Snowmobile Polaris 2006 - 2007 FS / FST. Manual - part 45

8.15

PVT System

8

Rev. 1 07/2006

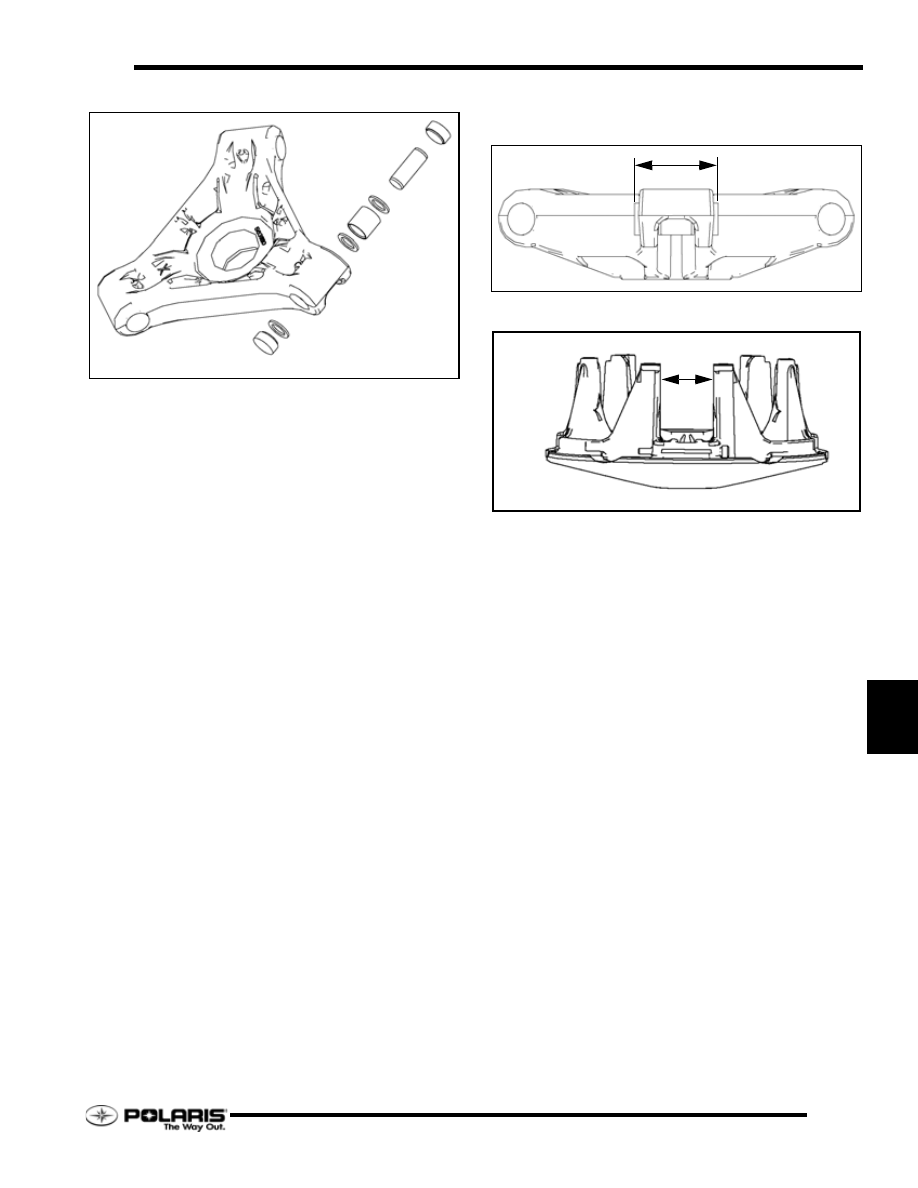

Roller Removal

1.

With the spider in a vise start removing the spider buttons

by drilling a 0.18" hole in the center of a button on one side

of the spider.

2.

Place spider on a vise or in an arbor press.

3.

Place a pin punch through the spider button hole and drive

the opposite button and pin out.

4.

Remove shims (if any are installed) and note their location.

5.

Flip the spider over and tap out the holed button.

Roller Installation

NOTE: CAUTION: Use care to start the pin straight.

Aluminum burrs could pass through into the roller

bushing causing it to bind and stick. Also use care

to make sure the roller remains aligned when the pin

is driven through. The roller busing could be

damaged causing premature wear and roller failure.

1.

Drive pin into the spider leg.100" -.125" (0.25 - 0.32cm)

beyond the first land of the spider leg.

2.

Install one washer on the portion of the pin that is

protruding from the spider leg.

3.

Install new buttons into the spider

4.

Place roller in spider leg and center it on the pin.

5.

Place a second washer on the other side of the roller.

6.

Place the spider on a vise.

7.

Install pin centering tool (PN 2870401).

8.

Drive the roller pin through the second land of the spider.

9.

Repeat process for the other two rollers.

10. Measure the width of the spider leg with the buttons

installed (9) and record the measurement. Specification is

1.496" (37.99mm).

11. Measure the width of the moveable sheave towers.

Specification is 1.50" (38.1mm).

12. Subtract the spider measurement form the tower

measurement. The clearance between the spider buttons

and the moveable sheave towers is .002" - .004" (.05 -

.10mm).

SPIDER

BUTTON

SHIM

WASHER

ROLLER

ROLLER PIN

WASHER