Snowmobile Arctic Cat (2008 year). Manual - part 31

2-61

2

NOTE: Check to be sure the mark on the control

arm is aligned with alignment mark on the oil-

injection pump boss in the full-open position. If the

marks are not aligned, adjust synchronization by

loosening the jam nuts on the adjuster. Rotate the

jam nuts/adjuster nut until proper alignment is

attained. Tighten jam nuts.

NOTE: When the cable/linkage adjusting nut is

adjusted correctly, the throttle lever will move

approximately 1/8 in. before the oil-injection pump

arm begins to move.

6. Remove the oil bleed plug from the oil injection

pump. When oil flows from pump free of air bub-

bles and the hose is full of oil, install the oil bleed

plug and tighten.

NOTE: It is advisable to place a cloth beneath the

oil-injection pump to contain any oil spilled during

the bleeding process.

7. With the throttle cable and fuel lines properly

routed, install the flange clamps to the intake

flanges; then install the carburetors and secure

with the clamps.

FZ006

8. Install the headlight support bracket and secure the

bracket with the cap screws and lock nuts.

NOTE: The headlight support bracket must be

installed before the engine is secured.

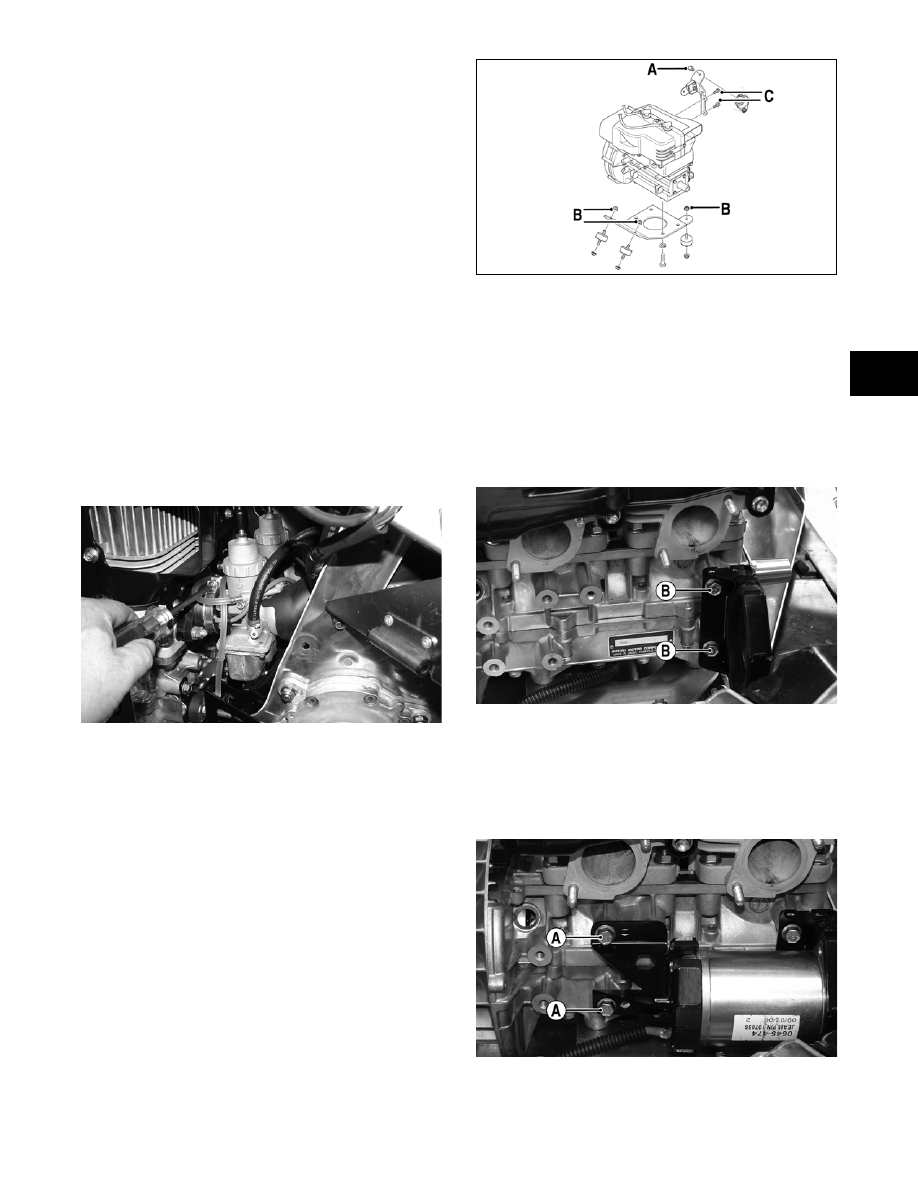

9. Install the rear MAG-side engine mounting

bracket to the engine with the two cap screws (C).

Tighten to 20 ft-lb; then position the engine to the

chassis mounts.

0742-672A

10. Install the three lock nuts (B) securing the engine

plate to the chassis; then install the cap screw (A)

securing the rear MAG-side engine bracket to the

chassis. Tighten to 20 ft-lb.

11. Carefully work the carburetor boots over the

intake bore of the carburetors.

12. Install the PTO-side starter motor bracket to the

engine and secure with the two cap screws (B).

Tighten to 20 ft-lb.

FZ023A

13. With the rubber dampers in place on the brackets,

install the starter motor and the MAG-side bracket

to the engine with the two cap screws (A) and

tighten to 20 ft-lb. Route the ground cable up

through the engine plate and secure with cap

screw. Tighten securely.

FZ024A

14. Apply a thin coat of high-temperature silicone

sealant to each exhaust port; then install the

exhaust gaskets.