Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 577

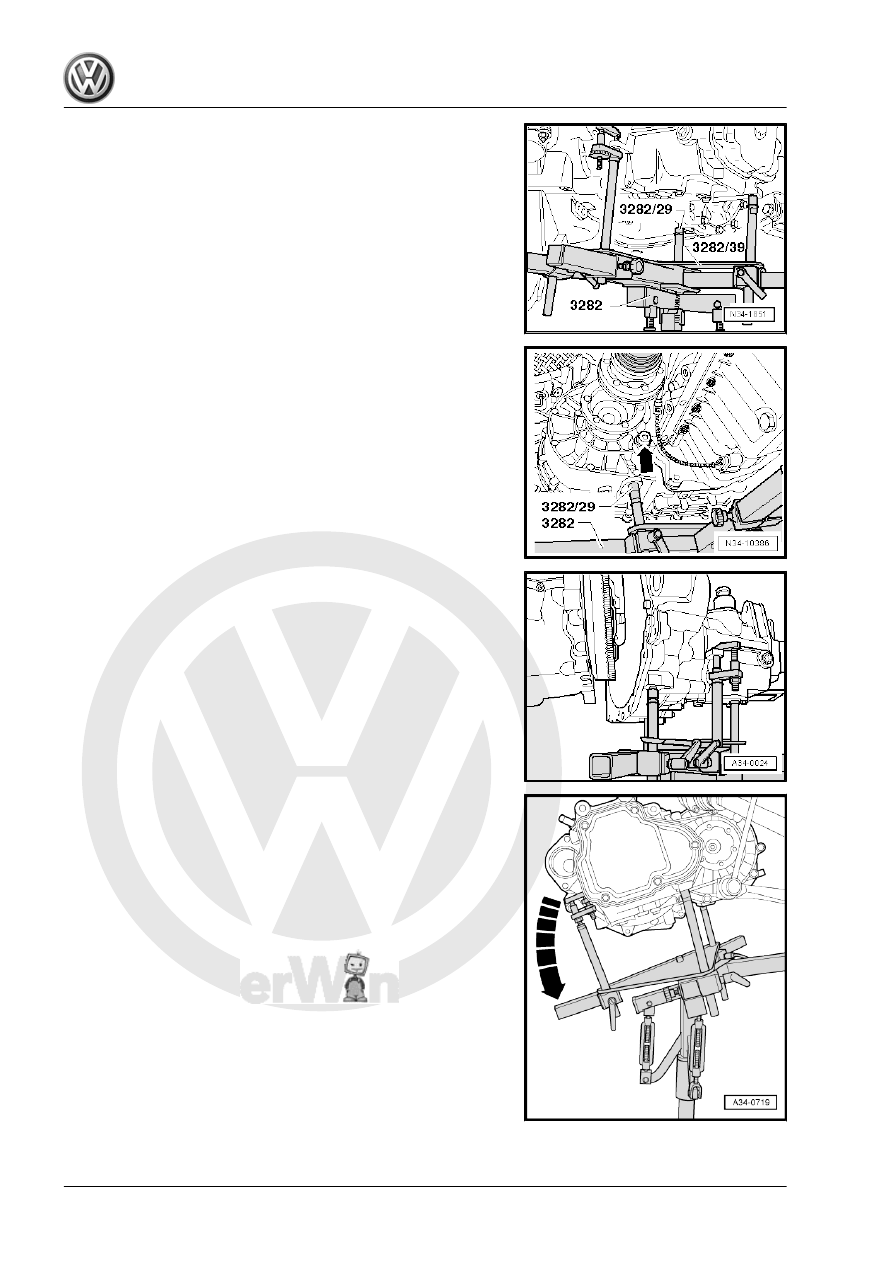

– Align the Adjusting Plate so that it is parallel to the transmis‐

sion and secure the safety support to the transmission.

– Install the Transmission Support - Pins 29 - 3282/29- into the

rear hole for the pendulum support bolt on the transmission.

– Remove the engine/transmission bolt near the right flange

-arrow-.

– Remove the lower engine/transmission bolts.

– Remove the transmission from the alignment bushings and

carefully move it toward the subframe.

– Tip the transmission over the adjusting spindle for the Trans‐

mission Support - 3282- in the direction of -arrow-.

– Carefully push the engine forward slightly with a second tech‐

nician.