Snowmobile Arctic Cat (2008 year). Manual - part 95

6-24

AF090

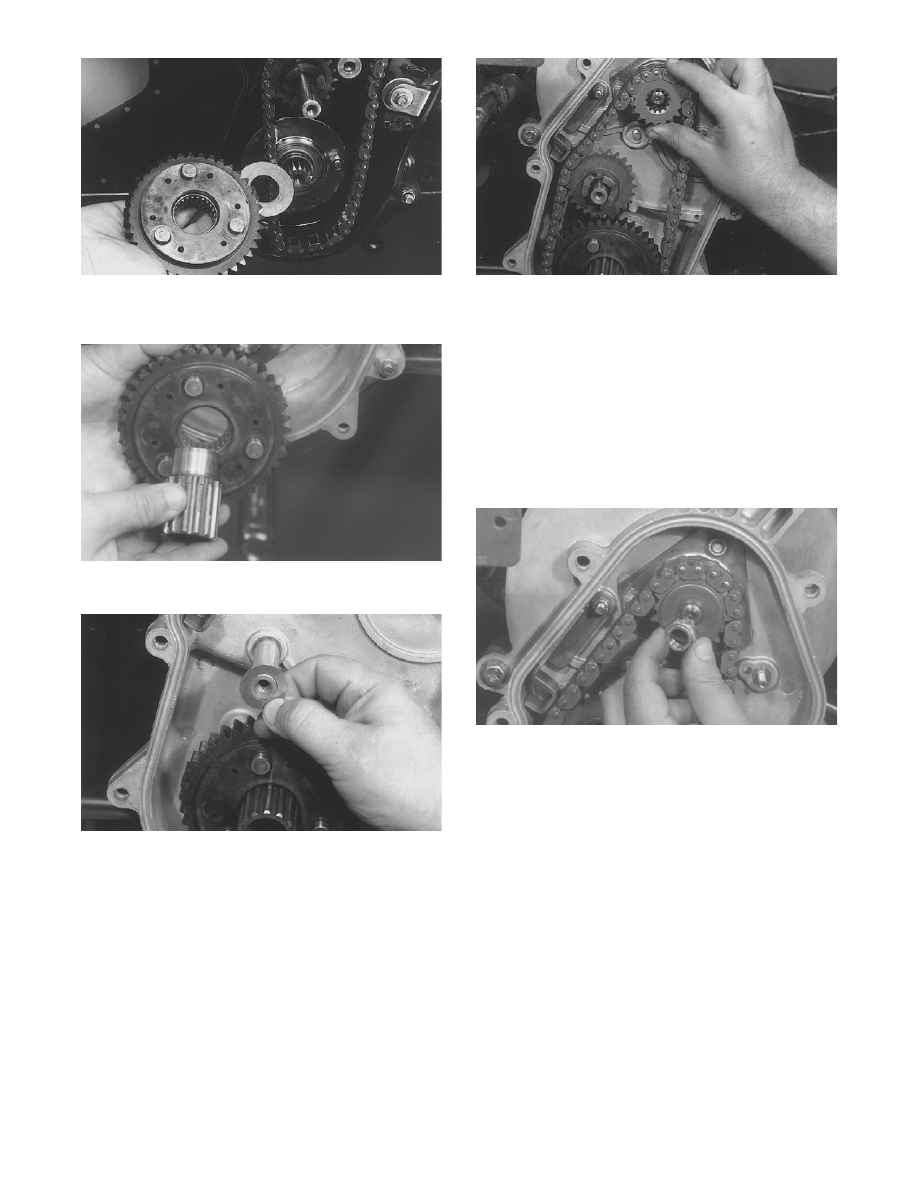

12. Install the bottom sprocket and driveshaft exten-

sion.

AF427

13. Position one shim washer on the idler gear shaft.

AF430

14. Position the chain around the lower reverse

sprocket; then place the idler sprocket and top

sprocket into the chain. Slide sprockets into posi-

tion on the idler shaft and driven shaft.

AF441

NOTE: If the chain tension is too tight to allow

installation of the top sprocket, remove the PTO-

side driven shaft bearing. This will allow the driven

shaft to be lifted at the PTO-side and will allow the

sprocket to slide onto the splined end of the driven

shaft.

15. Secure the top sprocket with a spring washer (with

the high side directed away from the sprocket) and

lock nut (coated with green Loctite #609). Tighten

the lock nut to 35 ft-lb.

AF432

NOTE: If the PTO-side driven shaft bearing was

removed to make the sprocket installation easier,

install the bearing and flange plate. Lock the bear-

ing collar by driving it in the direction of rotation to

lock the collar to the bearing and shaft. Tighten the

collar set screw.

16. Place the rubber alignment pin into position in the

idler sprocket; then slide the outer idler gear on the

shaft. Install shim washer on the shaft.