Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 831

Tightening Clamping Sleeve On Outer Joint

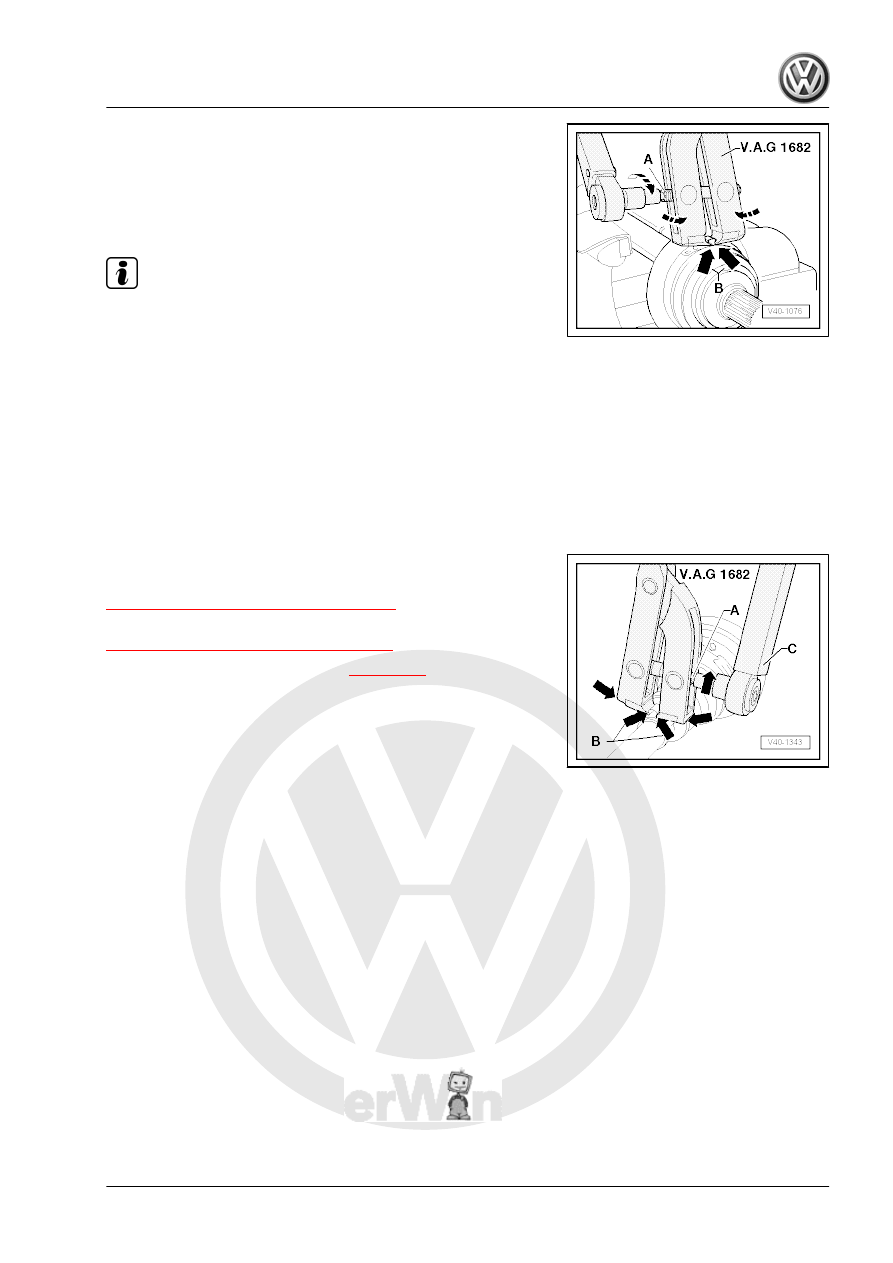

– Position Clamping Pliers - VAG1682A- as shown in illustration.

When doing this, make sure that edges of clamping pliers are

seated in corners -arrows B- of clamp.

– Tension clamp by turning spindle with a torque wrench (do not

tilt clamp tool).

Note

♦

The hard material of the joint boot (compared to rubber) makes

it necessary to use a stainless steel hose clamp. It is only pos‐

sible to tighten the hose clamp with Clamping Pliers -

VAG1682A- .

♦

Tightening specification: 25 Nm.

♦

Use torque wrench -C- with adjustment range 5 to 50 Nm (for

example Torque Wrench 5-50Nm - VAG1331- ).

♦

Be sure thread of spindle -A- of clamp tool moves freely.

Grease with MOS 2 grease if necessary.

♦

If the thread is tight, for example, dirty, the required tensioning

force for the hose clamp will not be achieved in spite of correct

torque specification settings.

Tensioning Clamp On Small Diameter

Outer CV joint, checking. Refer to

⇒ “6.7 Outer CV Joint, Checking”, page 113

Inner CV joint, checking. Refer to

⇒ “6.8 Inner CV Joint, Checking”, page 114

CV joint, checking function. Refer to

6.6.3

Drive Axle, Disassembling and Assem‐

bling, Triple Roller Joint AAR3300i

Special tools and workshop equipment required

♦ Press Plate - VW401-

♦ Press Plate - VW402-

♦ Press Piece - Rod - VW408A-

♦ Press Piece - Multiple Use - VW411-

♦ Press Piece - 37mm - VW416B-

♦ Press Piece - Multiple Use - VW447H-

♦ Hose Clip Pliers - VAG1275A-

♦ Torque Wrench 1331 5-50Nm - VAG1331-

♦ Torque Wrench 1332 40-200Nm - VAG1332-

♦ Clamping Pliers - VAG1682A-

♦ Puller - Driveshaft - T10382/1-

♦ Spindles - T10382/2-