Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 624

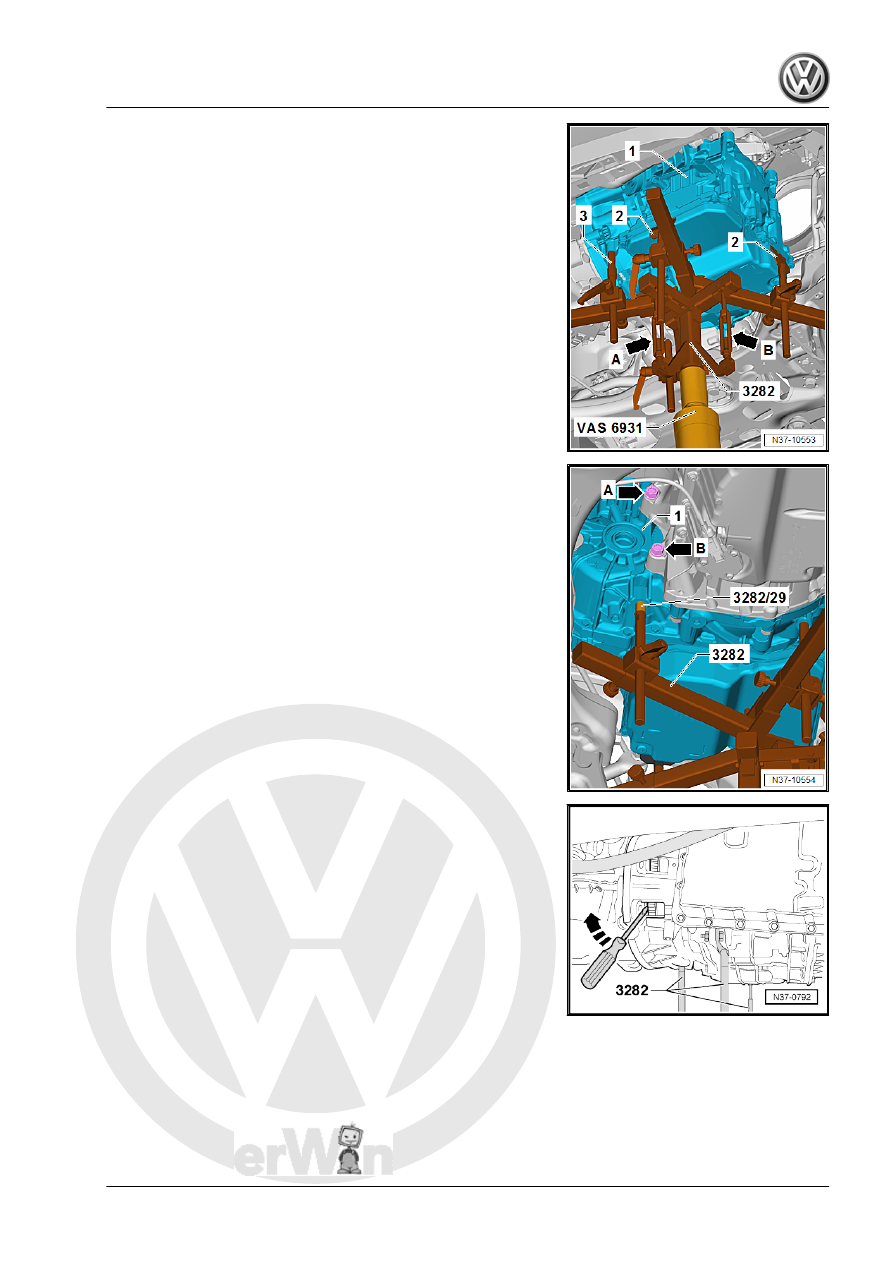

– Place the Transmission Support - 3282- on the Engine and

Gearbox Jack - VAS6931- or Engine/Gearbox Jack -

VAG1383A- .

Install the Transmission Support - 3282- as follows with the

Mounting Element on the transmission:

• The Engine and Gearbox Jack with Transmission Support is

positioned under the transmission -1- so that the spindle

-arrow A- points forward in the direction of travel.

• The spindle -arrow B- points in the direction of travel to the left.

• The Mounts -2- are positioned as shown in the illustration in

the oil pan surrounding groove.

• The Pins -3- lock in the recess on the front right of the trans‐

mission.

– Install the Transmission Support - Pins 29 - 3282/29- into the

rear hole for the pendulum support bolt on the transmission

-1-.

– Support the transmission with the Engine and Gearbox Jack

by carefully lifting.

– Remove the last bolts for the -arrow A- and -arrow B- for the

engine to the transmission. These bolts can be removed with

for example the Socket - Xzn 14 - T10061- .

– While pressing the torque converter off the drive plate, sepa‐

rate the transmission from the engine.

– Guide the transmission past the subframe when lowering it.

Adjust the Transmission Support - 3282- slightly, if necessary.