Snowmobile Arctic Cat (2008 year). Manual - part 98

6-36

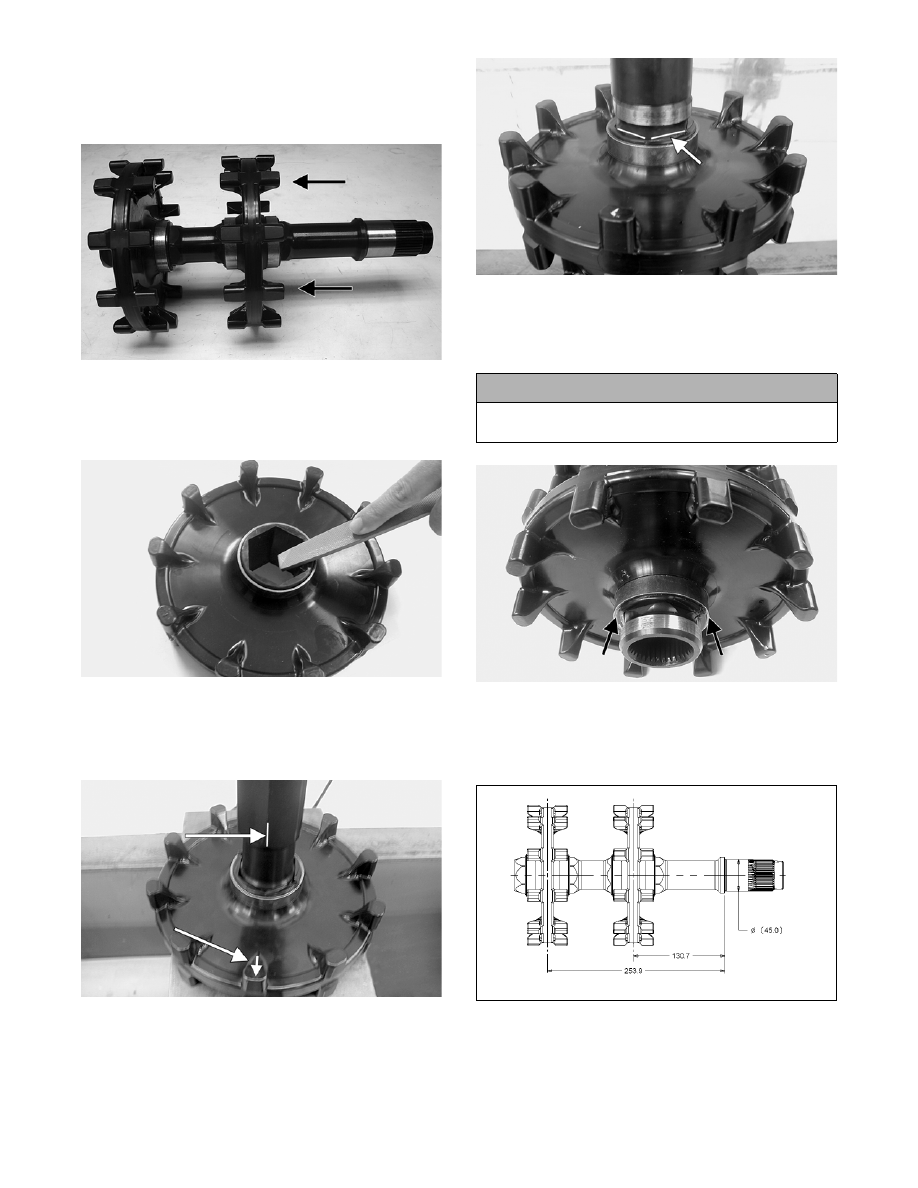

INSTALLING DRIVE SPROCKETS

NOTE: The drive sprockets must be installed on

the gear case end of the driveshaft.

ZJ216A

NOTE: Prior to installing the sprockets onto the

driveshaft, it is advisable to lightly chamfer the

inside edge of the sprocket to avoid binding.

MS362

1. Properly align the scribed line on the driveshaft

(from removing) with the timing arrow on the

drive sprocket; then slide the sprocket onto the

driveshaft as far as it will go.

MS360A

2. Using a suitable press and fixture, press the drive-

shaft into the sprocket until it aligns with the line

scribed in removing.

MS361A

3. Slide the remaining sprocket onto the driveshaft

making sure the timing arrow/lines (from remov-

ing) are aligned; then using the press/fixture, press

the sprocket to the remaining alignment line.

MS359A

4. Using a calipers, measure distances between the

sprockets and from the sprockets to each end of

the driveshaft for proper location (see illustra-

tions).

0742-042

! CAUTION

Always press against the tension-collar of the drive

sprockets or damage to the components will occur.