Snowmobile Arctic Cat (2008 year). Manual - part 97

6-32

ZJ250A

15. Install the drive belt.

NOTE: For installing drive belt, see Removing/

Installing Drive Belt (ACT Roller Driven Pulley) in

this section.

16. Place the access panels into position and secure

with existing hardware.

17. Check the track for alignment and recommended

tension; then tighten the cap screws securely (see

Section 7).

DISASSEMBLING GEAR CASE

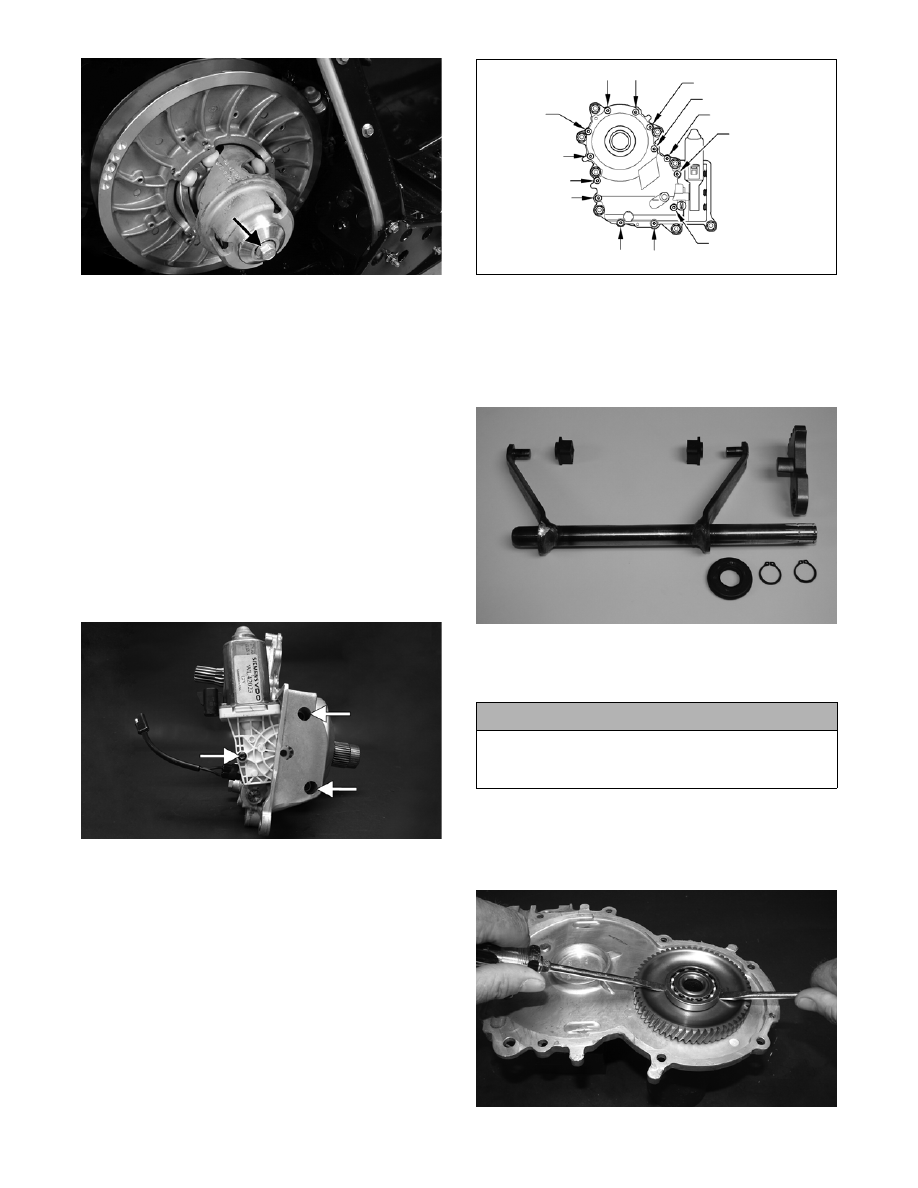

1. On electronic reverse models, remove the three

torx-head cap screws securing the shift actuator to

the gear case and remove the actuator; then

remove the gear indicator switch.

ZJ186A

2. Remove the torx-head cap screws securing the

gear case cover to the gear case assembly; then

insert two flat-blade screwdrivers into the slots on

the gear case. Working back and forth, pry the

cover up and off the gear case.

742-195B

3. Drain the gear case fluid into a suitable container.

4. Remove the shift fork assembly; then remove the

retaining ring securing the shift fork arm to the

shaft and remove the arm. Account for the retain-

ing rings, O-ring, and slider blocks.

ZJ300

NOTE: For assembling purposes, note the posi-

tion of the slider blocks on the shift fork arm.

5. Secure the gear case cover in a suitable clamping

device; then using two flat-blade screwdrivers

from opposite sides of the cover bearing, evenly

pry the input shaft bearing up and off the shaft.

ZJ189

! CAUTION

If the input shaft bearing is removed, always replace

it with a new one or severe component damage may

occur.