Snowmobile Arctic Cat (2008 year). Manual - part 22

2-25

2

MD0246

Cleaning and Inspecting

Engine

NOTE: Whenever a part is worn excessively,

cracked, or damaged in any way, replacement is

necessary.

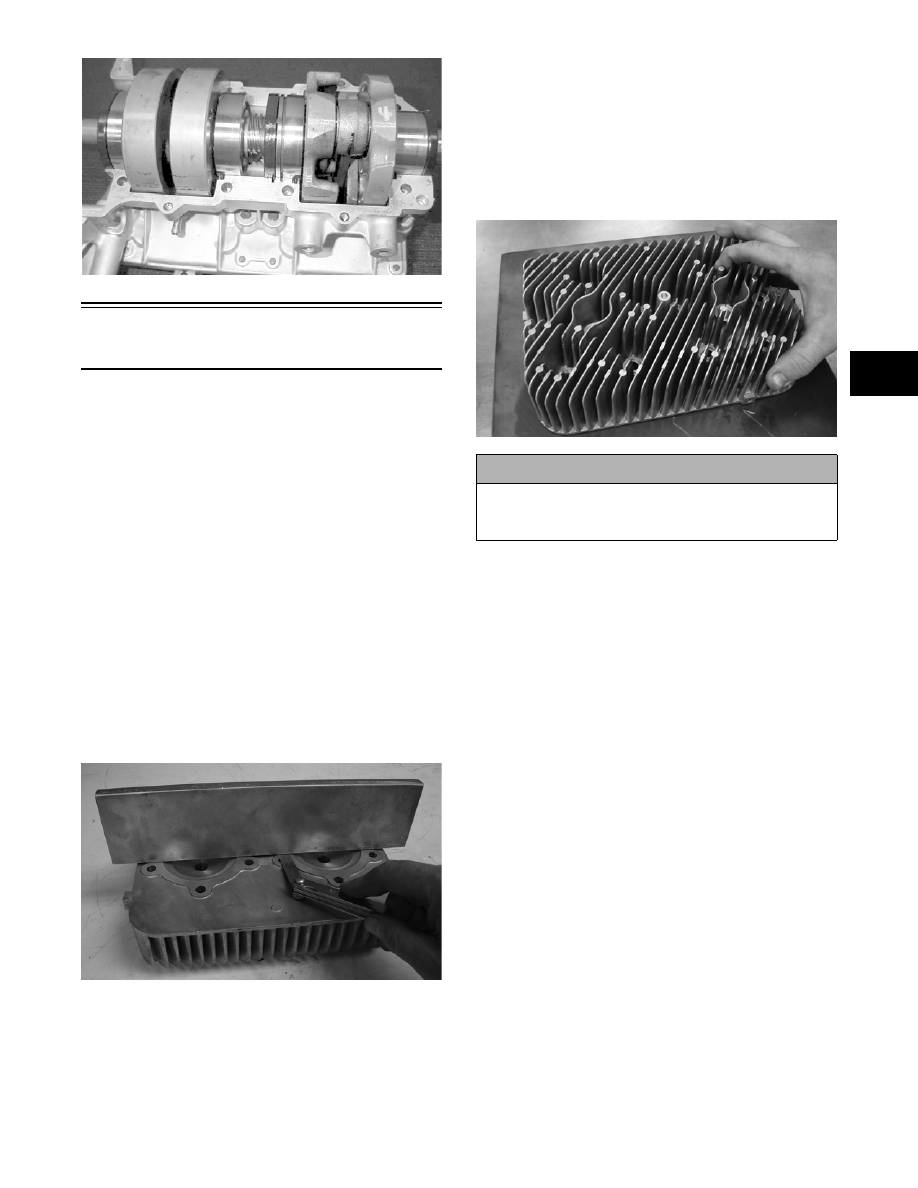

CYLINDER HEAD

1. Using a non-metallic carbon removal tool, remove

any carbon buildup from the combustion chambers

being careful not to nick, scrape, or damage the

combustion chambers or the sealing surfaces.

2. Inspect the spark-plug holes for any damaged

threads.

3. Inspect the cylinder head for flatness using a

straightedge and a feeler gauge. Acceptable

warpage must not exceed 0.05 mm (0.002 in.).

NOTE: If the warpage exceeds specification,

resurface the cylinder head using procedures

identified in step 4.

MD2491

4. Place the cylinder head on a Surface Plate covered

with #400 grit wet-or-dry sandpaper. Using light

pressure, move each cylinder head in a figure eight

motion. Inspect the sealing surface for any indica-

tion of high spots. A high spot can be noted by a

bright metallic finish. Correct any high spots

before assembly by continuing to move the cylin-

der head in a figure eight motion until a uniform

bright metallic finish is attained.

MD2492

CYLINDERS

1. Using a non-metallic carbon removal tool, remove

carbon buildup from the exhaust ports.

2. Wash the cylinders in parts-cleaning solvent.

3. Inspect the cylinders for pitting, scoring, scuffing,

and corrosion. If marks are found, repair the sur-

face with Ball Hone and honing oil.

NOTE: To produce the proper 45° crosshatch

pattern, maintain a low drill RPM. If honing oil is

not available, use a lightweight, petroleum-based

oil. Thoroughly clean the cylinders after honing

using detergent soap and hot water and dry with

compressed air; then immediately apply oil to the

cylinder bores. If a bore is severely damaged or

gouged, the cylinder will have to be replaced.

! CAUTION

Water or parts-cleaning solvent must be used in

conjunction with the wet-or-dry sandpaper or dam-

age to the sealing surface may result.