Porshe 911 (997). Manual - part 17

Servo pump

hexagon when doing this (a/f 27). Unscrew four Torx screws (3 M8 x 30 at the front -Arrows- , one M8

x 12 at the back), take the servo pump with line and supply tank out of the bracket.

Bracket for servo pump

30. Remove bracket for servo pump. Unscrew 4 M8 x 35 Torx screws, remove bracket.

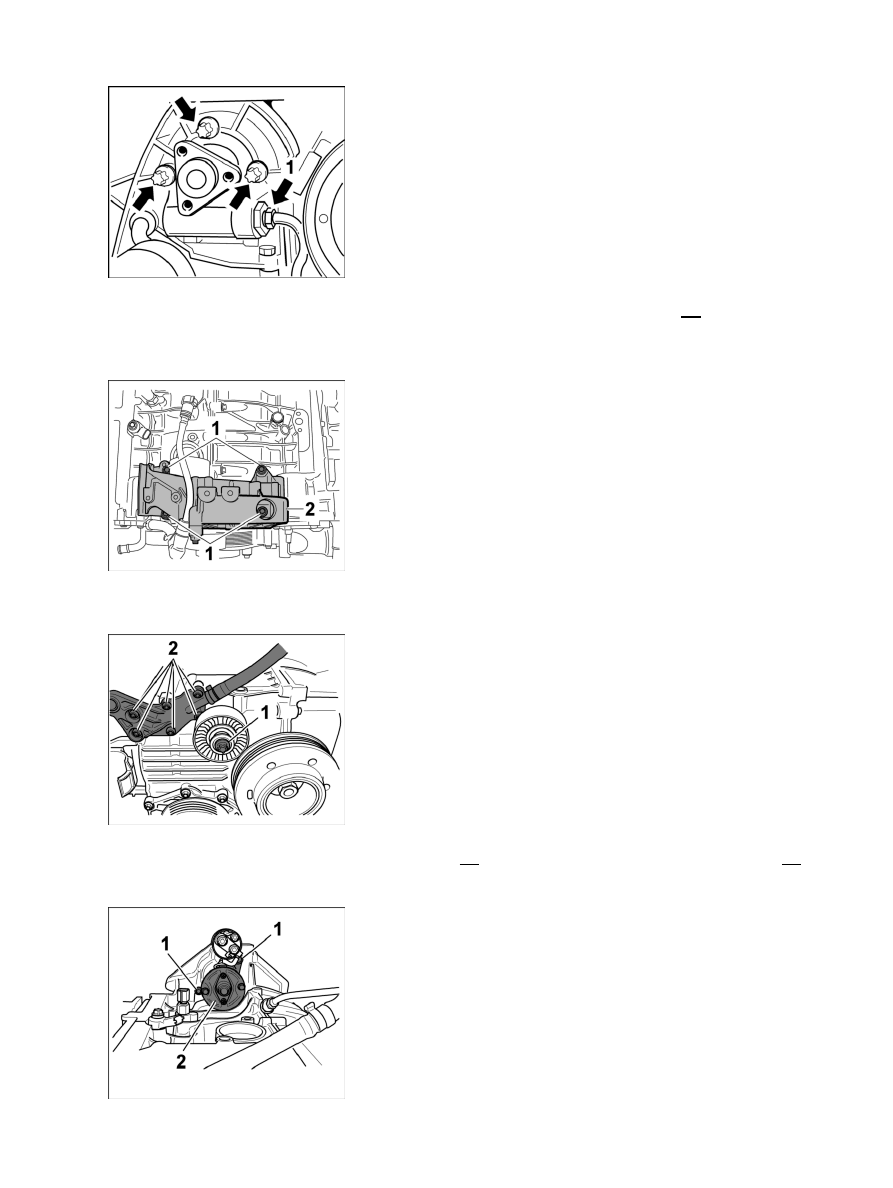

Deflection roller and closure cap for coolant

31. Remove one M8 x 60 screw for deflection roller -1- and six M6 x 20 Torx screws for closure cap -2- with

bleeder lines for coolant system.

Diagnostic system: reading out fault memory and activating systems

Disassembling engine - up to crankcase

225