Porshe 911 (997). Manual - part 18

→ The components have been run in in the fitting bores in the housing, therefore do not interchange them.

→ Pay attention to cleanliness.

57. Remove the flat-based tappets. Pull the components out with a strong magnet out of theflat-base tappets

housing. To avoid confusing the individual flat-based tappets, lay them on a labelled, clean surface (see

example) and cover.

58. Unscrew the top M6 guide rail screw (hexagon socket a/f 5) on cylinder 4-6.

59. Remove camshaft side 4-6 → 150520 Removing and installing camshaft - section on

"Removing" [997430 997431]→ 150520 Removing and installing camshaft - section on

"Removing" [997110 997111 997310 997311 997410 997411 997610 997611]→ 150520 Removing and

installing camshaft - section on "Removing" [997120 997121 997320 997321 997620 997621].

60. Remove flat-base tappet housing. Unscrew 11 M6 x 35 Torx screws per housing, one 1/4-inch E10 socket

is necessary for this. Take flat-base tappet housing out of the cylinder head. It is absolutely necessary to

replace O-rings for spark-plug recesses when installing.

61. Unscrew the top M6 guide rail screw (hexagon socket a/f 5) on cylinder 1-3.

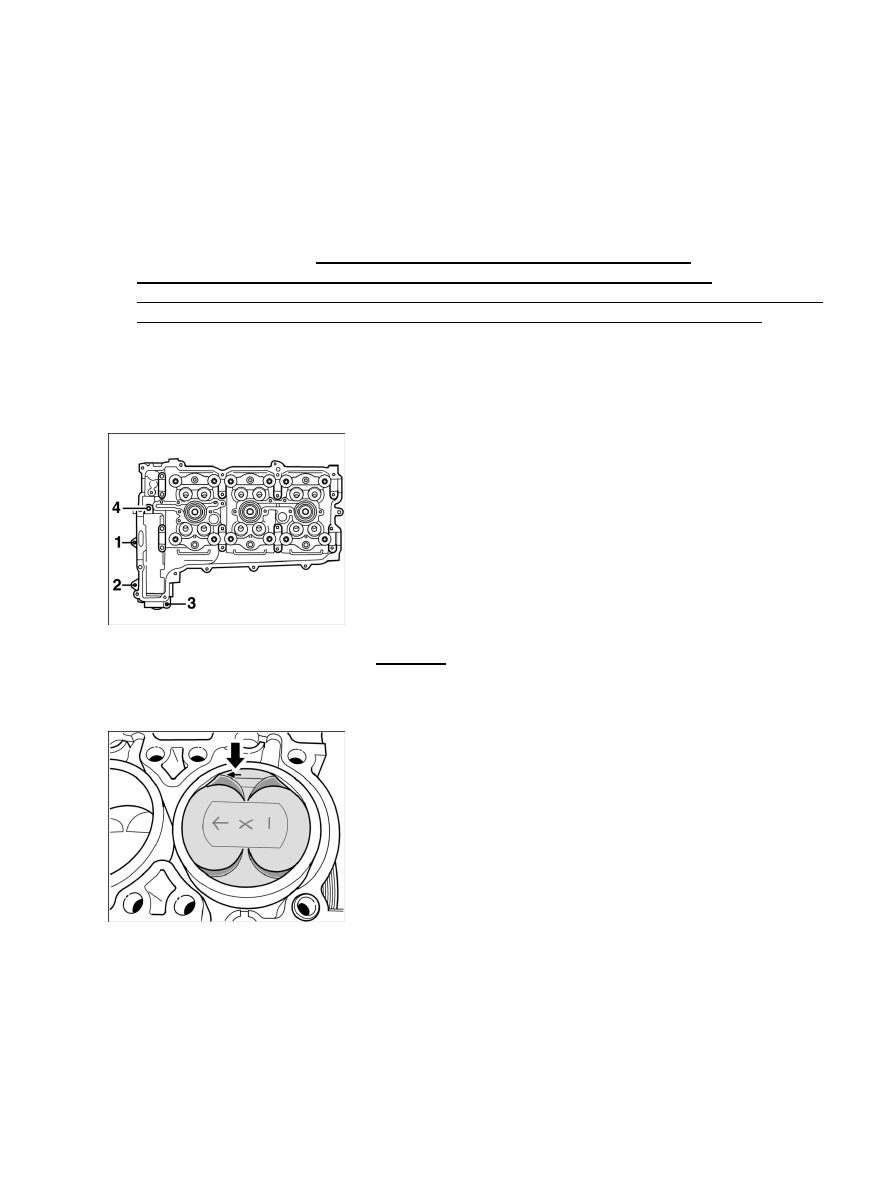

External cylinder head screwed connection

62. Unscrew four M6 x 30 Torx screws -Pos 1 - 4- per cylinder bank.

63. Remove cylinder head. Undo and unscrew 12 M10 x 230 Torx screws from inside to outside on

each cylinder head. Lift the cylinder header and seal off the crankcase.

Installation position of the pistons

64. Remove all carbon deposits and other residues on all six pistons with a brass brush, which will make the

engraved markings -Arrow facing flywheel side- visible. Before removing, number and mark the pistons

in the installation position.

65. Unscrew M27 aluminium screw plug for the assembly bore (piston pin).

66. Remove coolant closure cap (with connection for coolant ventilation). Unscrew six M6 x 20 inner

Torx screws, remove cover, and replace the seal.

67.

Diagnostic system: reading out fault memory and activating systems

Disassembling engine - up to crankcase

229