Toyota Automatic Transmission A340 Series. Repair Manual - part 21

AT5761

AT5797

D5002

No.

Thickness

No.

Thickness

26

3.3 (0.130)

11

3.8 (0.150)

25

3.5 (0.138)

23

3.9 (0.154)

12

3.6 (0.142)

None

4.0 (0.157)

24

3.7 (0.146)

Inside

Outside

Bearing and

race

37.1 (1.461)

59.0 (2.323)

Inside

Outside

Bearing

26.0 (1.024)

46.8 (1.843)

Race

24.2 (0.953)

47.8 (1.882)

Inside

Outside

Race

27.1 (1.067)

41.8 (1.646)

AT5768

mm (in.)

mm (in.)

mm (in.)

HINT: There are seven different thickness for the flange.

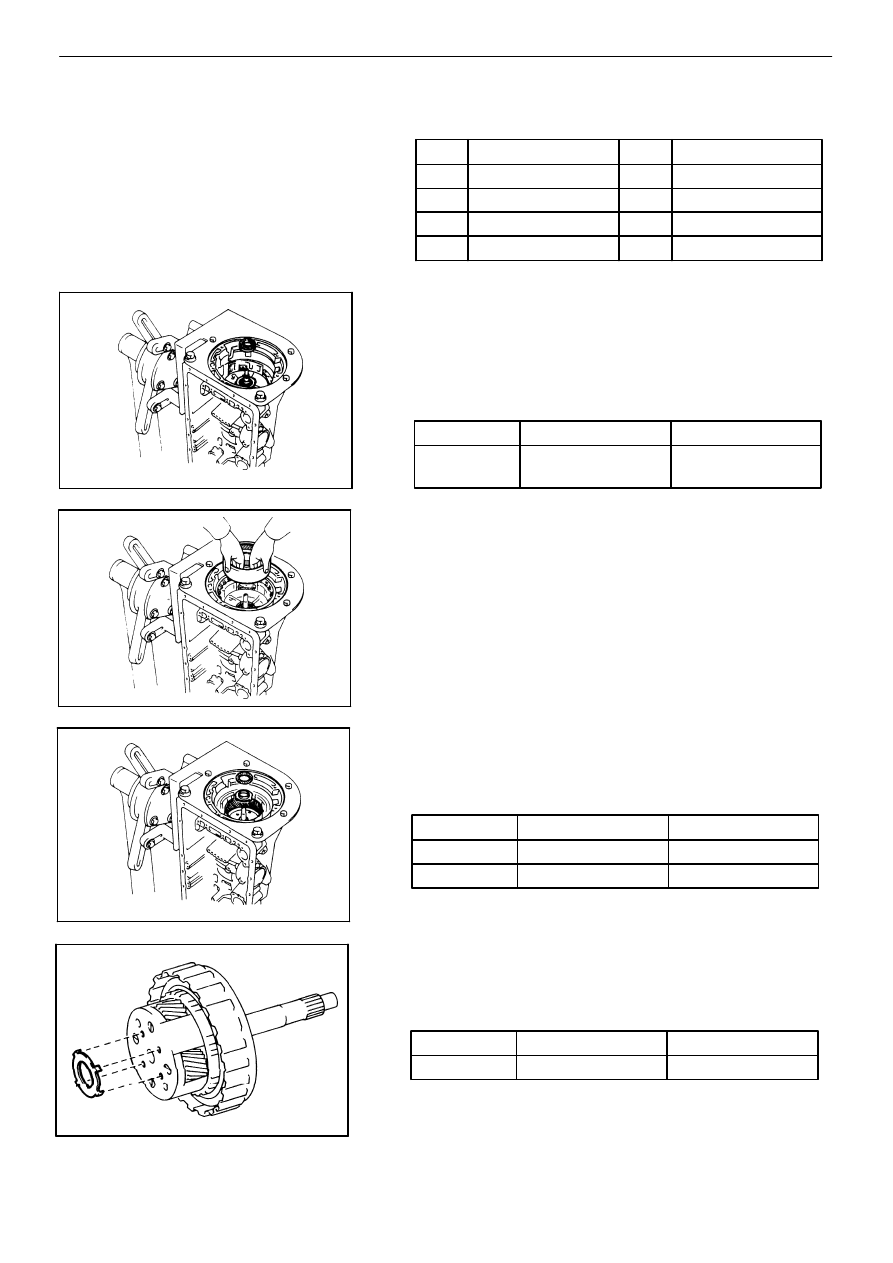

22. INSTALL OVERDRIVE PLANETARY GEAR UNIT

WITH OVERDRIVE DIRECT CLUTCH AND ONE−WAY

CLUTCH

(a)

Coat the assembled bearing and race with petro-

leum jelly and install it onto the overdrive support.

HINT: Assembled bearing and race diameter

(b)

Install the overdrive planetary ring gear.

(c)

Coat the bearing and race with petroleum jelly

and install them onto the planetary ring gear.

HINT: Bearing and race diameter

(d)

Coat the race with petroleum jelly and install it

onto the planetary gear.

HINT: Race diameter

mm (in.)

−

AUTOMATIC TRANSMISSION (A340F)

Installation of Component Parts

AT−157