Snowmobile Polaris (2006 year). Manual - part 35

6.26

ENGINE

The long studs are installed to a height of 3.66" (93mm). The

small studs are installed to a height of 2.16" (55mm).

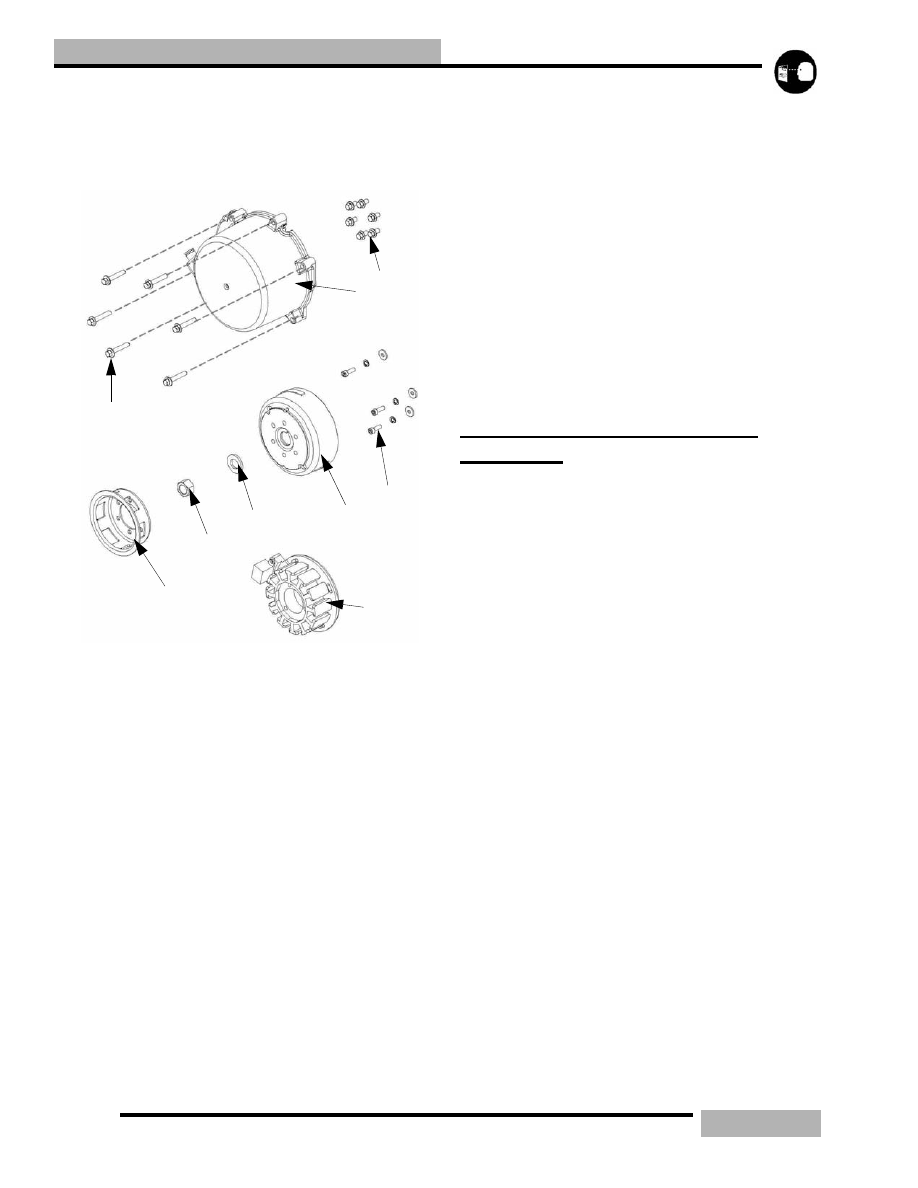

500/600 RECOIL/STATOR REMOVAL

1.

Remove the recoil cover (2).

2.

Remove the recoil basket bolts (1) and the recoil basket

(4).

3.

Using a strap wrench PN PU-45419 hold the flywheel

while taking the flywheel nut (5) and washer (6) off.

4.

Using the Flywheel Puller PN 2871043, thread the puller

bolts into the flywheel. Do not install puller bolts more

than 5/16, (7mm) into flywheel threads or stator damage

may result.

5.

Tighten the center bolt and remove the flywheel (7).

6.

Note the ignition timing marks that match up with the

stator to the crankcase or scribe additional marks for

reference for assembly.

7.

Remove the stator bolts (8), and remove the stator (9). Be

careful when removing the wires of the stator.

500/600 RECOIL/STATOR ASSEMBLY

NOTE: Inspect all parts for wear or damage during

disassembly. Replace all seals, o-rings, and gaskets

with Genuine Pure Polaris parts during assembly.

Refer General chapter for general inspection

procedures.

1.

Install the stator (9) and align the timing marks that was

noted earlier.

2.

Apply Loctite 242 to the first few threads of the stator

bolts (8) and torque to 5 ft-lb (7Nm).

3.

Install the flywheel (7) so that it matches up with the index

of the woodruff key.

4.

Apply Loctite 242 to the threads of the flywheel nut (5)

and place the washer (6) and nut onto the end of the

crankshaft.

5.

Holding the flywheel with the strap wrench, torque the

flywheel nut to 90 ft-lb (122Nm).

6.

Install the recoil basket (4) and the recoil basket bolts (3)

on the flywheel and torque the bolts to 9 ft-lb (12Nm).

7.

Install recoil assembly (2) and torque the recoil assembly

bolts (1) to 9 ft-lb (12Nm).

340/550 FUJI ENGINE/500

LIBERTY

340/550 FUJI/500 LIBERTY ENGINE

REMOVAL/INSTALLATION

1.

Turn the fuel valve to the “OFF” position.

2.

Remove the exhaust system.

3.

Disconnect the battery ground (-) if applicable.

4.

Disconnect the CDI box.

5.

Remove the spark plug leads form the spark plugs.

6.

Disconnect the stator connection(s).

7.

Remove the air box.

8.

Remove the drive belt.

9.

Remove the drive and driven clutches.

10. Remove the recoil handle and secure the rope so that it is

on the recoil housing.

11. Loosen the carburetor clamps that are holding the

carburetor onto the boots.

12. Separate the carburetors and secure them out of the way

for engine removal.

13. Disconnect the oil pump cable from the oil pump.

14. Disconnect the oil supply line at the oil pump, and plug the

end with a clean bolt.

15. Remove the fuel pump impulse line from the engine.

16. Remove all the motor mount nuts.

17. Remove the engine.

18. Install in reverse order.

1

2

4

5

6

7

8

9

3

9(12)

90(122)

5(7)