Snowmobile Polaris 2006 - 2007 FS / FST. Manual - part 44

8.11

PVT System

8

Rev. 1 07/2006

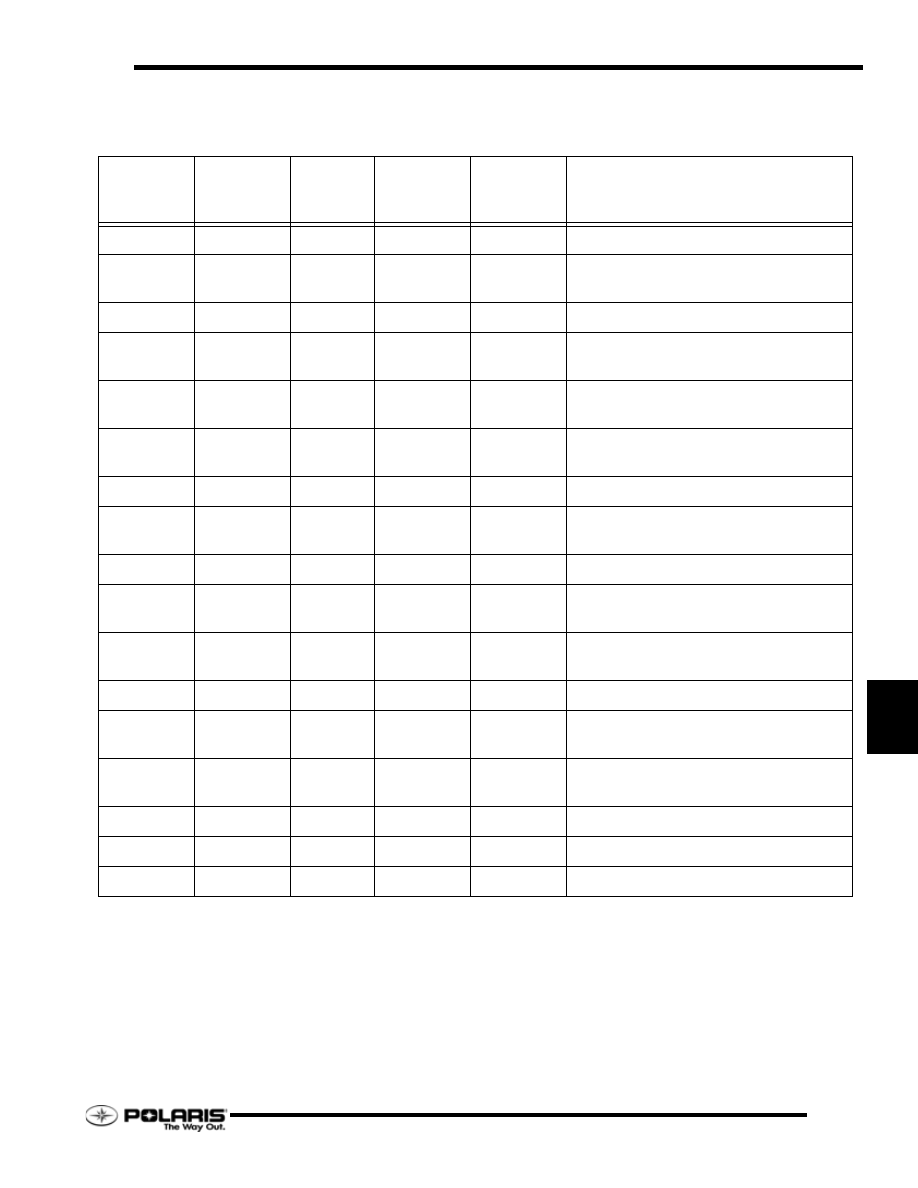

Drive Belts

*Belt dimensions are given in nominal dimensions. There is a +/

- variance for all critical dimensions. Clutch set up must be

inspected when a new belt is installed and, if necessary adjusted.

The drive belt is an important component of the converter

system. In order to achieve maximum efficiency from the

converter, drive belt tension (deflection), clutch offset, and

alignment must be adjusted properly.

Part

Number

Belt Width

(Projected)*

in/mm

Side

Angle

Overall*

Center to

Center in/

cm*

Outer

Circumfere

nce in/cm

Notes

3211042

1.375/34.9

32_

12/30

47.25/120

Common production belt.

3211045

1.375/34.9

32_

12/30

47.125/

119.7

Close tolerance version of 3211042

3211058

1.250/31.75

28_

11/28

43.313/110

P-90 belt

3211059

1.250/31.75

28_

12/30

45.125/

114.6

Longer P-90 belt

3211061

1.375/34.9

32_

12/30

47.188/

119.9

CVT version of 3211045

3211065

1.438/36.5

28_

12.5/31.75

48.375/

122.9

CVT Double Cog Storm belt

3211066

1.375/34.9

28_

12/30

47.25/120

Double Cog-CVT- thicker than the 3211070.

3211067

1.375/34.9

28_

12/30

47.25/120

“Sticky compound” Good for low

horsepower trail riding. Drag racing belt.

3211070

1.375 / 34.9

28_

12/30

47.25/120

Late model P-85 systems

3211073

1.438 / 36.5

28_

12.5/31.75

48.375/

122.9

“Sticky compound” Good for low

horsepower trail riding. Drag racing belt.

3211074

1.438 / 36.5

28_

12/30

47.625/121

“Sticky compound” Good for low

horsepower trail riding. Drag racing belt.

3211075

1.438 / 36.5

28_

12/30

47.625/121

Double Cog CVT

3211080

1.438 / 36.5

28_

11.5/29.2

46.625/

118.4

Double Cog CVT version of 3211078

3211078

1.438 / 36.5

28_

11.5/29.2

46.62 /

118.4

Standard Drive Belt

3211099

1.490 / 37.84

28_

11 / 27.9

46.06 / 116.9

Double Cog CVT

3211111

1.537 / 39

28_

11.5/29.2

47.67 / 121

Super Cog Belt

3211115

1.46 / 37.1

26_

11.5 / 29.2

46.77 / 118.8

MBL Drive Belt