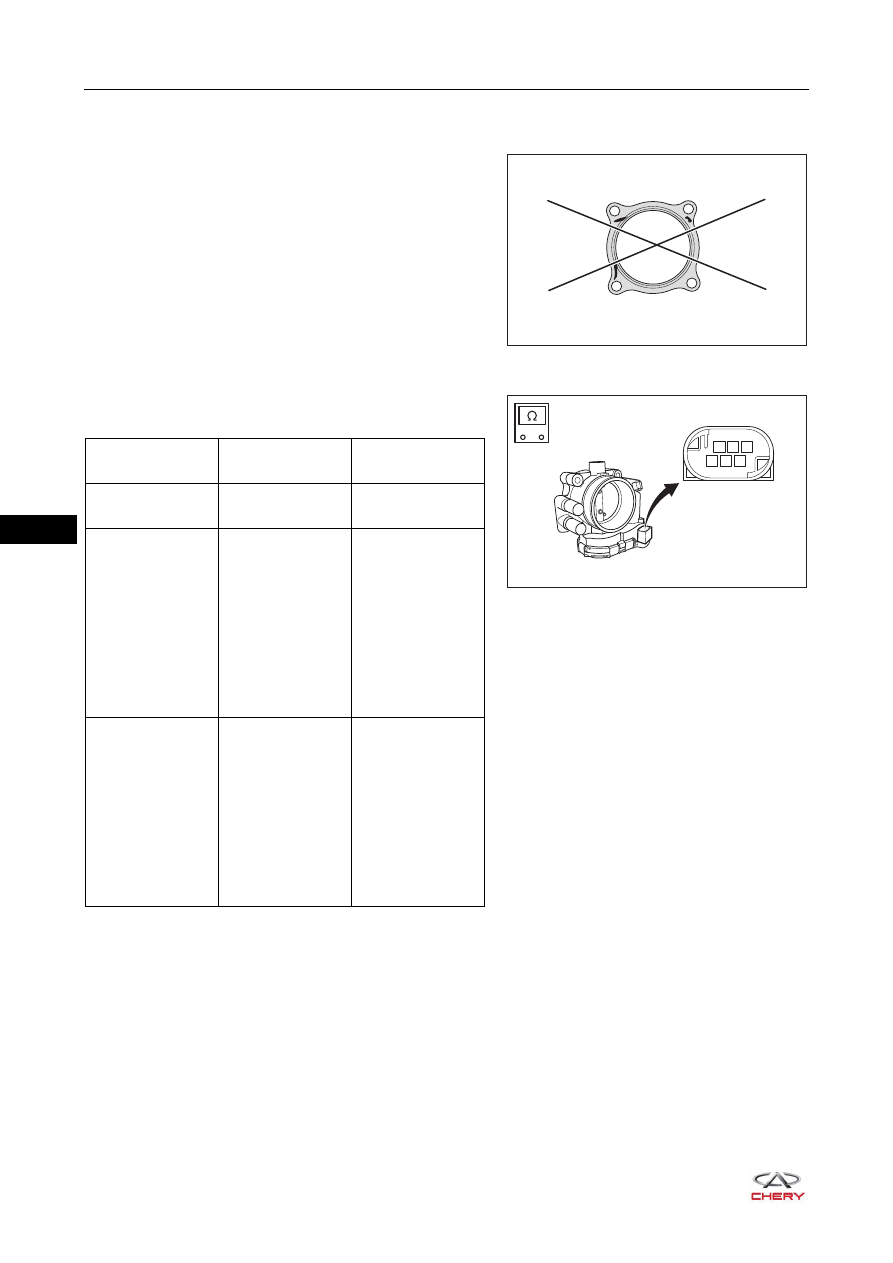

1. Check electronic throttle assembly gasket.

Check electronic throttle assembly gasket for worn or

bent. If there is worn or bent, replace electronic throttle

assembly gasket.

2. Check electronic throttle.

Measure electronic throttle resistance according to the

table below.

Cleaning

Cleaning tool

1. Thin stick: used to support throttle valve plate for cleaning the carbon deposited on contact wall between

valve plate and throttle. Please use plastic, wooden or bamboo thin stick. Do not use metal thin stick,

avoiding scratching or deforming the valve plate.

2. Clean cloth or paper towel

RT21100210

RT21100211

1

2

3

4

5

6

-

+

Tester

Connection

Adjustment

Specified

Condition

Terminal 3 -

Terminal 2

Normal

temperature

1.067 kΩ

Terminal 6 -

Terminal 2

Terminal 6 -

Terminal 3

Rotate throttle

Resistance

between terminal

6 and terminal 2

increases as

throttle opens;

resistance

between terminal

6 and terminal 3

decreases as

throttle opens.

Terminal 5 -

Terminal 2

Terminal 5 -

Terminal 3

Rotate throttle

Resistance

between terminal

5 and terminal 2

decreases as

throttle opens;

resistance

between terminal

5 and terminal 3

increases as

throttle opens.