Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 58

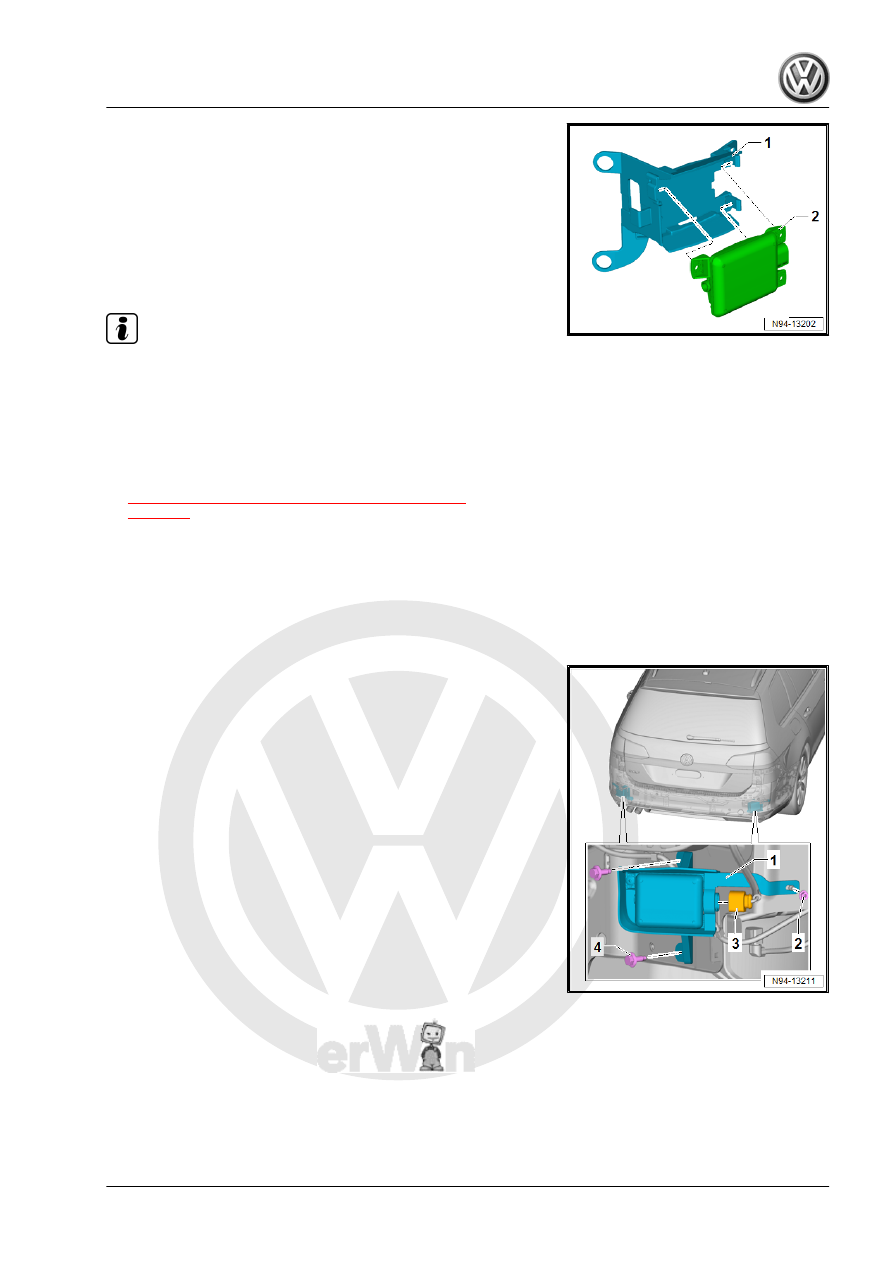

– Remove the Blind Spot Detection Control Module - J1086- /

Blind Spot Detection Control Module 2 - J1087- with the brack‐

et -1-.

– Remove the Blind Spot Detection Control Module - J1086- /

Blind Spot Detection Control Module 2 - J1087- -2- from the

bracket -1-.

Installing

Install in the reverse order of removal while paying attention to

the following:

Note

♦

The blind spot detection calibration normally occurs automat‐

ically.

♦

Static calibration is only required when there is a DTC memory

entry.

Tightening Specifications

♦ Refer to

⇒ “13.1.1 Overview - Blind Spot Detection, Sedan”,

13.3.2

Blind Spot Detection Control Module -

J1086- / Blind Spot Detection Control

Module 2 - J1087- , Removing and In‐

stalling, Wagon

Removing

– Disconnect the connector -3-.

– Remove the nuts -2- and bolts -4-.

– Remove the Blind Spot Detection Control Module - J1086- /

Blind Spot Detection Control Module 2 - J1087- with the brack‐

et -1-.