Snowmobile Arctic Cat (2008 year). Manual - part 129

7-76

CM230

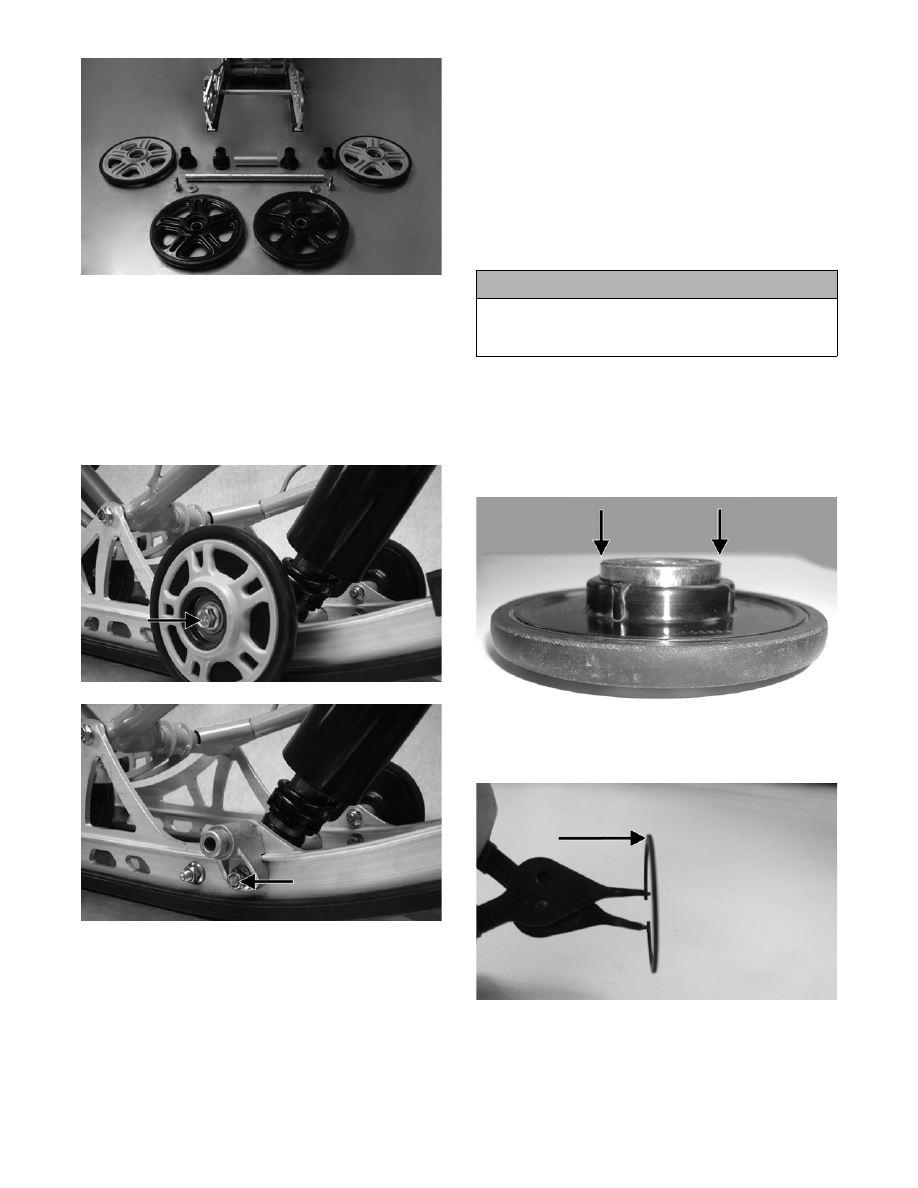

REMOVING SLIDE RAIL INNER

WHEELS

NOTE: The skid frame does not have to be

removed for this procedure.

1. Remove the cap screw and lock nut securing the

idler wheel and the idler wheel mounting block.

CM226A

CM227A

2. Account for the flat washer.

CLEANING AND INSPECTING

NOTE: Whenever a part is worn excessively,

cracked, or damaged in any way, replacement is

necessary.

1. Clean the bearings with a clean cloth.

2. Inspect all idler wheel inserts (inner and outer) for

any cracks.

3. Inspect the idler wheels for cracks, damage, or

poor bonding of the outer rubber portion.

4. Inspect the shaft for wear and damaged threads.

5. Inspect all idler wheel bearings. Turn each bearing

(by hand) and if any roughness or binding is noted,

replace the bearing.

6. If a bearing must be replaced, use this procedure.

A. Remove the bearing snap ring.

B. Using a suitable press or driving tool, remove

the bearing from the inside of the wheel.

C. Press the new bearing (on its outer race) into

the idler wheel.

MS006A

D. Install the snap ring making sure the “sharp

side” is directed away from the bearing.

MS007A

INSTALLING SLIDE RAIL IDLER

WHEELS

1. Secure the mounting block on the slide rail with a

cap screw and lock nut. Tighten to 34 ft-lb.

! CAUTION

Do not remove the bearing unless it is absolutely

necessary. The bearing will be damaged during

removal.