Snowmobile Arctic Cat (2008 year). Manual - part 90

6-4

739-040A

3. Secure the cam arm pins with new lock nuts and

tighten to 19 in.-lb.

4. Place the spring and cover into position making

sure the timing mark on the cover is properly

aligned; then compress the spring and install the

machine screws coated with blue Loctite #243 and

lock washers. In a crisscross pattern, tighten

evenly to 10 ft-lb.

MS402A

FC091

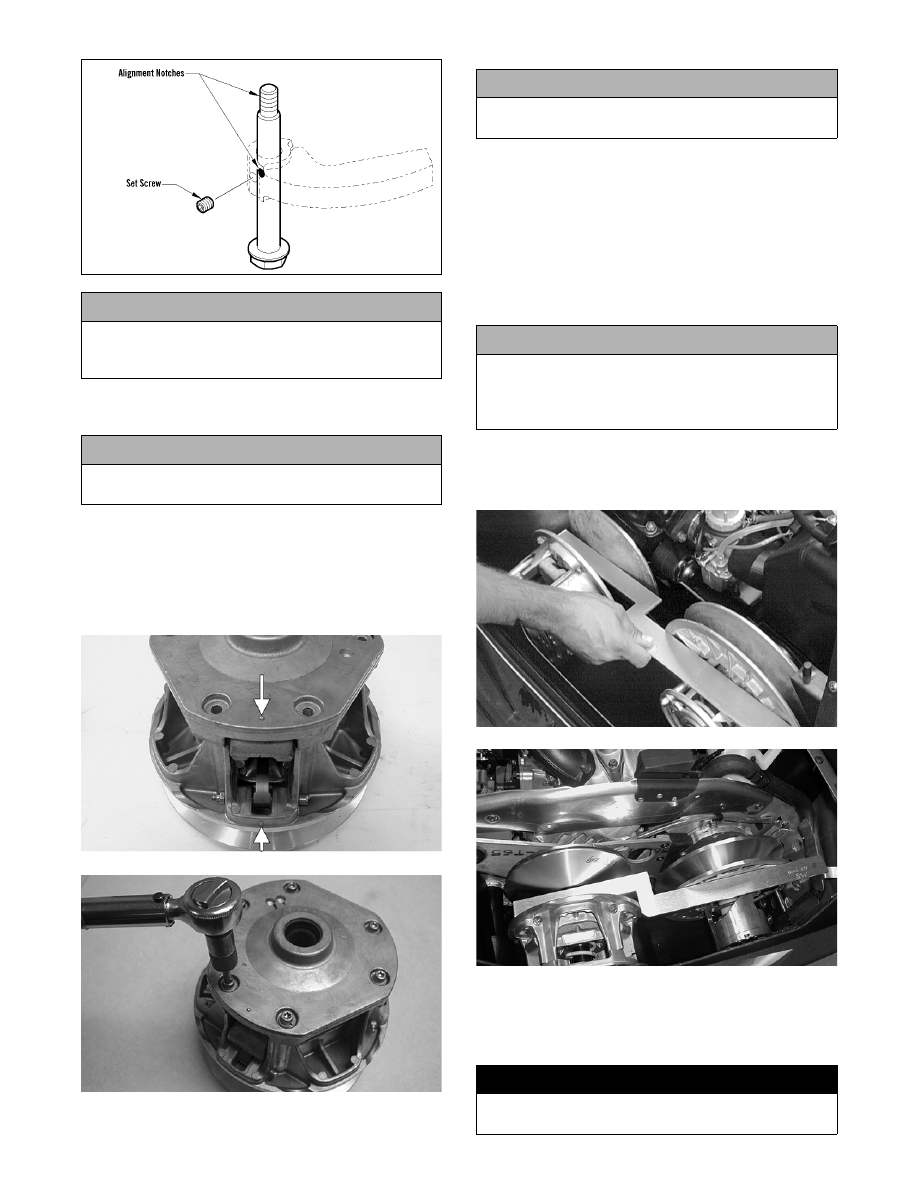

Installing

NOTE: Before installing the drive clutch, be sure

to wipe both the crankshaft taper and clutch

mounting taper clean using a clean towel.

1. Place the drive clutch into position on the crank-

shaft and secure with the appropriate cap screw

and lock washer. Tighten to 55 ft lb.

2. Check alignment between the drive clutch and

driven pulley (see appropriate Drive Clutch/

Driven Pulley in this section).

AF468D

MS390

3. Install the drive belt. Check drive belt deflection

(see appropriate Drive Clutch/Driven Pulley in

this section). Secure the belt guard and install the

plug in the belly pan.

! CAUTION

It is critical that green Loctite #620 be applied to the

set screw holes in the cam arms or component dam-

age may occur.

! CAUTION

When installing cam arms, always use new lock nuts

and cam arm set screws.

! CAUTION

Care must be taken when installing the cover not to

damage the bushing.

! CAUTION

When installing the drive clutch, do not tighten the

cap screw with any kind of impact tool. Tighten cap

screw using a hand torque wrench only. Failure to

do so could result in stationary sheave damage.

! WARNING

Never operate the engine without the belt guard/side

panel secured.