Snowmobile Arctic Cat (2008 year). Manual - part 144

7-136

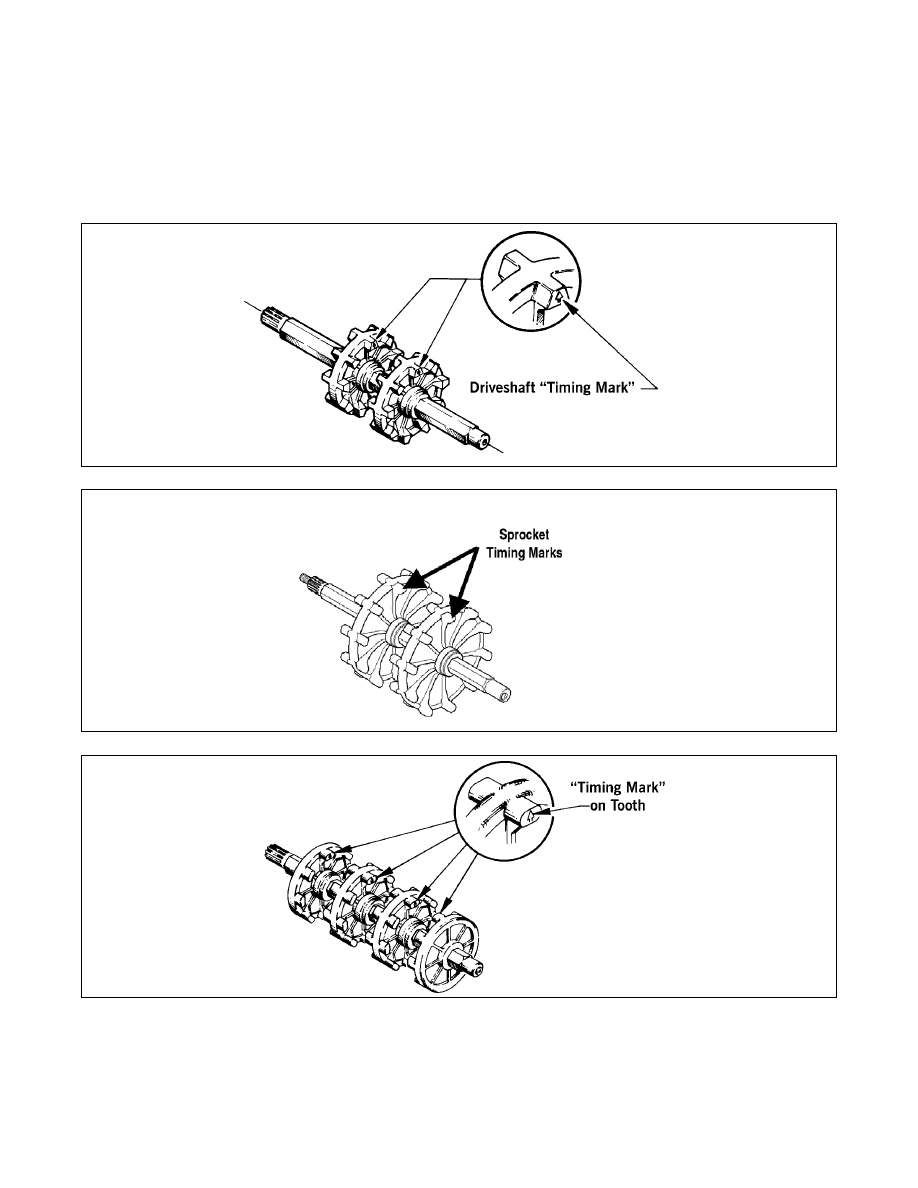

Drive Sprocket Locations

The following illustrations will provide all necessary

information to relocate sprockets on the driveshaft.

When information is required to assemble the drive-

shaft, refer to the parts manual for model being worked

on; then refer to the following illustrations using the

part number listed in the parts manual as a reference.

When pressing new sprockets on the driveshaft,

remember to align the sprocket alignment marks or the

sprockets won’t be timed correctly. See following

illustrations.

0728-351

737-870A

0727-829