Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 529

♦ Slide Hammer - Press Plate - 2050-

♦ Torque Wrench 1331 5-50Nm - VAG1331-

♦ Puller - Kukko Internal - 46-56mm - 21/07-

♦ Puller - Kukko Counterstay - 22/2-

♦ Dial Indicator - VAS6080A-

(Selecting the correct adjusting shim for the output shaft)

It is necessary to adjust the output shaft if the following compo‐

nents were replaced:

♦ Transmission Housing

♦ Clutch Housing

♦ Output shaft, 1st to 4th gears or

♦ Output shaft tapered roller bearing

Adjustment overview. Refer to

⇒ “3 Adjustment Overview”, page 221

Requirements:

• Remove any sealant still on the sealing surfaces on the clutch

and transmission housings.

• Install the output shaft that is going to be measured.

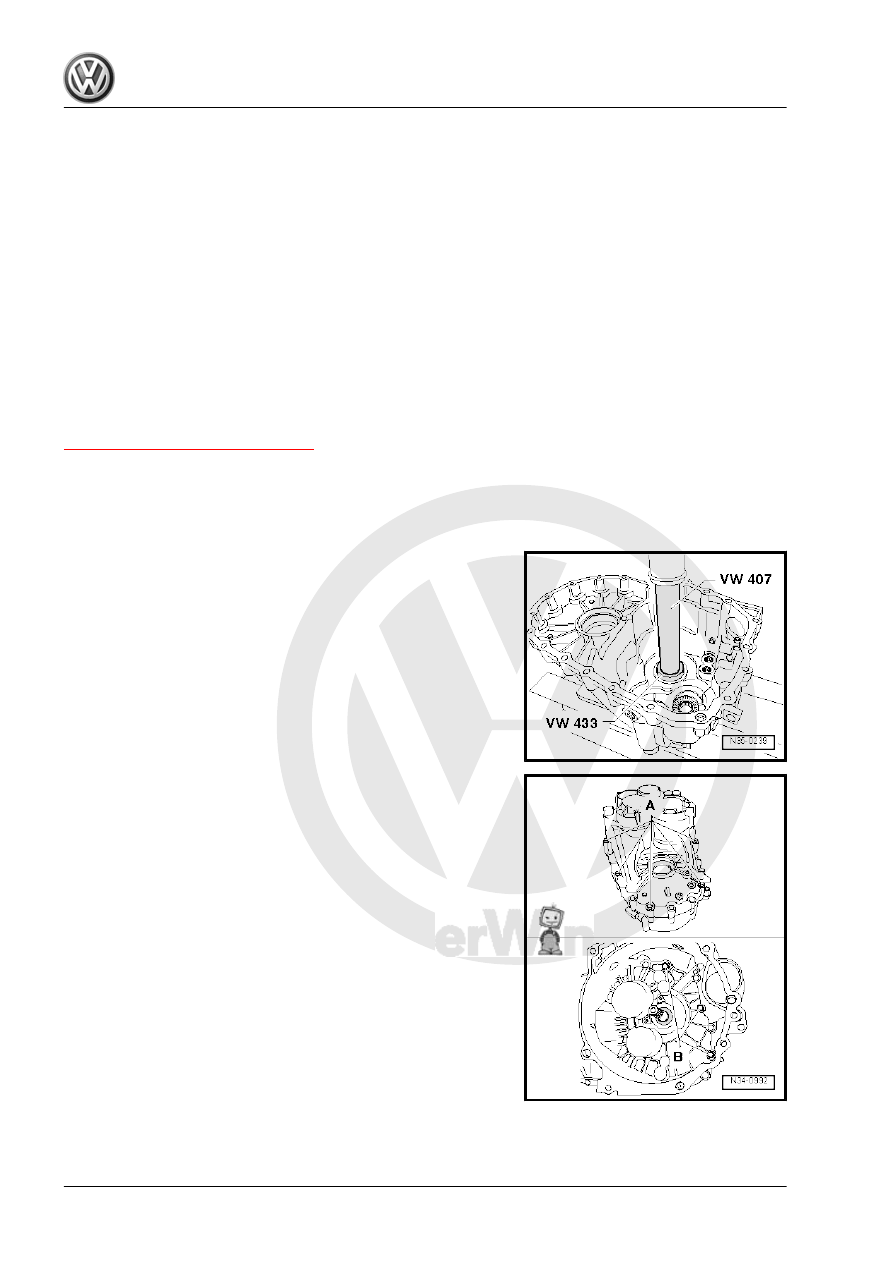

– Install the tapered roller bearing outer race in the transmission

housing with a 1.70 mm shim. Support transmission housing

directly beneath bearing mount using -2050- .

– Install the output shaft for 1st through 4th gears into the clutch

housing.

– Install the transmission housing and tighten the bolts

-A and B- diagonally.