Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 866

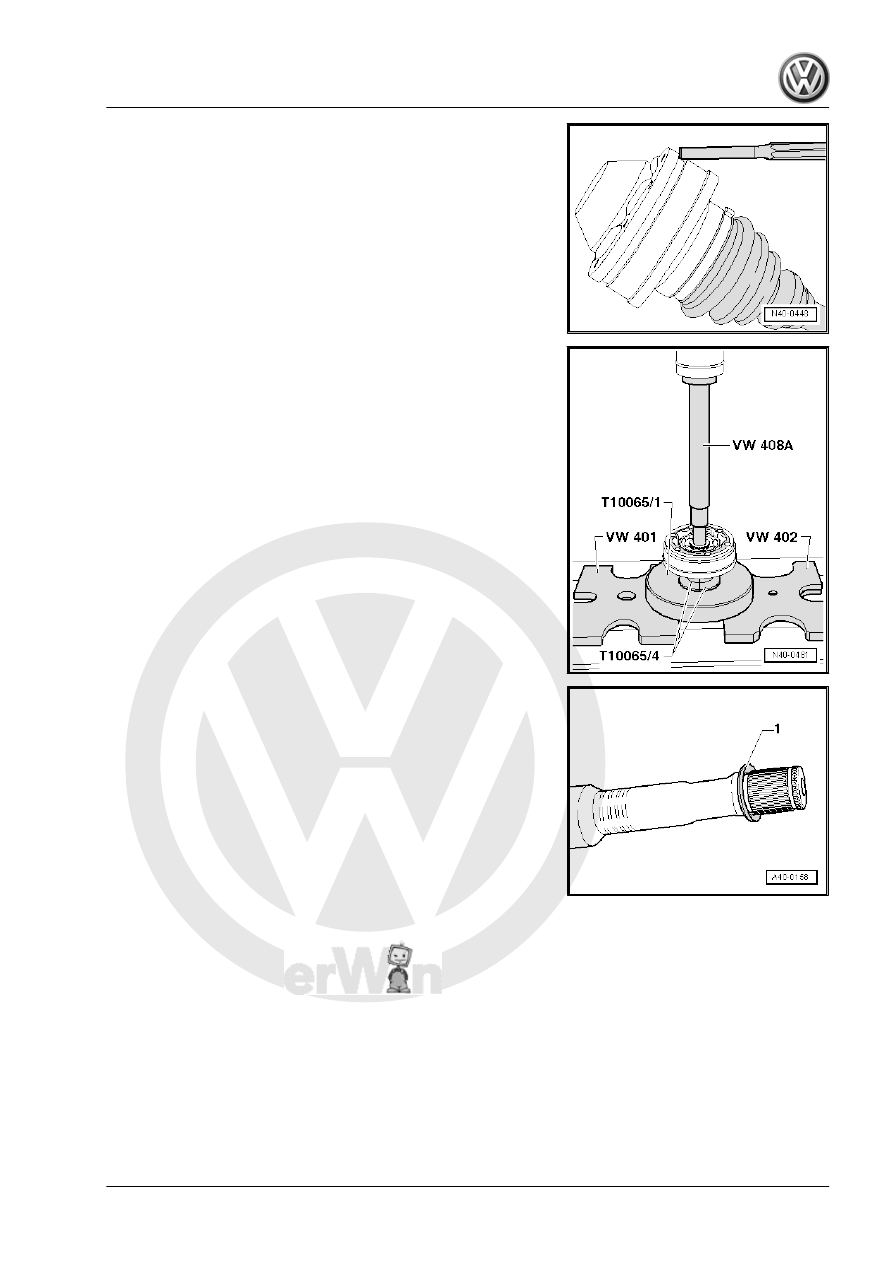

Drive Off Cover for Inner Joint

Removing the Inner CV Joint

– Press off CV from joint using drift.

– Remove the circlip.

– Remove both clamps, and push the CV boot toward outer joint.

Assembling

Installed Location of the Plate Spring on Inner Joint

1 - Plate Spring