Toyota Automatic Transmission A340 Series. Repair Manual - part 20

AT5785

AT5776

AT5786

SST

AT8223

AT7893

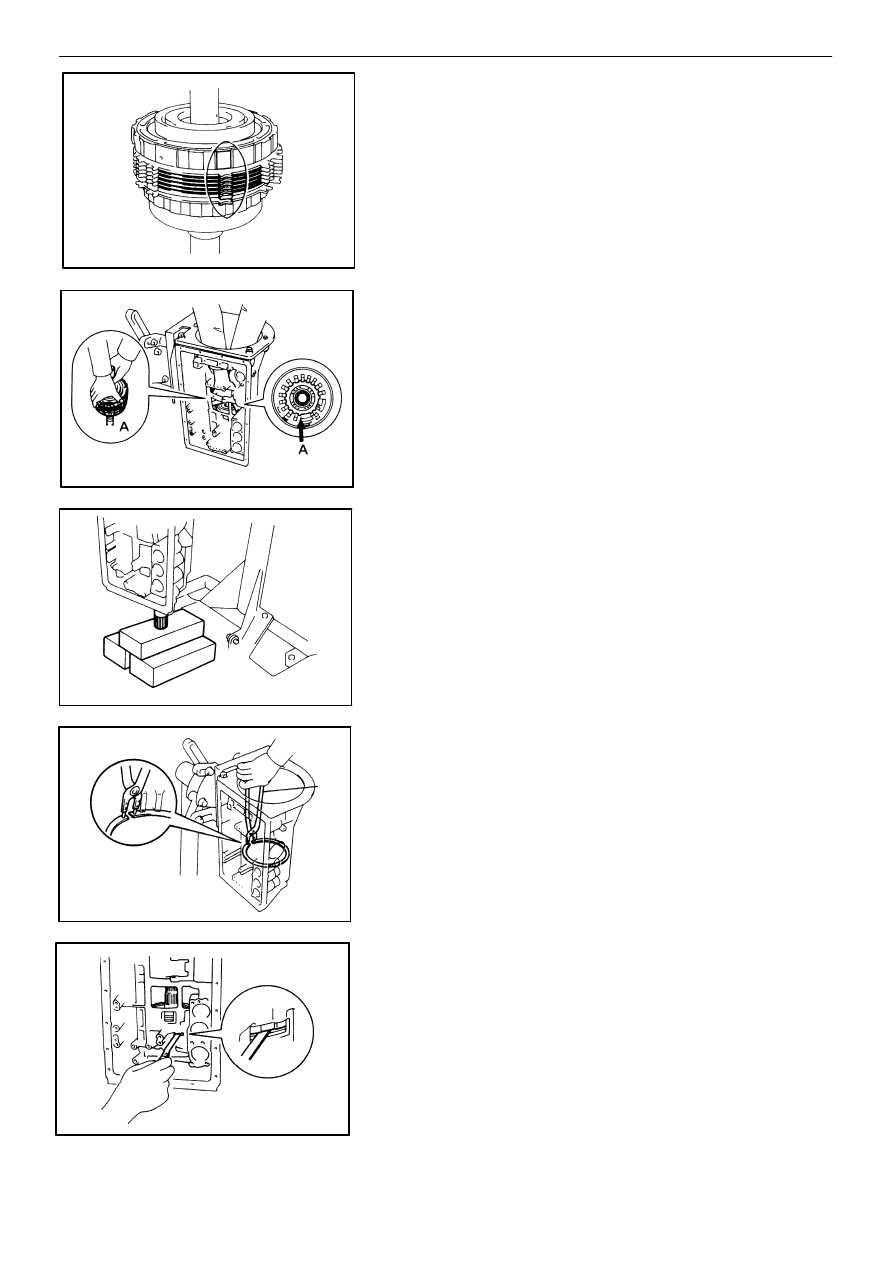

(f)

Align the teeth of the second brake drum, flange,

discs and plates as shown in the figure.

(g)

Align the splines of the transmission case and the

assembled rear planetary gear, second brake

drum, first and reverse brake pack and output

shaft, indicated by A.

(h)

Hold the output shaft with wooden blocks or

equivalents.

(i)

Using SST, install the snap ring.

SST

09350−30020 (09350−07060)

5.

CHECK PACK CLEARANCE OF FIRST AND REVERSE

BRAKE

Using a feeler gauge, measure the clearance between

the plate and second brake drum as shown in the figure.

Clearance: 0.50 − 1.02 mm (0.0197 − 0.0402 in.)

If the values are nonstandard, select another flange.

−

AUTOMATIC TRANSMISSION (A340F)

Installation of Component Parts

AT−149