Suzuki Grand Vitara JB627. Manual - part 222

5A-72 Automatic Transmission/Transaxle:

DTC Troubleshooting

DTC P2764: Torque Converter Clutch (TCC) Circuit Low

S6JB0B5104045

Wiring Diagram

Refer to “DTC P2763: Torque Converter Clutch (TCC) Circuit High”

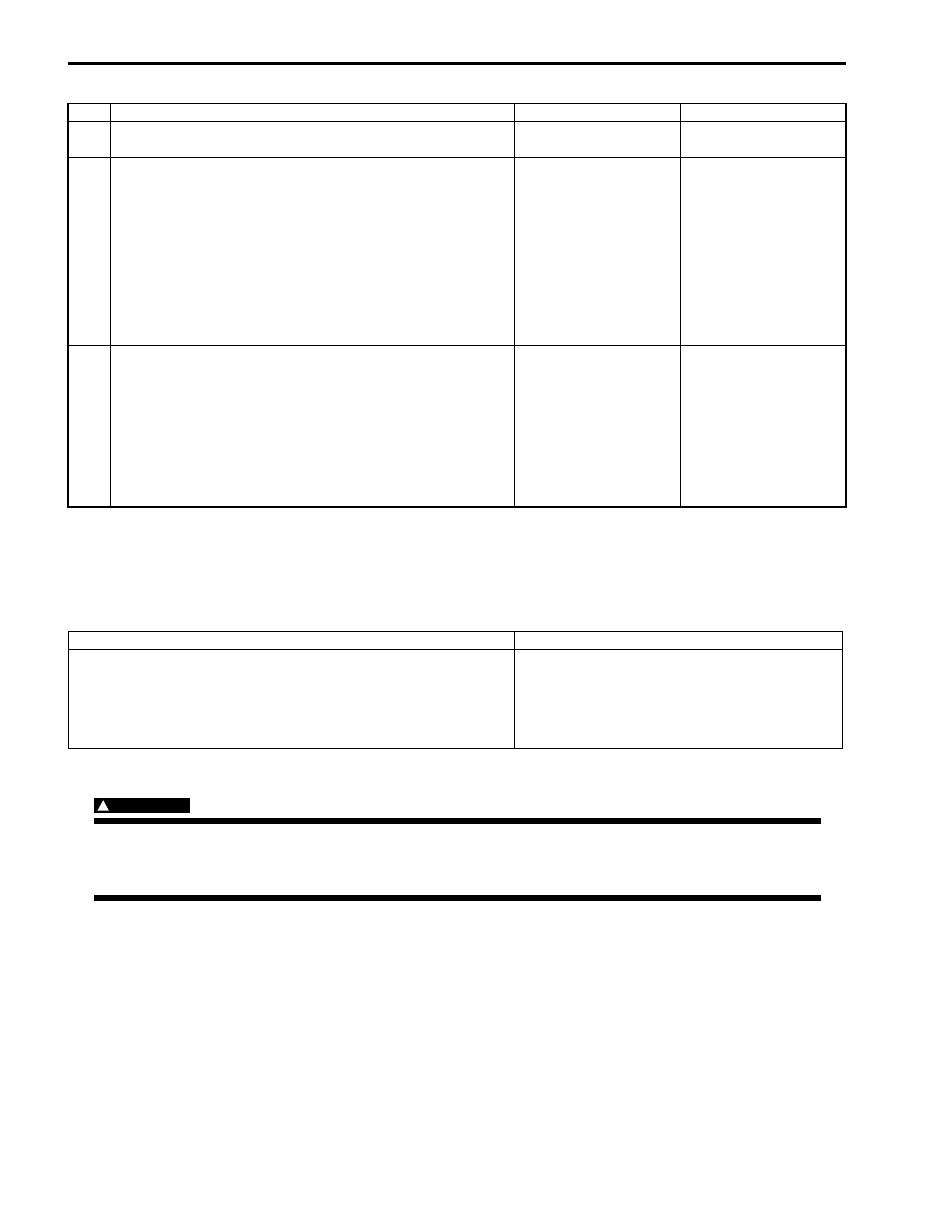

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING

!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and tester, on a level road.

1) Connect scan tool to DLC with ignition switch OFF.

2) Clear DTCs in TCM and ECM memories by using scan tool.

3) Start engine.

4) Keep engine running at idle speed in “P” range for 20 seconds or more.

5) Check DTC, pending DTC and freeze-frame data.

Step

Action

Yes

No

1

Was “A/T System Check” performed?

Go to Step 2.

Go to “A/T System

Check”.

2

Check TCC pressure control solenoid valve circuit for

power supply short

1) Disconnect TCM connectors.

2) Check for proper connection to TCM at terminal “E92-3”

and “E92-5”.

3) If connection is OK, turn ignition switch ON and measure

voltage between terminal “E92-3” of disconnected

harness side TCM connector and ground.

Is it 0 – 2 V?

Go to Step 3.

TCC pressure control

solenoid valve control or

ground circuit is shorted

to power supply circuit.

If circuit is OK, go to

Step 3.

3

Inspection TCC pressure control solenoid valve

1) Inspection TCC pressure control solenoid valve referring

Is check results satisfactory?

Intermittent trouble or

faulty TCM. Check for

intermittent trouble

referring to “Intermittent

and Poor Connection

Inspection in Section

00”. If OK, substitute a

known-good TCM and

recheck.

Replace TCC pressure

control solenoid valve

referring to

“Transmission Fluid

Temperature Sensor

Removal and

Installation”.

DTC Detecting Condition

Trouble Area

Voltage of TCC pressure control solenoid valve TCM terminal is

low although TCM is commanding TCC pressure control solenoid

to turn ON.

(1 driving cycle detection logic)

• TCC pressure control solenoid valve circuit

open or shorted to ground.

• Malfunction of TCC pressure control solenoid

valve

• TCM