Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 822

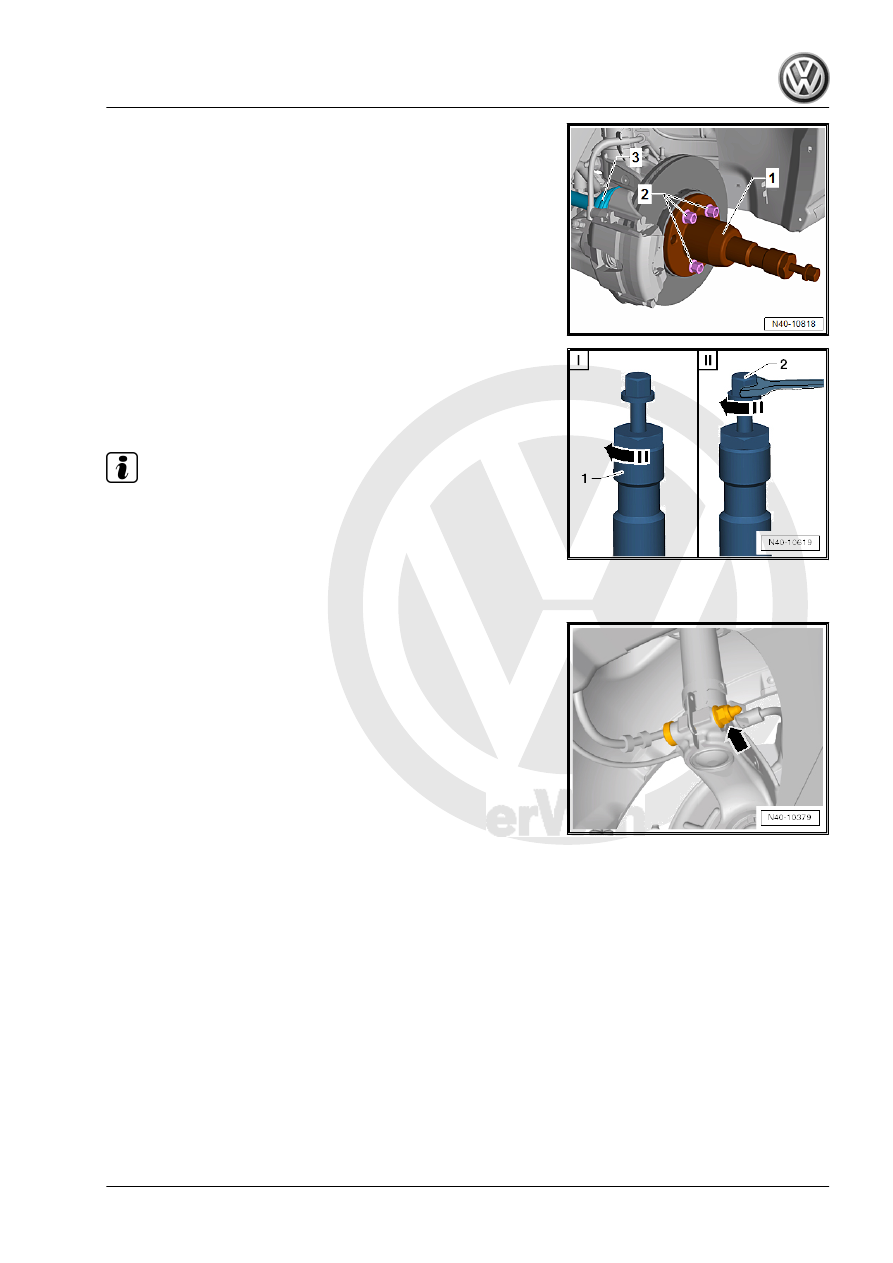

Using the -T10520- :

– Secure the -T10520- -1- with three wheel bolts -2- on the wheel

hub, so that the drive axle -3- can be pressed out.

– Follow the specified sequence exactly.

I - Tighten the knurled nut -1- hand-tight.

II - Only turn the bolt -2- using a wrench and press out the drive

axle using the -T10520- .

Note

At the end of the tasks or to set back, the spindles must be brought

back into the original position so that the hydraulic operation can

be used.

– Secure the drive axle to the body using wire.

– Place the -VAS6931- under the wheel bearing housing.

– Remove the threaded connection on the wheel bearing hous‐

ing/suspension strut -arrow-.