Snowmobile Arctic Cat (2008 year). Manual - part 102

6-52

ZJ196

ZJ197

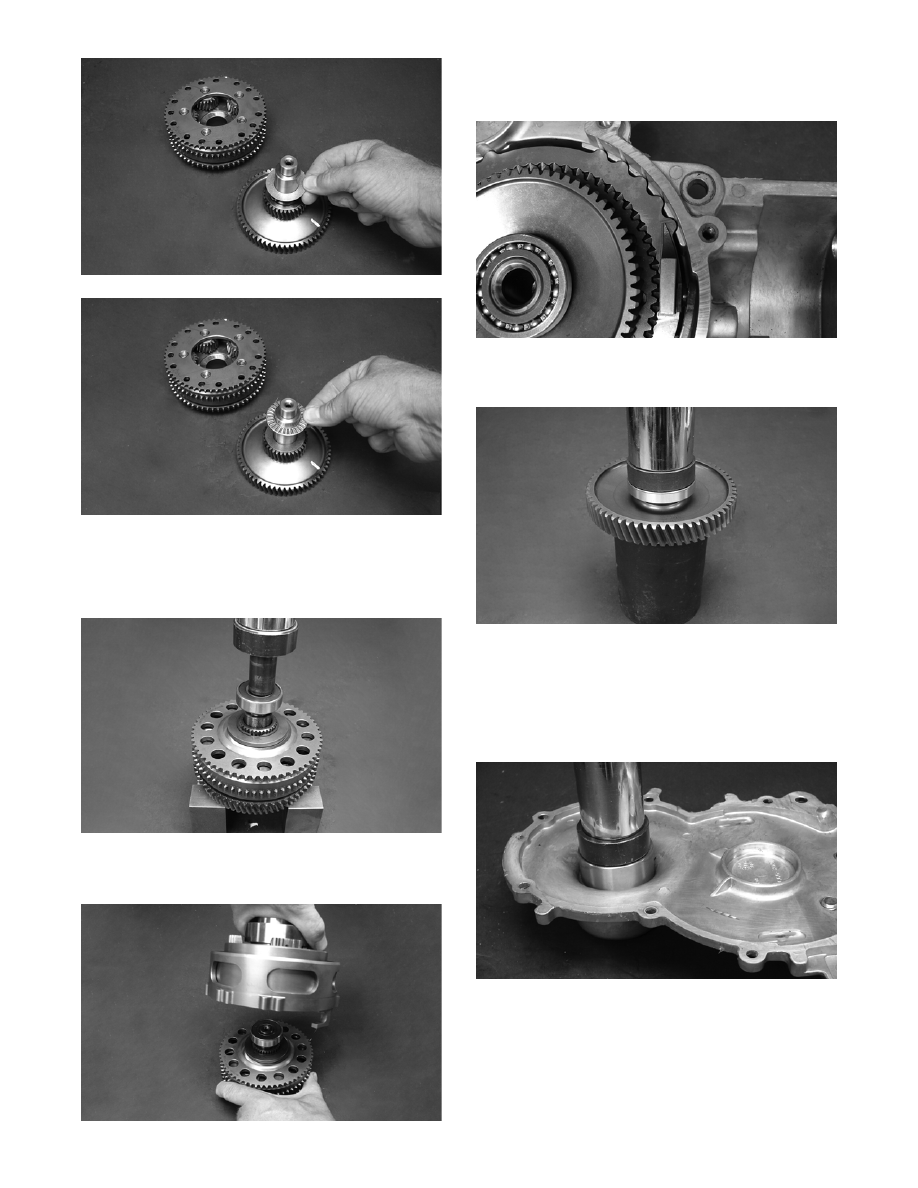

5. Position the planetary gear assembly onto the

transfer gear shaft; then install the spacer washer.

Using a suitable press, install the inner bearing

onto the transfer gear shaft.

ZJ208

6. Install the output gear assembly into the slider

assembly until the inner bearing is properly seated.

ZJ194

7. With the alignment notches of the slider and gear

case properly positioned, install the slider/output

gear assembly into the gear case.

ZJ201

8. Using a suitable bearing press, install the outer

bearing onto the transfer gear shaft.

ZJ199

9. Using a suitable bearing press and fixture, install

the input shaft bearing to the gear case; then install

the oil seal.

NOTE: A light coat of grease must be applied to

the seal prior to installing.

ZJ202