Snowmobile Arctic Cat (2008 year). Manual - part 88

5

5-33

CM110A

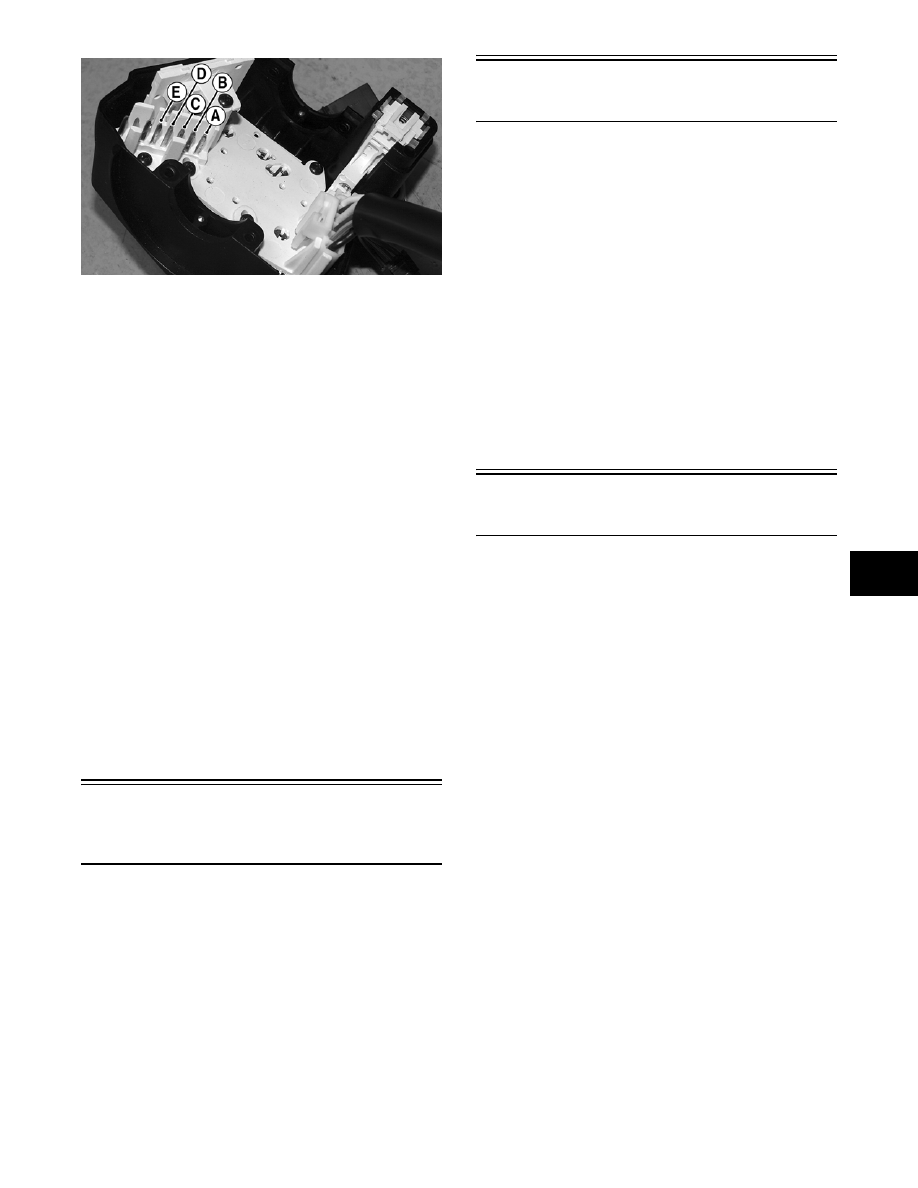

5. With the thumb warmer toggle in the high posi-

tion, connect one ohmmeter lead to pin (C) and the

other ohmmeter lead to pin (A). The meter must

read 1 ohm or less resistance.

NOTE: If either test does not read within specifi-

cation, replace the complete control assembly.

6. With the handwarmer toggle in the low position,

connect one ohmmeter lead to pin (C) and the

other ohmmeter lead to pin (D). The meter must

read 1 ohm or less resistance.

7. With the handwarmer toggle in the high position,

connect one ohmmeter lead to pin (C) and the

other ohmmeter lead to pin (E). The meter must

read 1 ohm or less resistance.

NOTE: If either test does not read within specifi-

cation, replace the complete control assembly.

INSTALLING

1. Connect the handlebar/thumb warmer harness to

the switch; then place the control assembly on the

handlebar.

2. Secure with the four screws; then install the han-

dlebar pad.

Testing Thumb

Warmer Switch

(Bearcat 570/Panther 370)

1. Remove the handlebar pad.

2. Disconnect the thumb warmer two-wire connector.

3. In the switch connector, connect one ohmmeter

lead to each terminal.

4. With the switch in the OFF position, the meter

must read an open circuit. With the switch in the

ON position, the meter must read 1 ohm or less

resistance.

5. Connect the leads; then install and secure the han-

dlebar pad.

Testing Passenger

Handwarmer Switch

1. Disconnect the lead wires from the switch.

2. With the switch in the LO position, connect one

ohmmeter lead to the green/white wire at the con-

nector; then connect the other ohmmeter lead to

the brown wire at the connector. The meter must

read less than 1 ohm of resistance.

3. With the switch in the MED position, connect one

ohmmeter lead to the green/red wire at the connec-

tor; then connect the other ohmmeter lead to the

brown wire at the connector. The meter must read

less than 1 ohm of resistance.

4. With the switch in the HI position, connect one

ohmmeter lead to the green/blue wire at the con-

nector; then connect the other ohmmeter lead to

the brown wire at the connector. The meter must

read less than 1 ohm of resistance.

Testing Passenger

Handwarmer Elements

NOTE: During this test, resistance will vary due

to temperature; therefore, this test should be made

at room temperature of 20° C (68° F).

1. Disconnect the lead wires from the main wiring

harness.

2. For the LO position, connect one ohmmeter lead

to the green/white wire from the element; then

connect the other ohmmeter lead to the green wire

from the element. The meter must read between

23.8-32.2 ohms.

3. For the MED position, connect one ohmmeter lead

to the green/red wire from the element; then con-

nect the other ohmmeter lead to the green wire

from the element. The meter must read between

13.6-18.4 ohms.

4. For the HI position, connect one ohmmeter lead to

the green/blue wire from the element; then connect

the other ohmmeter lead to the green wire from the

element. The meter must read between 8.7-11.7

ohms.