Snowmobile Arctic Cat (2008 year). Manual - part 92

6-12

4. Using a stiff ruler centered between the drive

clutch and driven pulley, push down on the drive

belt just enough to remove all slack. Note the

amount of deflection on the ruler at the bottom of

the straightedge. The deflection should be within

the range of 25-31 mm (1-1 1/4 in.).

NOTE: Push down on the belt with the ruler only

until the bottom of the belt flexes upward; then

read the amount of deflection.

5. To correct drive belt deflection, washers can be

removed or added between the stationary and

movable sheaves of the driven pulley.

NOTE: If the drive belt deflection is above specifi-

cations, the snowmobile will bog and lack power at

clutch engagement. For good performance, proper

belt deflection is critical.

6. Secure the belt guard.

ACT Roller Driven Pulley

(Crossfire/F-Series/M-Series)

REMOVING

1. Remove the drive belt.

NOTE: For removing drive belt, see Removing/

Installing Drive Belt (ACT Roller Driven Pulley) in

this section.

2. Using a 9/16-in. socket and extension, remove the

cap screw securing the driven pulley to the driven

shaft.

3. Slide the driven pulley off the driven shaft.

NOTE: Account for and remove any alignment

washers. These washers must be used during

installing.

DISASSEMBLING

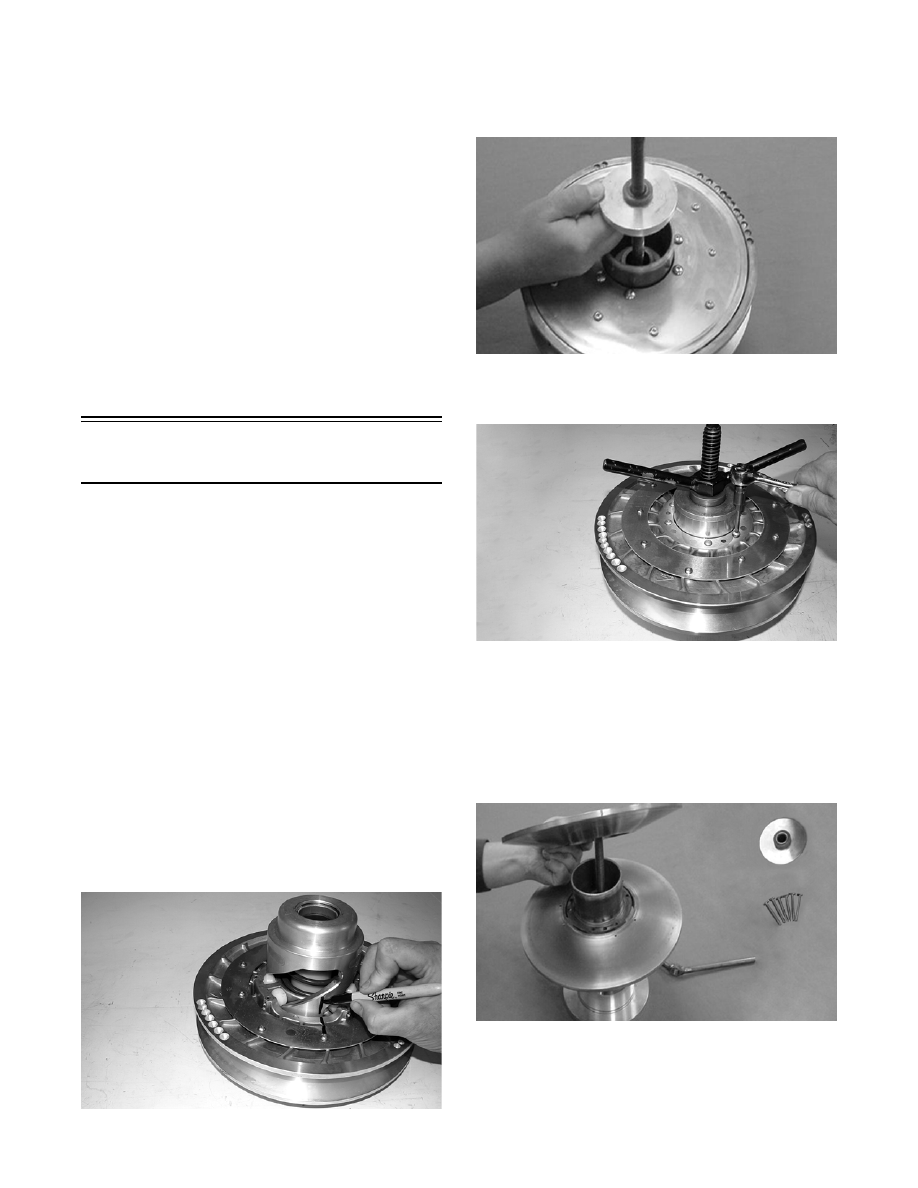

1. Prior to disassembling, mark the driven pulley

sheaves and torque bracket.

CM060

2. Place the driven pulley on the Driven Pulley Com-

pressor; then install the compressor flange spacer

and wing nut and compress the driven pulley

spring.

FS090

3. Remove the torx-head cap screws securing the

movable sheave to the pulley.

CM061

NOTE: To loosen the torx-head cap screws, it

may be necessary to insert a torx-bit and strike

each screw with a hammer.

4. Release the compression of the spring by remov-

ing the wing nut; then remove the movable sheave.

Account for the spacer (retainer).

FS093