Toyota FJ Cruiser (GSJ 10, 15 series). Instruction - part 53

1GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES–167

ES

(a) Connect an intelligent tester to the DLC3.

(b) Turn the ignition switch ON and turn the tester ON.

(c) Clear DTCs (See page

).

(d) Switch the ECM from normal mode to check mode using

the tester (See page

(e) Start the engine and warm it up with all the accessories

switched OFF.

(f) Drive the vehicle at between 38 mph and 75 mph (60 km/h

and 120 km/h) and at an engine speed of between 1,400 rpm

and 3,200 rpm for 3 to 5 minutes.

HINT:

If the system is still malfunctioning, the MIL will be illuminated

during step (f).

NOTICE:

If the conditions in this test are not strictly followed, no

malfunction will be detected.

NEXT

(a) Connect an intelligent tester to the DLC3.

(b) Turn the ignition switch ON and turn the tester ON.

(c) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT CODES.

(d) Read DTCS.

15

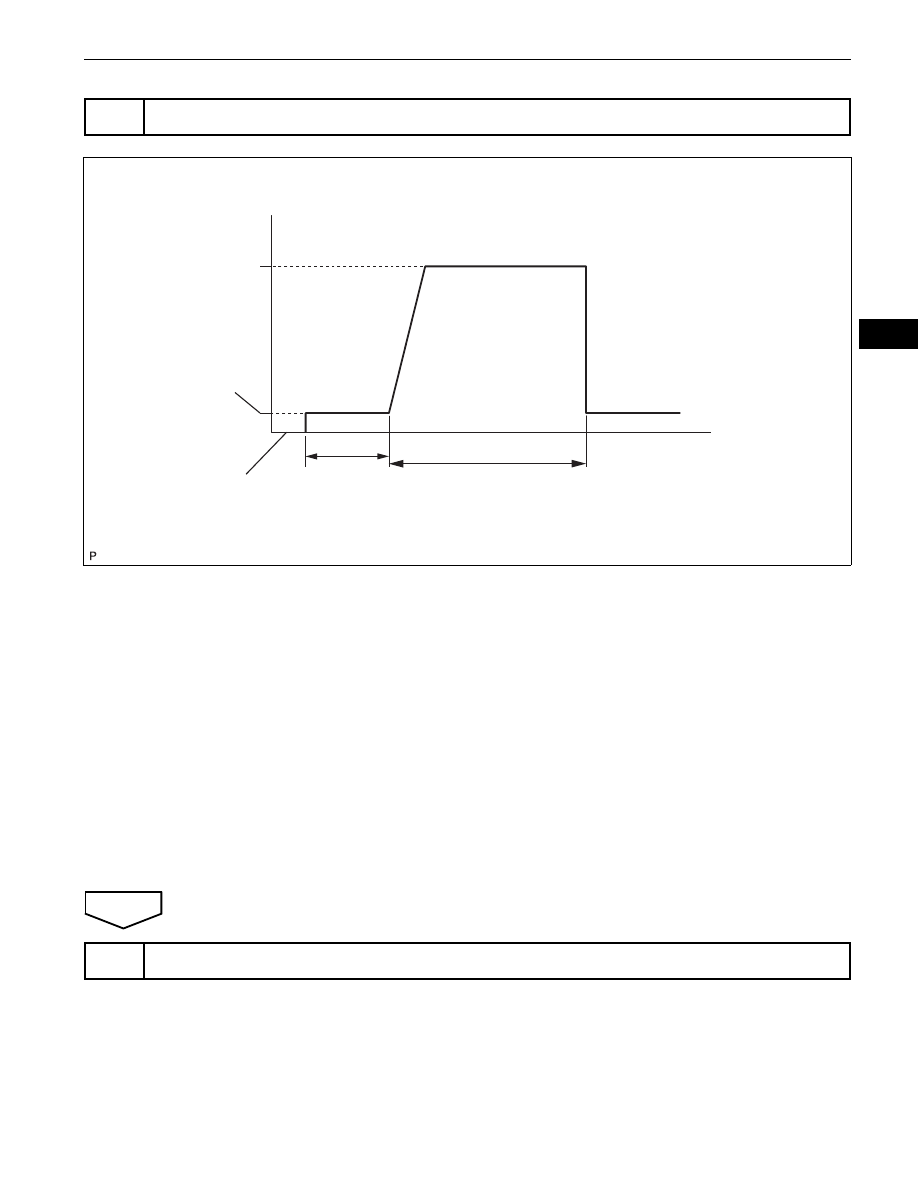

PERFORM CONFIRMATION DRIVING PATTERN

Ignition Switch OFF

Idling

Between

38 and 75 mph

(60 and 120 km/h)

Vehicle Speed

(e)

(f)

Warming up

3 to 5 minutes

Time

(a), (b), (c), (d)

A115372E10

16

CHECK WHETHER DTC OUTPUT RECURS (DTC P0171, P0172, P0174 OR P0175)