Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 762

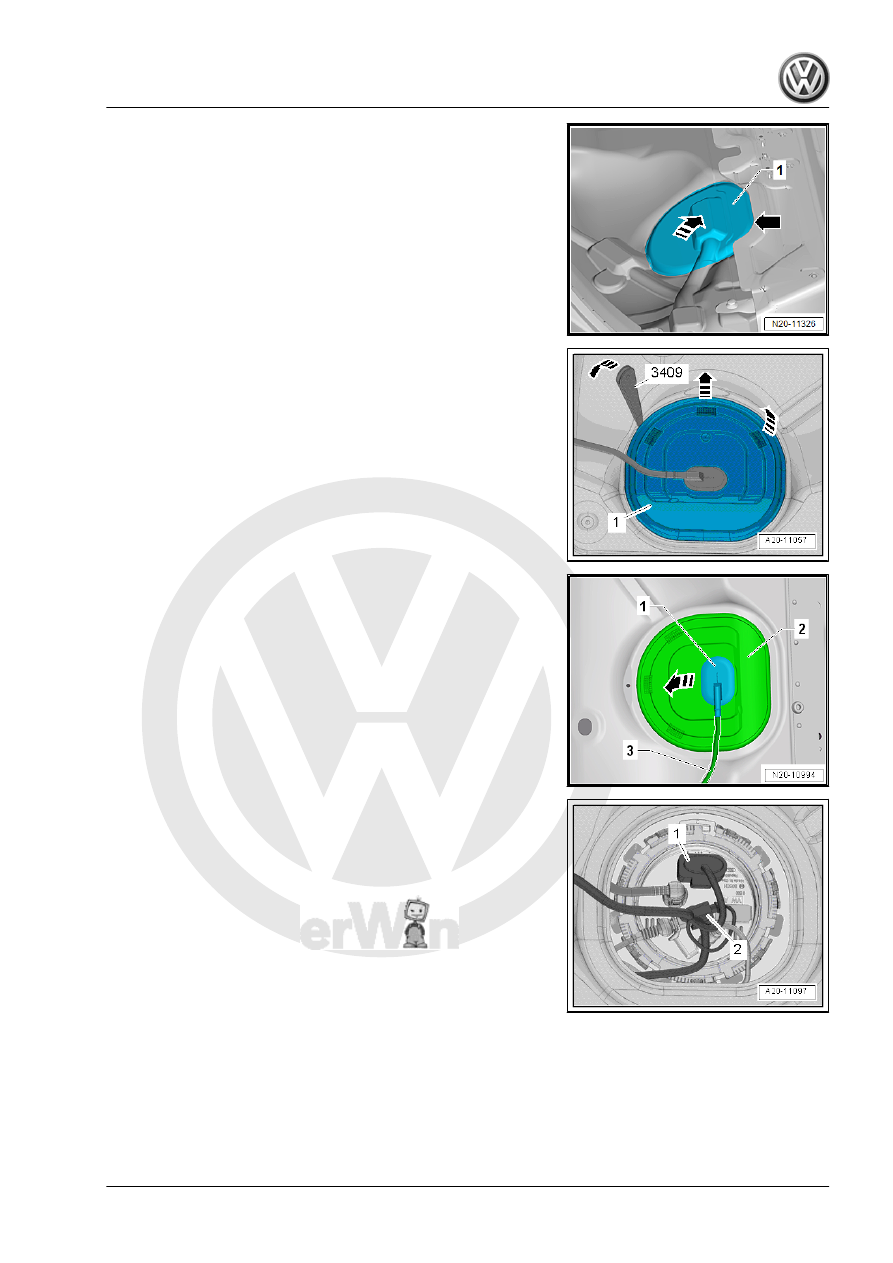

– Partially loosen the cover -1- in the carpet at the separating

line -arrow-.

– Do not separate the cover completely from the carpet so that

later it will be installed correctly.

– Only loosen so far that the cover can be folded up.

– Fold up the cover in the direction of the -arrow-.

Golf and Golf Wagon:

– Remove the rear bench seat. Refer to ⇒ Body Interior; Rep.

Gr. 72 ; Rear Seats; Bench Seat / Single Seats, Removing

and Installing .

Continuation for All Vehicles:

– Unclip the sealing flange cover -1- at the tabs -arrows- using

the -3409- .

– Unclip the grommet -1- downward out of the cover -2-.

– Guide the cover -2- on the wiring harness -3- toward the rear.

– Pull on the connector -1- without pressing the release to make

sure the connection is secure. If the connector was not con‐

nected correctly, it could cause a malfunction.

– Release and disconnect the connector -1-.

– Check the contacts on the connector and on the fuel delivery

unit for damage.