Snowmobile Arctic Cat (2008 year). Manual - part 94

6-20

AF436

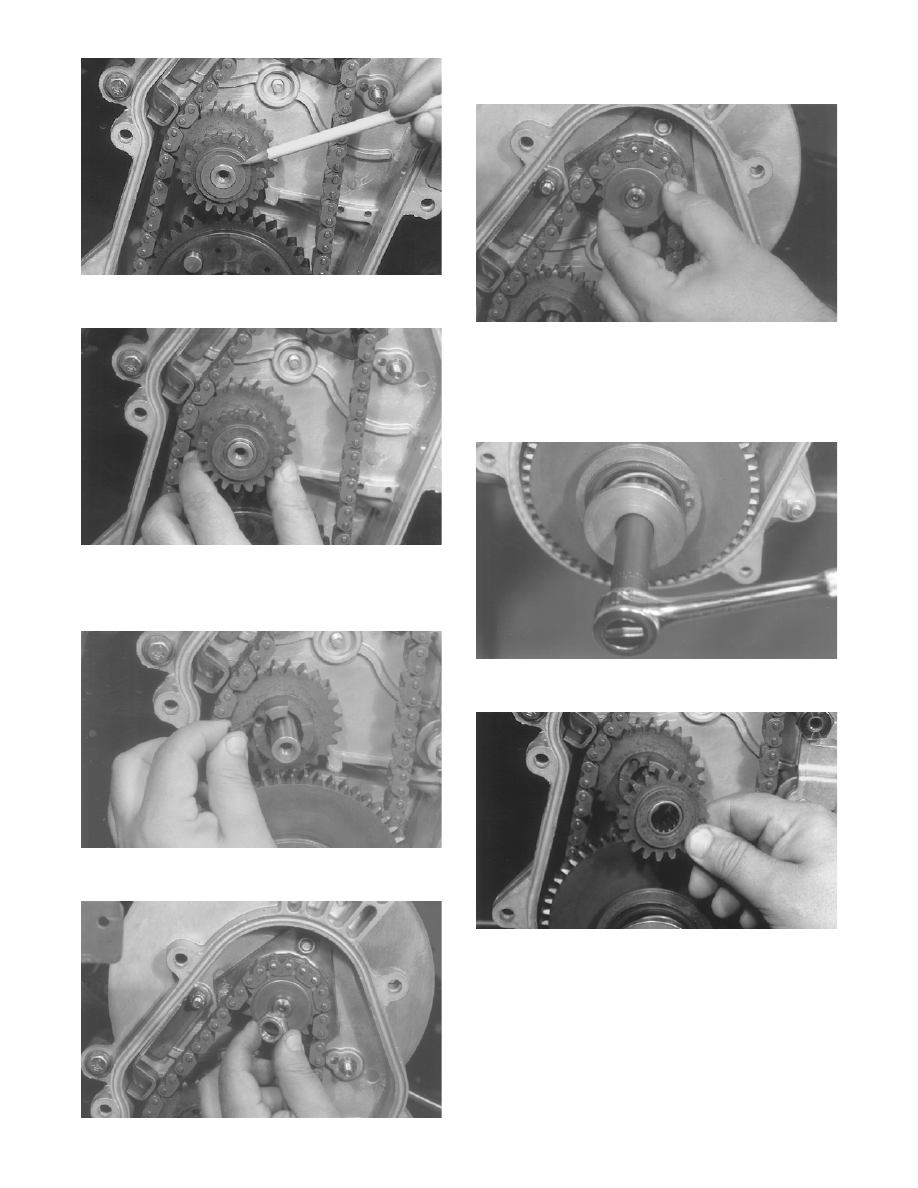

10. Remove the outer idler sprocket from the shaft.

AF437

11. Slide the small rubber alignment pin from the face

of the inner idler sprocket and place in safe loca-

tion until assembly.

AF439

12. Remove the lock nut securing the top sprocket.

AF432

13. Remove the spring washer in front of the top

sprocket.

AF444

14. Set the brake lever lock. Remove the cap screw

and large washer securing the bottom sprocket.

NOTE: The bottom sprocket cap screw and

washer are spring loaded.

AF428

15. Remove the reverse gear.

AF442

16. Remove the top sprocket, chain, and idler gear.

Account for one shim washer located behind the

idler gear.