Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 528

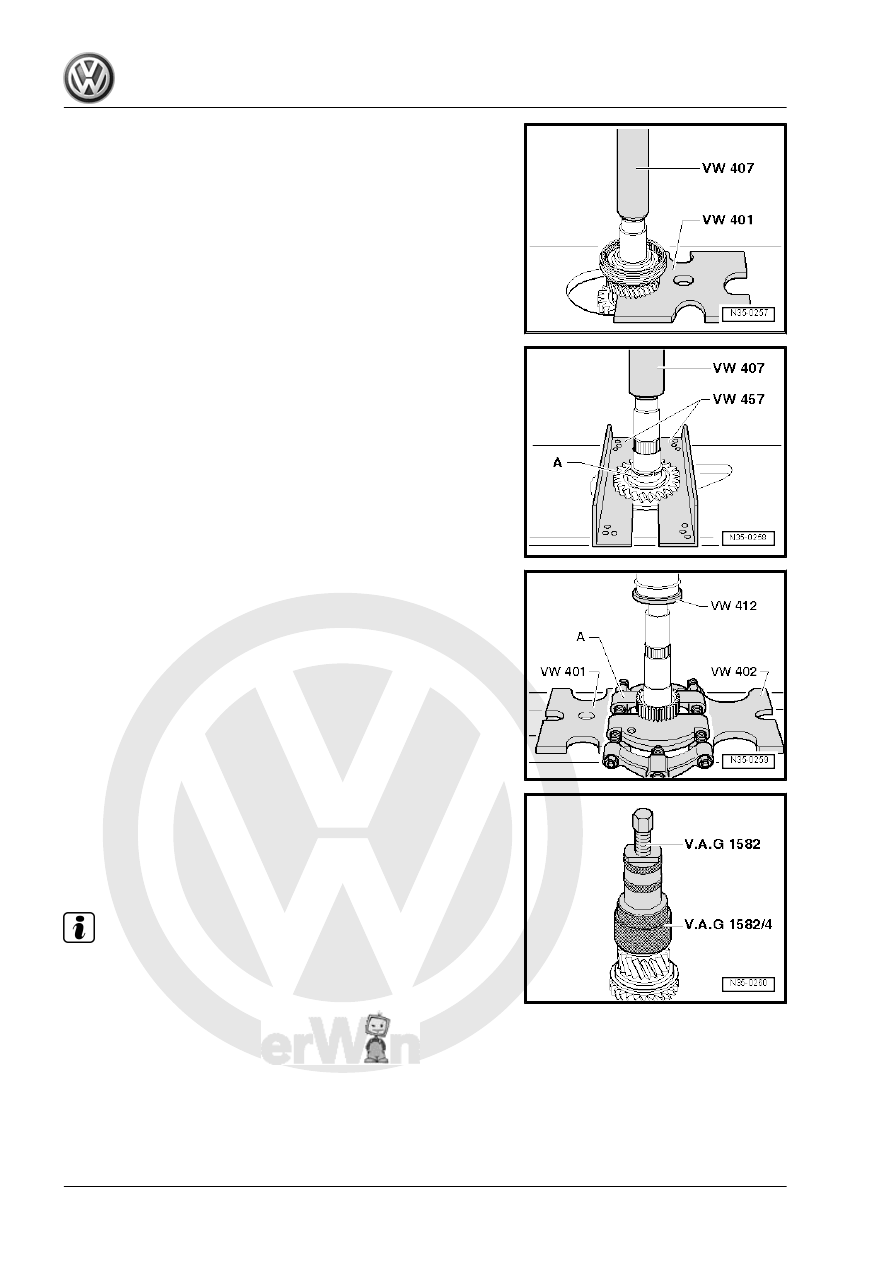

Removing the 5th and 6th Gear Synchronizer Hub/Locking Collar

with the 6th Gear Wheel

– Remove the locking ring beforehand.

Removing the Sleeve -A- together with the Reverse Gear Wheel

– Remove the locking ring beforehand.

Removing the Reverse Gear Synchronizer Hub

– Remove the locking ring beforehand.

A - Separating Tool 22-115mm , for example, -17/2-

Removing the Inner Race/Tapered Roller Bearing on the Side of

the Clutch Housing.

– Mount the -30-11- on the output shaft before removing the

puller.

Assemble the Output Shaft

Note

Heat the inner races of the tapered roller bearing and synchron‐

izer hub to approximately 100 °C (212 °F) with the -VAS6414-

before installing. Press on as far as the stop so there is no axial

play.