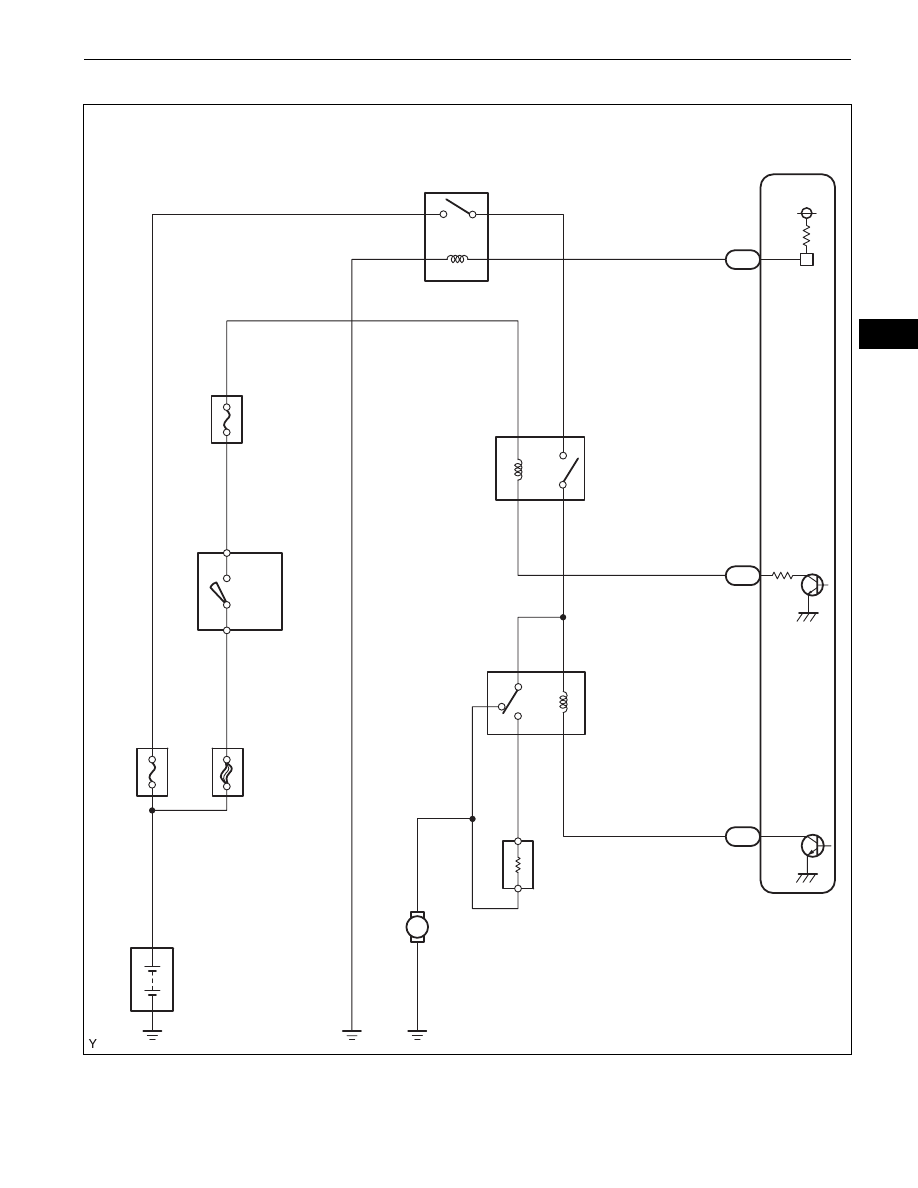

Toyota FJ Cruiser (GSJ 10, 15 series). Instruction - part 54

1GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES–171

ES

WIRING DIAGRAM

M

Battery

AM2

EFI

AM2

IG2

IGN

Ignition Switch

EFI

ECM

MREL

C/OPN

Fuel Pump Resistor

FC

FPR

Fuel Pump

FUEL PUMP

1

3

2

5

1

3

2

5

3

1

5

2

4

1

2

4

5

L5

A13

30

B3

10

E47

8

E47

A1

6

7

2

1

2

1

A133414E02