Snowmobile Arctic Cat (2008 year). Manual - part 130

7-80

CM237

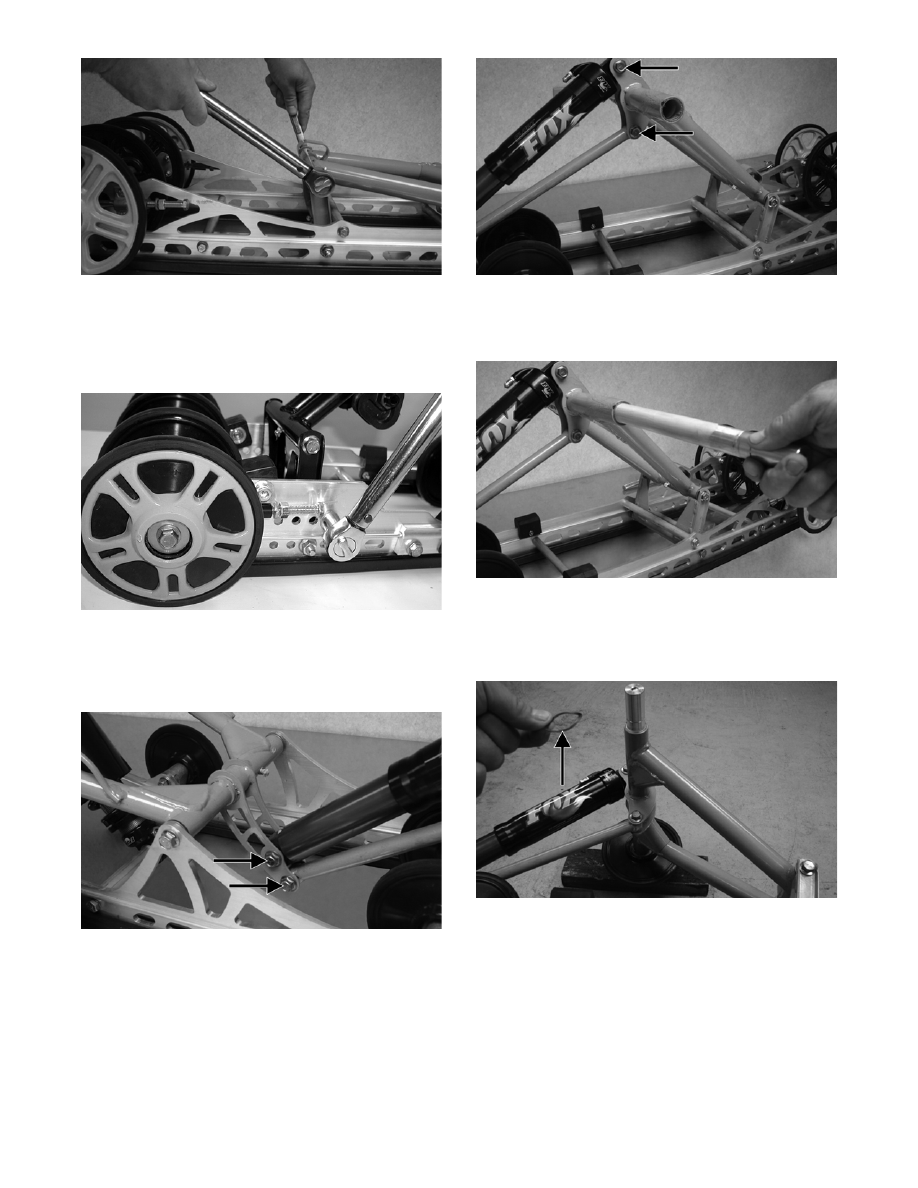

NOTE: If the rear arm limiter and rail support

were loosened (after step 4 of disassembling),

coat the threads of the cap screw with blue Loctite

#243 and tighten to 30 ft-lb.

MS158

3. With the sleeves installed, place the shock

absorber and shock link between the pivot arm

bracket. Secure with the cap screws and lock nuts.

Tighten securely.

CM233A

NOTE: Do not over-tighten the shock absorber

cap screw as the shock eyelet must be free to

pivot.

4. With the sleeves installed, position the shock link

in the appropriate holes of the idler arm brackets

and shock absorber; then insert the cap screw

through the eyelets. Secure with the cap screws

and lock nuts. Tighten securely.

CM234A

5. Install the inner carriage axle to the idler arm; then

install a wave washer and idler wheel. Secure with

the snap ring.

CM232

6. Turn the slide rail onto the side the idler wheel was

installed in (from step 5); then with a block of

wood placed under the inner carriage axle/idler

arm, install a wave washer.

CM238A

7. Install the remaining idler wheel along with the

snap ring onto the axle; then using a suitable driv-

ing tool, carefully drive the snap ring into the idler

wheel until it is properly seated in the groove of

the axle.