Snowmobile Arctic Cat (2008 year). Manual - part 30

2-57

2

MS384

MS384

0738-291

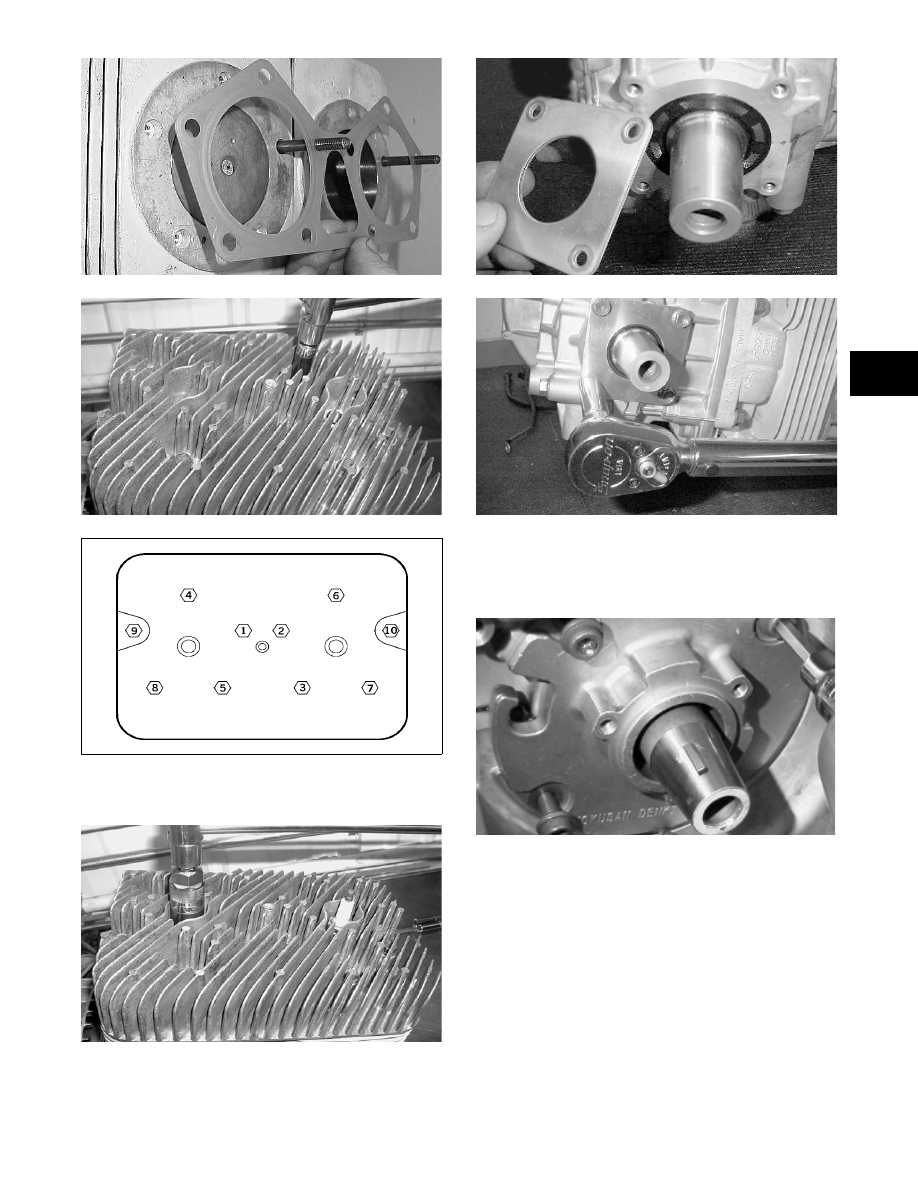

15. Install the spark plugs; then tighten to 19 ft-lb.

Pressure test the engine (see Section 3).

MS385

16. Position the seal retainer plate on the PTO-side;

then install the four cap screws. Tighten the cap

screws to 8 ft-lb.

MD0253

MD0292

17. Install the stator plate so the ignition wire cut-out

is in the upper left position. Lightly coat the four

Allen-head cap screws with red Loctite #271; then

install and tighten them to 8 ft-lb.

MD0255

18. Place the stator wiring through the hole in the

crankcase; then install the stator. Lightly coat the

three Allen-head cap screws with red Loctite

#271; then tighten them to 8 ft-lb.