Snowmobile Polaris (2006 year). Manual - part 34

6.22

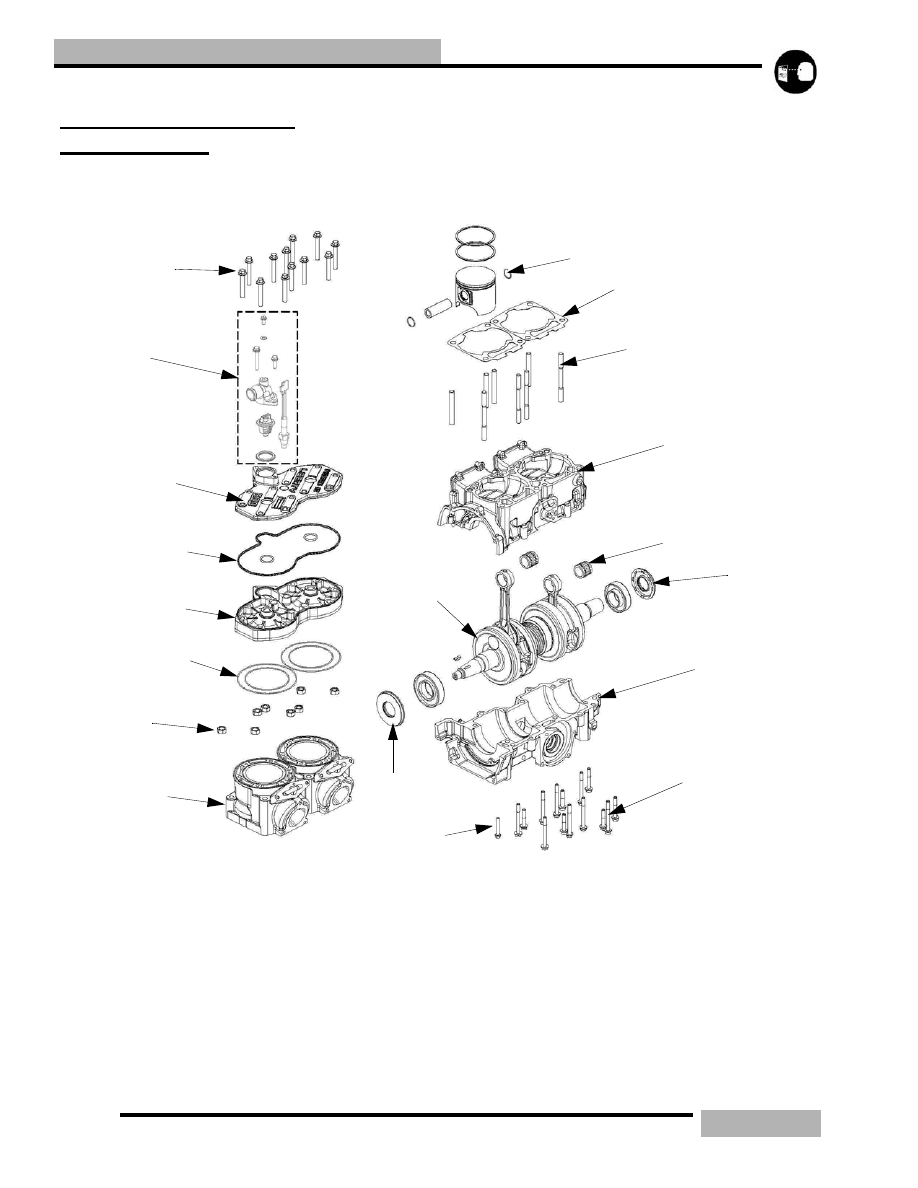

ENGINE

500/600 HO ENGINE

REBUILDING

500/600 LIBERTY ENGINE DISASSEMBLY

1.

Remove reed valve assembly

2.

Remove the head bolts (1).

3.

Remove the head cover (3) and the rubber head seals (4).

4.

Remove the head (5) and cylinder o-rings (6).

5.

Remove the VES assembly. ‘EXHAUST VALVE

REMOVAL” on page 6.2.

6.

Remove the cylinder nuts (7) and carefully remove the

cylinders (8) with a slight rocking motion.

7.

Remove the c-clips that hold the wrist pin into the piston

(9).

8.

Using the piston pin puller PN 2870386 remove the piston

pins, and the piston from the crankshaft (15).

9.

Remove the water pump cover.

10. Remove the water/oil pump assembly. ‘500/600

LIBERTY WATER/OIL PUMP CROSS SHAFT

DISASSEMBLY” on page 6.24.

11. If removing the engine mounting straps (these straps are

mounted to the engine and bulkhead) label the direction

and placement of each engine strap.

12. Remove the cylinder base gaskets (10) and replace if

damaged.

13. Turn over the crankcase and remove the bottom crankcase

1

2

3

4

5

6

7

8

9

10

11

12

13

15

16

18

14

14

22(29.8)

32(43.4)

22(29.8)

17

5(6.8)