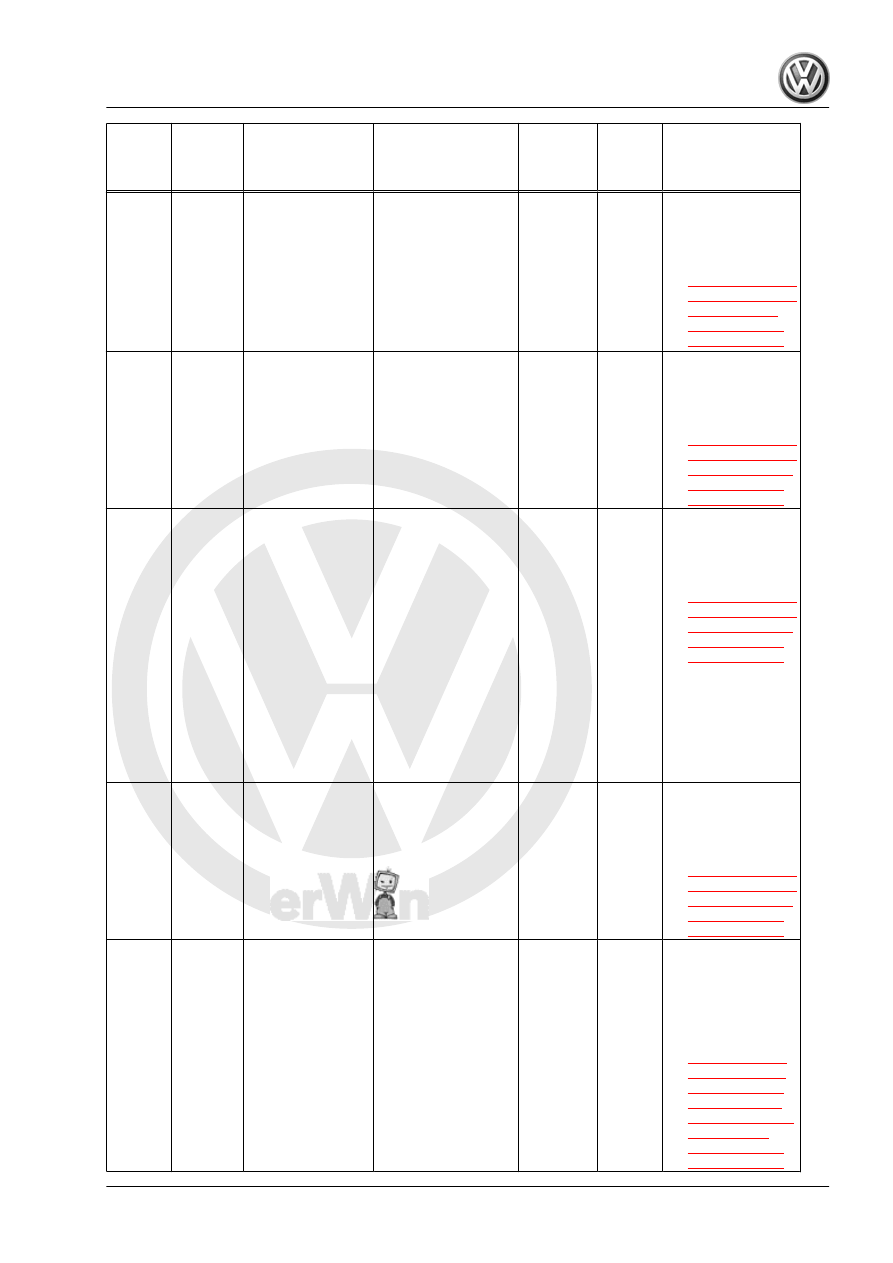

Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 119

DTC /

Descrip‐

tion

Monitor

Strategy

Descrip‐

tion

Malfunction Crite‐

ria and Threshold

Value

Secondary Parame‐

ters with Enable

Conditions

Monitoring

Time

Length

MIL Il‐

lum.

Component Diag‐

nostic Procedure

P2010

Intake

Manifold

Runner

Control

Circuit

High

Bank 1

Intake

Manifold

Runner

Flap Ac‐

tuator

Short To

Battery

Plus

• Power stage

temperature >

160 – 200° C

• Or

• Output current

(hardware val‐

ues) > 4.0 – 7.0

A

• Engine running

• Actuator com‐

manded on

• 2.0 s

• Contin‐

uous

• 2

DCY

– Check the In‐

take Manifold

Runner Control

Valve - N316- .

Refer to

P2014

Intake

Manifold

Runner

Position

Sensor/

Switch

Circuit

Bank 1

Intake

Manifold

Runner

Flap Po‐

sition

Sensor

Short To

Ground /

Open Cir‐

cuit

• Intake manifold

runner flap po‐

sition sensor

voltage < 0.20

V

• Engine start not

active

• 0.04 s

• Contin‐

uous

• 2

DCY

– Check the In‐

take Manifold

Runner Position

Sensor - G336- .

Refer to

P2015

Intake

Manifold

Runner

Position

Sensor/

Switch

Circuit

Range/

Per‐

for‐

mance

Bank 1

Intake

Manifold

Runner

Flap Ac‐

tuator

Adapta‐

tion Val‐

ue Moni‐

toring

• Diff. actual val‐

ue vs. substitu‐

tion value @

lower mechani‐

cal thresh hold

> 0.70 V

• Or

• Diff. actual val‐

ue vs. substitu‐

tion value @

upper mechan‐

ical thresh hold

> 0.70 V

• Failed adapta‐

tions >= 1.00 [-]

• Modeled air tem‐

perature < 0.75 [-]

• Engine running

• Engine speed >

640; < 1,504

RPM

• ECT @ cylinder

head > -30° C

• Intake manifold

runner flap adap‐

tation not finished

• 0.04 s

• Once

per life‐

time

• 2

DCY

– Check the In‐

take Manifold

Runner Position

Sensor - G336- .

Refer to

P2017

Intake

Manifold

Runner

Position

Sensor/

Switch

Circuit

High

Bank 1

Intake

Manifold

Runner

Flap Po‐

sition

Sensor

Short To

Battery

Voltage

• Intake manifold

runner flap po‐

sition sensor

voltage > 4.80

V

• Engine start not

active

• 0.04 s

• Contin‐

uous

• 2

DCY

– Check the In‐

take Manifold

Runner Position

Sensor - G336- .

Refer to

P2024

EVAP

Fuel Va‐

por

Temper‐

ature

Sensor

Circuit

Smart

Tempera‐

ture Sen‐

sor Open

Circuit

• NVLD output

voltage lower

range >= 1.92 –

2.21 V

• NVLD output

voltage upper

range <= 2.85 –

3.25 V

• Case 1:

• Ignition on

• Case 2:

• Ignition off (dur‐

ing ECM keep

alive-time)

• 0.5 s

• Contin‐

uous

• 2

DCY

– Check the Fuel

Tank Leak De‐

tection Control

Module - J909- /

Fuel Tank Pres‐

sure Sensor -

G400- . Refer to

GTI 2014 ➤

Generic Scan Tool - Edition 04.2015

3. Diagnosis and Testing

149