Snowmobile Arctic Cat (2008 year). Manual - part 23

2-29

2

AQ047

Measuring Critical

Components

CYLINDER HEAD VOLUME

(Squish-Gap Method)

To check the squish gap, a micrometer and two heavy

pieces of solder will be needed.

1. Remove the spark plugs from the engine.

2. Simultaneously insert two pieces of solder down

through the spark plug hole and push them up

against the inner cylinder bore towards the MAG-

side and PTO-side of the cylinder.

3. Pull the recoil rope and crank the engine over sev-

eral times while the solder is being held firmly in

place.

4. Remove both pieces of solder from the cylinder.

Using the micrometer, measure the very end of the

squeezed solder piece. Record the reading.

NOTE: If the solder hasn’t been squeezed by the

piston, a larger piece of solder must be used.

Repeat procedure.

5. Using the opposite end of the solder pieces, insert

them down through the spark plug hole towards

the PTO-side and MAG-side of the cylinder. Push

on the solder until they contact the inner cylinder

bore.

6. Pull the recoil rope and crank the engine over sev-

eral times. Remove both pieces of solder from the

cylinder and measure the opposite squeezed ends

with a micrometer. Record reading.

NOTE: Measure from PTO to MAG-side of the pis-

ton to accurately measure the squish gap. Never

measure across piston, exhaust to carburetor

side, as the piston will rock and the reading won’t

be accurate.

Readings may vary from side to side.

NOTE: Make sure the smaller reading is 1.69 mm

(0.066 in.) or less.

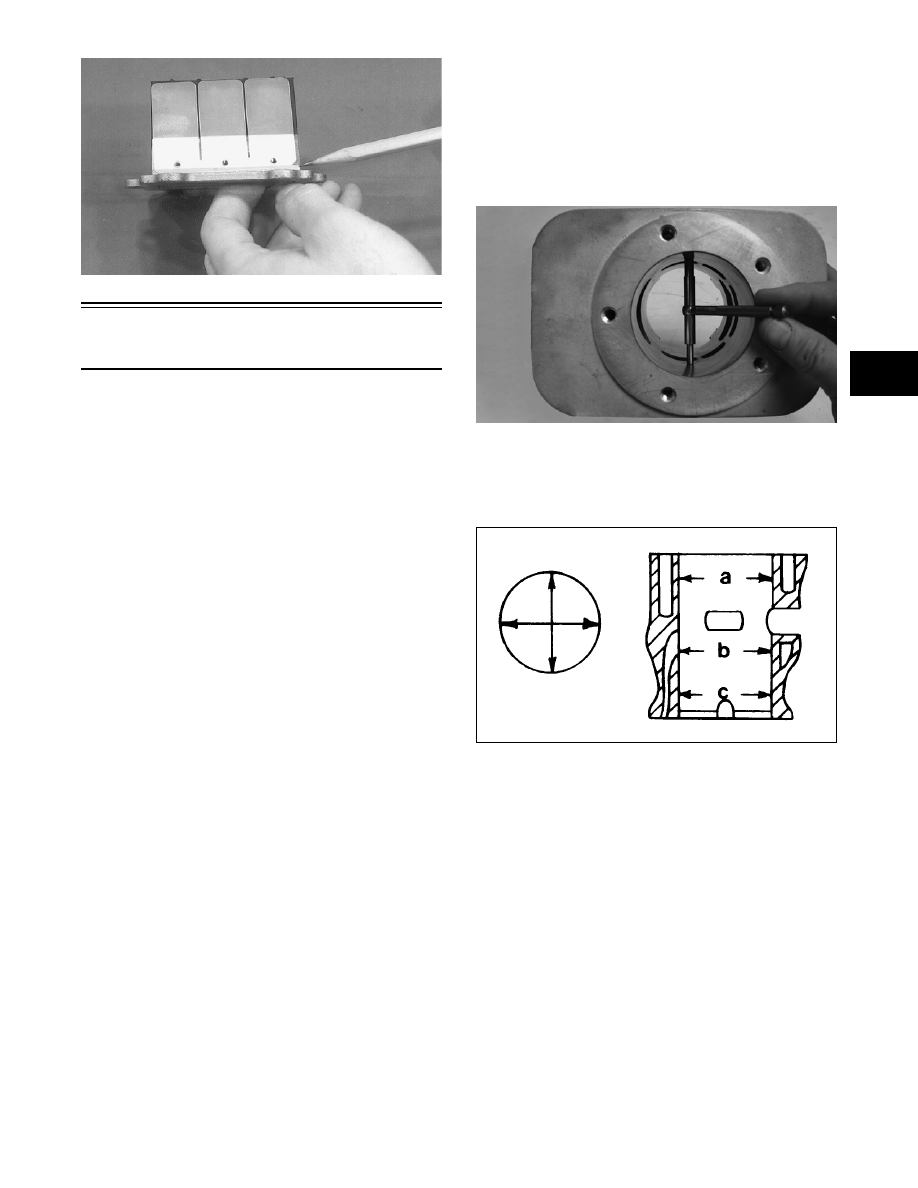

CYLINDER TRUENESS

1. Measure each cylinder in the three locations from

front to back and side to side for a total of six read-

ings.

MD2493

2. The trueness (out-of-roundness) is the difference

between the highest and lowest reading. Maxi-

mum trueness (out-of-roundness) must not exceed

0.1 mm (0.004 in.).

0725-586

PISTON SKIRT/CYLINDER

CLEARANCE

1. Measure each cylinder front to back about 2.5 cm

(1 in.) from the bottom of each cylinder.

2. Measure the corresponding piston skirt diameter at a

point 1 cm above the piston skirt at a right angle to

the piston-pin bore. Subtract this measurement from

the measurement in step 1. The difference (clear-

ance) must be within 0.085-0.115 mm (0.0035-

0.0045 in.).