Snowmobile Arctic Cat (2008 year). Manual - part 101

6-48

ZJ195

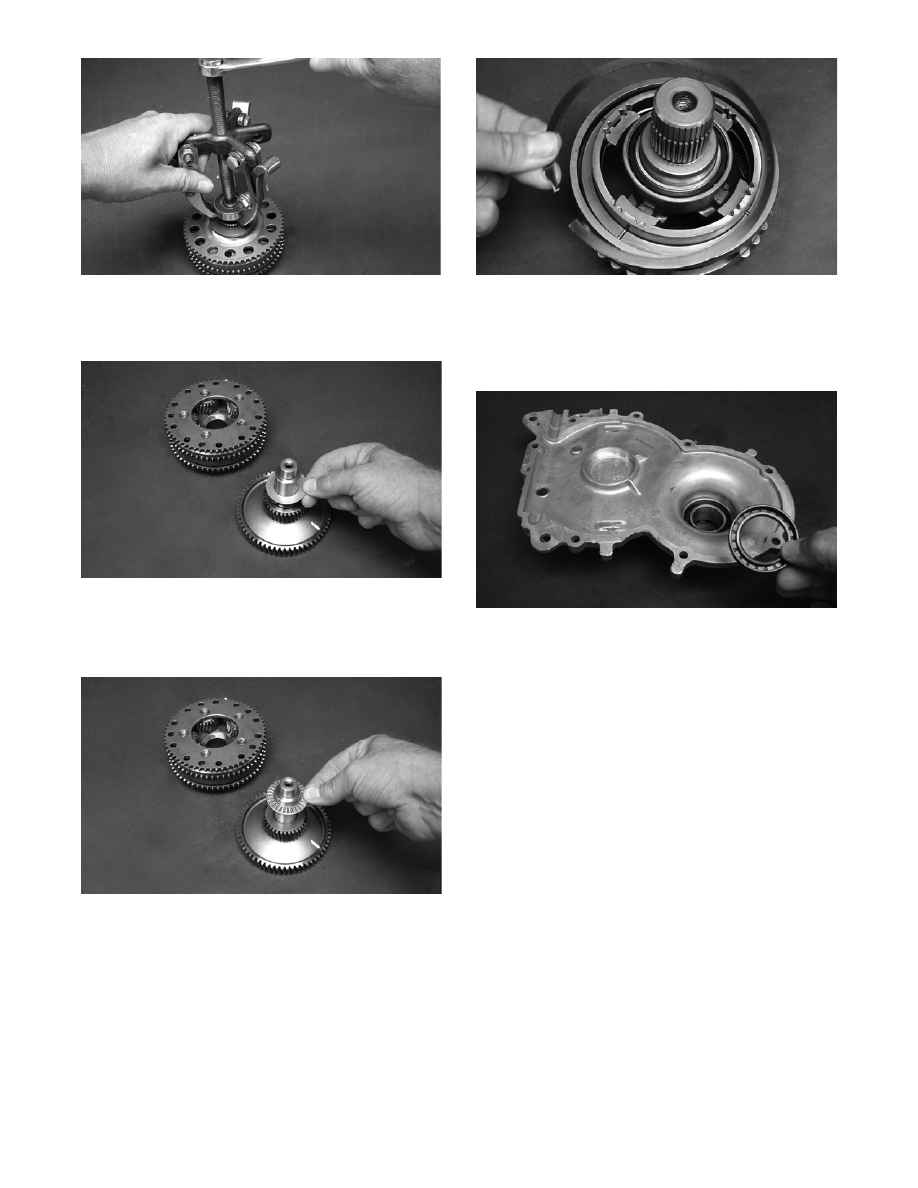

12. Remove the transfer gear from the planetary gear

assembly and account for the thrust washer and

thrust bearing.

ZJ196

NOTE: For assembling purposes, note that the

thrust bearing is positioned between the thrust

washer and the gear assembly.

ZJ197

13. Remove the retaining ring and thrust washer

securing the slider housing assembly to the output

shaft assembly.

ZJ200

14. Using a suitable puller, remove the bearing from

the output shaft.

15. Using a suitable seal removing tool, remove the

input/output shaft seals from the gear case.

ZJ204

CLEANING AND INSPECTING GEAR

CASE

NOTE: Whenever a part is worn excessively,

cracked, or damaged in any way, replacement is

necessary.

NOTE: The planetary gear assembly is a non-ser-

viceable component. If any damage or wear is

detected, it must be replaced.

1. Wash the gear case halves in parts-cleaning sol-

vent.

2. Inspect the gear case halves for scoring, pitting,

scuffing, or any imperfections in the casting.

3. Inspect all threaded areas for damaged or stripped

threads.

4. Inspect the bearing areas for cracks or excessive

bearing movement. If evidence of excessive bear-

ing movement is noted, replace the component.

5. Inspect the sealing surfaces of the gear case halves

for trueness.

6. Wash the unsealed gear case bearings in parts-

cleaning solvent.