Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 885

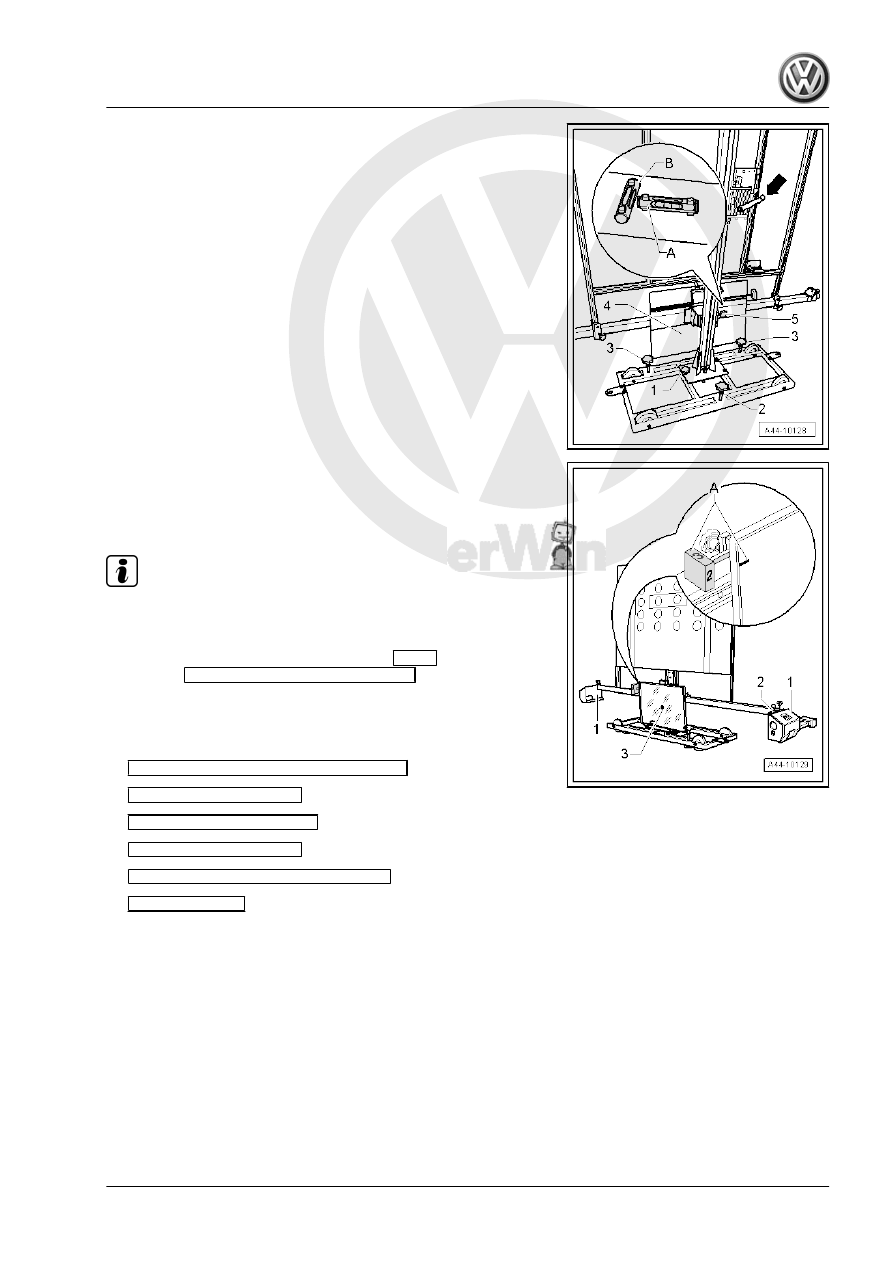

– Turn the precision adjustment screw -5- until the display on

the wheel alignment computer is located within the tolerance

range.

– Level the bubble levels -2- of the measurement sensor -1-.

– Using the laser beam -3- on the ACC Reflector Mirror - Audi -

VAS6430/3- , check whether the bubble level is level and the

laser beam is in the center of the sensor lens.

Note

If the laser beam does not meet the sensor lens, the ACC Re‐

flector Mirror - Audi - VAS6430/3- must be aligned again.

– On the Vehicle Diagnostic Tester , press

GO TO

and select the

function

Function/Component Selection

.

Selection on the Vehicle Diagnostic Tester for the adjustment of

the Distance Regulation Control Module - J428- :

– Press the following buttons one after another on the screen:

♦

Chassis (Repair Group 01; 40 - 49)

♦

13 - Distance Control

♦

01 - OBD-Capable System

♦

13 - Distance Control

♦

13 - Distance Control, Functions

♦

13 - Calibrate

Follow the instructions on the screen to perform the adjustment.