Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 593

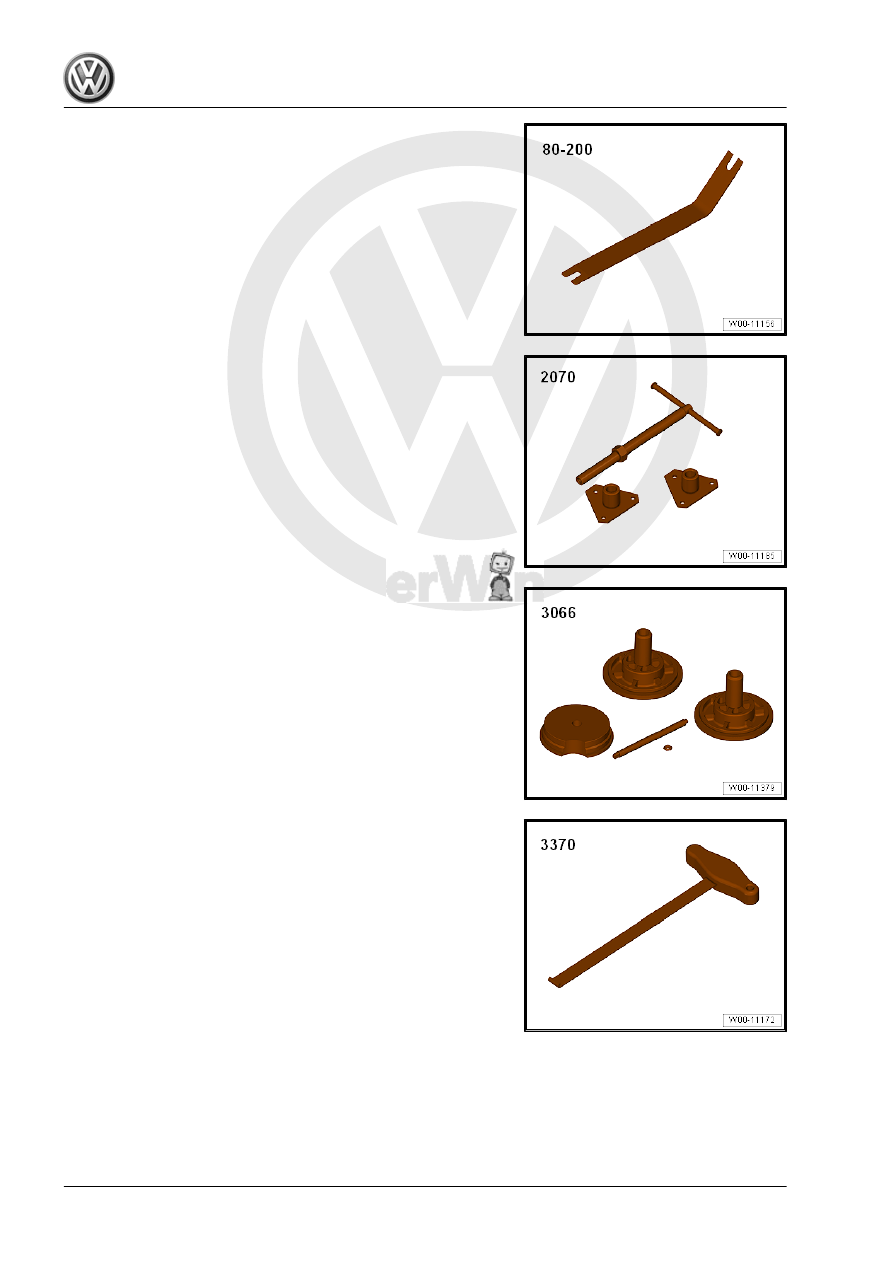

♦ Pry Lever - 80-200-

♦ Spring Strut Compressor - 2070-

♦ Spindle from the Seal Installer - Driver Set - 3066- or M8 x 105

bolt

♦ or the equivalent equipment, Backrest Panel Tool - 3370-

♦ Sealing Compound - AMV 188 200 03-

♦ M8 x 100 mm stud bolt