Snowmobile Arctic Cat (2008 year). Manual - part 29

2-53

2

2. Insert a snap gauge into each piston-pin bore; then

remove the gauge and measure it with a microme-

ter. The diameter measurement must be within

18.002-18.010 mm (0.7087-0.7090 in.). Take two

measurements to ensure accuracy.

AC092

CONNECTING-ROD SMALL END

BORE

1. Insert a snap gauge into each connecting-rod small

end bore; then remove the gauge and measure it

with a micrometer.

AN061

2. The diameter measurement must be within

23.003-23.011 mm (0.9056-0.9059 in.).

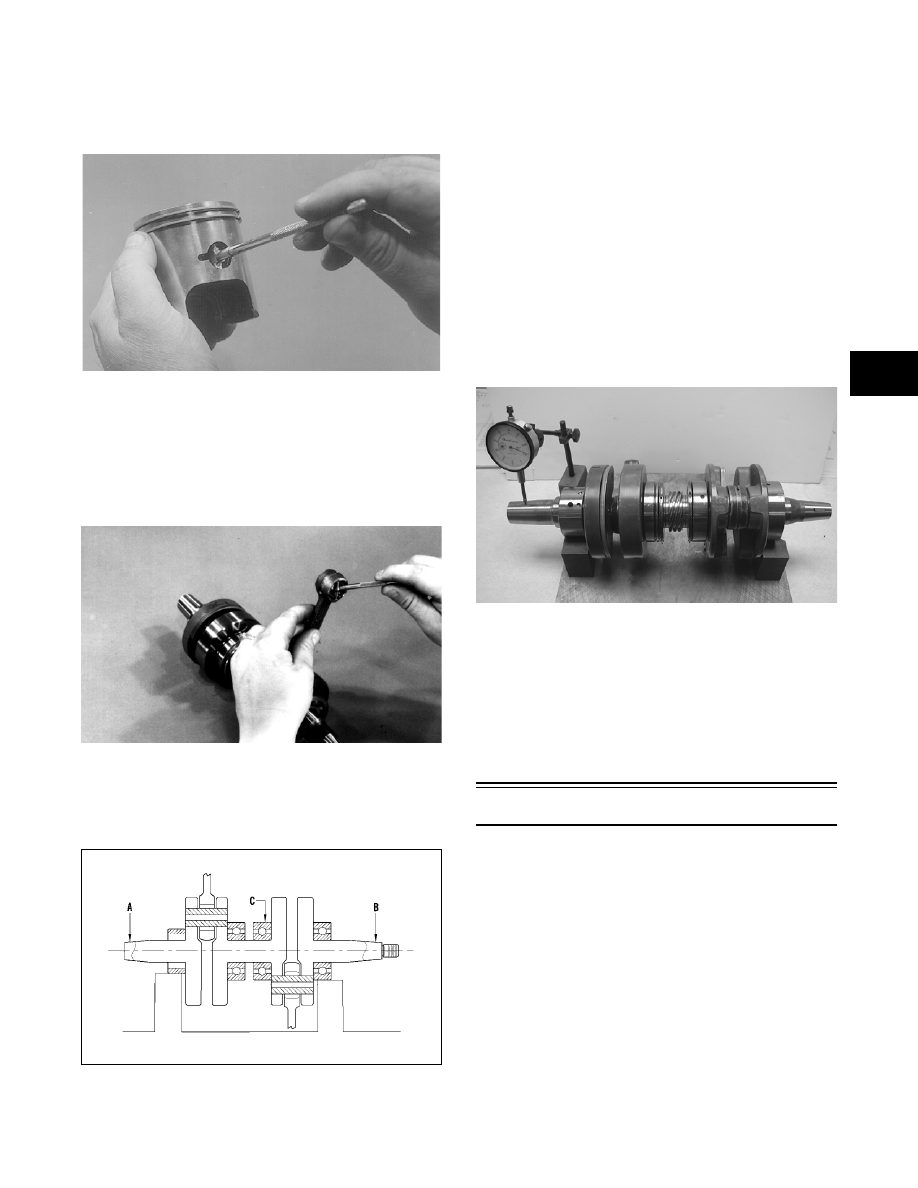

CRANKSHAFT RUNOUT

0742-727

1. Using the V Blocks, support the crankshaft on the

surface plate.

NOTE: The V blocks should support the crank-

shaft on the outer bearings.

2. Mount a dial indicator and base on the surface

plate. Position the indicator contact point against

the crankshaft location point A (PTO-end) from

the crankshaft end. Zero the indicator and rotate

the crankshaft slowly. Note the amount of crank-

shaft runout (total indicator reading).

NOTE: For runout location point specifications,

see Crankshaft Runout Specifications in Section 1

of this manual.

3. Position the indicator contact point against the

crankshaft location point B (MAG-end) from the

crankshaft end. Zero the indicator and rotate the

crankshaft slowly. Note the amount of crankshaft

runout (total indicator reading).

FC046

4. Position the indicator contact point against the

crankshaft at location point C (center). Zero the

indicator and rotate the crankshaft slowly. Note

the amount of crankshaft runout (total indicator

reading).

5. If runout exceeds 0.05 mm (0.002 in.) at any of the

checkpoints, the crankshaft must be either

straightened or replaced.

Assembling Engine

NOTE: The use of new gaskets and seals is rec-

ommended when assembling the engine.

NOTE: Before the engine is assembled, clean the

threads of the cap screws and the threaded areas

of the engine where Loctite will be used.

NOTE: When the use of a lubricant is indicated,

use Arctic Cat 50:1 Injection Oil.