Porshe 911 (997). Manual - part 19

Fit bearing cover for intermediate shaft with new sealing ring→ 152119 Removing and

installing bearing cover for intermediate shaft - section on "Installing" [997110 997111 997310

997311 997410 997411 997610 997611]→ 152119 Removing and installing bearing cover for

intermediate shaft - section on "Installing" [997120 997121 997320 997321 997430 997431

997620 997621].

2. Install guide rail for cylinder 4-6. Insert guide rail with slot into the crankcase. Fit screw with new

O-ring, grease the O-ring with Optimol MP3. → Tightening torque: 10 (7.5 ftlb.) Nm

3. Install tensioning rail for cylinder 4-6. Fit screw with new O-ring, grease the O-ring with Optimol MP3. →

Tightening torque: 10 (7.5 ftlb.) Nm

4. Remove auxiliary screw for gear carrier.

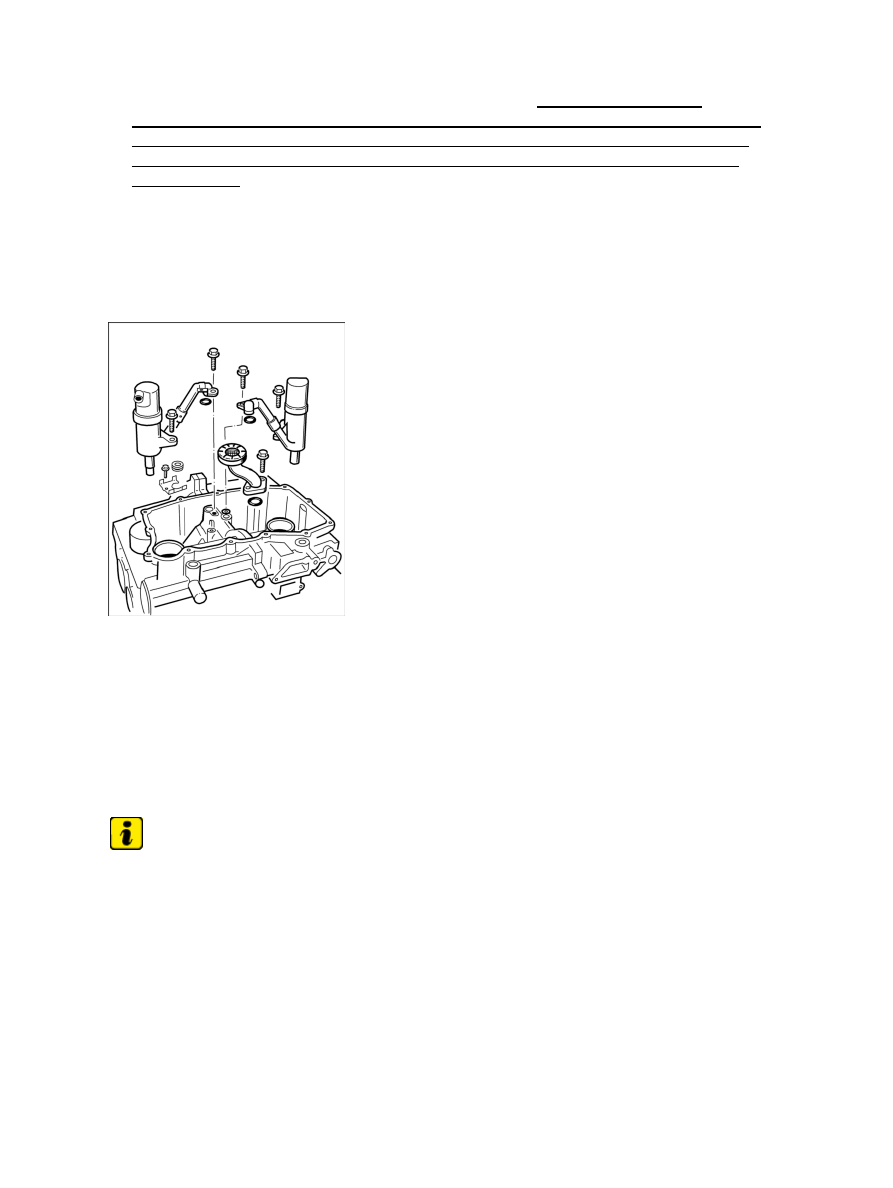

Components in the oil pan

5. Fit air/oil separator (swirl pots) and suction pipe. Replace two microencapsulated M6 x 20 Torx

screws and O-rings for the suction tube. → Tightening torque: 10 (7.5 ftlb.) Nm

6. Install oil pan. Apply a bead of sealant, Loctite 5900, to the cleaned and greased oil pan and secure

with 13 M6 x 20 Torx screws from the inside out. → Tightening torque: 10 (7.5 ftlb.) Nm

7. Fit oil filter, grease new O-ring with Optimol MP3. → Tightening torque: 25 (19 ftlb.) Nm

8. Fit thermostat with new seal. Tighten four M6 x 20 Torx screws. → Tightening torque: 10 (7.5 ftlb.) Nm

9. Fit tensioning rail for cylinder 1-3. Fit screw with new O-ring, grease the O-ring with Optimol MP3.

→ Tightening torque: 10 (7.5 ftlb.) Nm

Note

Replace O-rings for the oil pump and sealing rings for coolant guide housing.

•

10. Install water pump. Position water pump with the new seal (a single part in conjunction with the seal for

the oil pump housing). Position and tighten seven M6 Torx screws (two M6 x 30 screws on the dowel

sleeves, five M6 x 25 screws). → Tightening torque: 10 (7.5 ftlb.) Nm

Diagnostic system: reading out fault memory and activating systems

Assembling engine - from crankcase

233